Contents

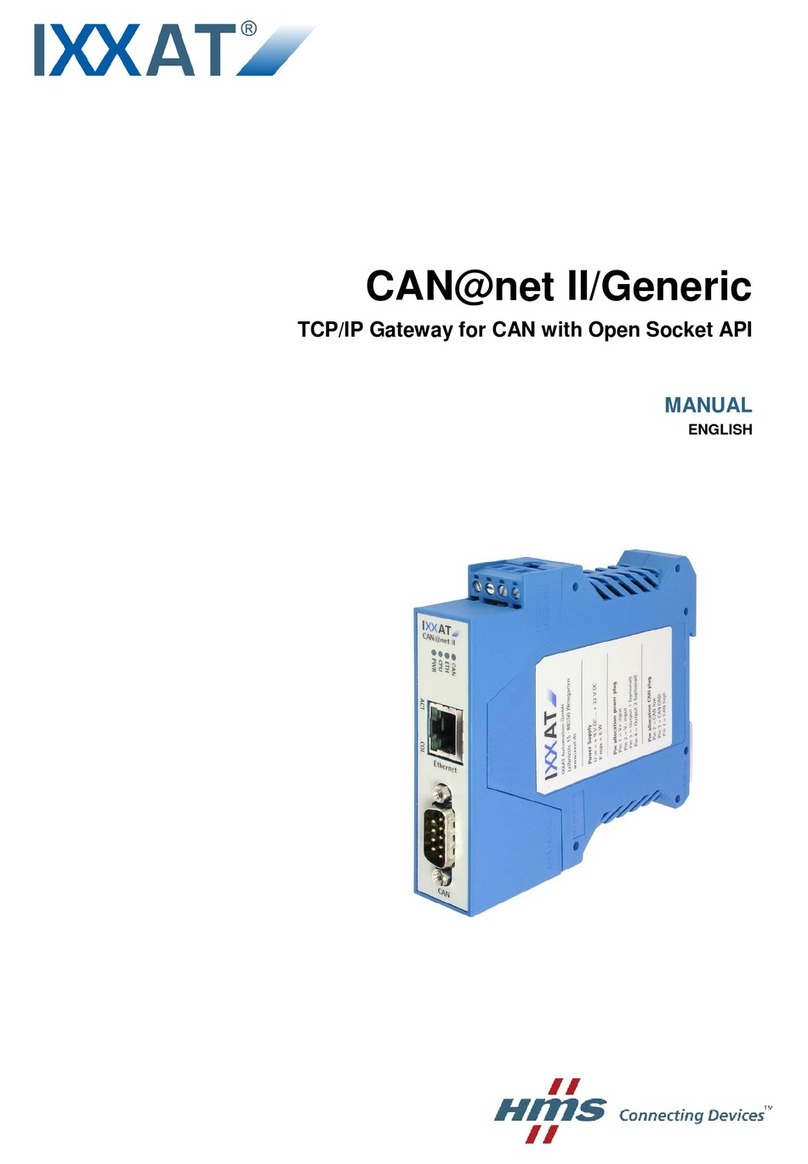

1Introduction................................................................................5

1.1 Overview ............................................................................. 5

1.2 Performance features ......................................................... 5

1.3 Block diagram ..................................................................... 6

2Installation of the device ............................................................7

2.1 Connections of the CAN@net............................................. 7

2.2 Preparation of configuration.............................................. 7

2.3 Commissioning a configured device .................................. 8

3Configuration .............................................................................9

3.1 Overview of the parameters ............................................. 10

3.2 Starting the configuration................................................ 10

3.3 Settings of the network parameters ................................ 11

3.3.1 DHCP setting ..........................................................................11

3.3.2 Configuration of the IP address ...............................................11

3.3.3 Configuration of the subnet mask ...........................................12

3.3.4 Configuration of the gateway address .....................................12

3.4 Hardware Configuration ................................................... 13

3.4.1 Setting the baud rate for the serial interface ............................13

3.4.2 Setting the delay time of the configuration dialog ...................14

3.5 Saving the changed data .................................................. 14

4Software Update.......................................................................15

4.1 Update via the serial interface.......................................... 15

5Pin assignment .........................................................................16

5.1 Voltage supply .................................................................. 16

5.2 CAN ................................................................................... 16

5.3 RS232 ................................................................................ 17

5.4 Ethernet ............................................................................ 17

6Displays.....................................................................................18

6.1 Power LED ......................................................................... 18

6.2 Serial LED .......................................................................... 18

6.3 CAN LED ............................................................................ 18

6.4 Ethernet LED ..................................................................... 18

Appendix..........................................................................................19

Copyright IXXAT Automation GmbH CAN@net Manual, Version 1.7

3