Contents

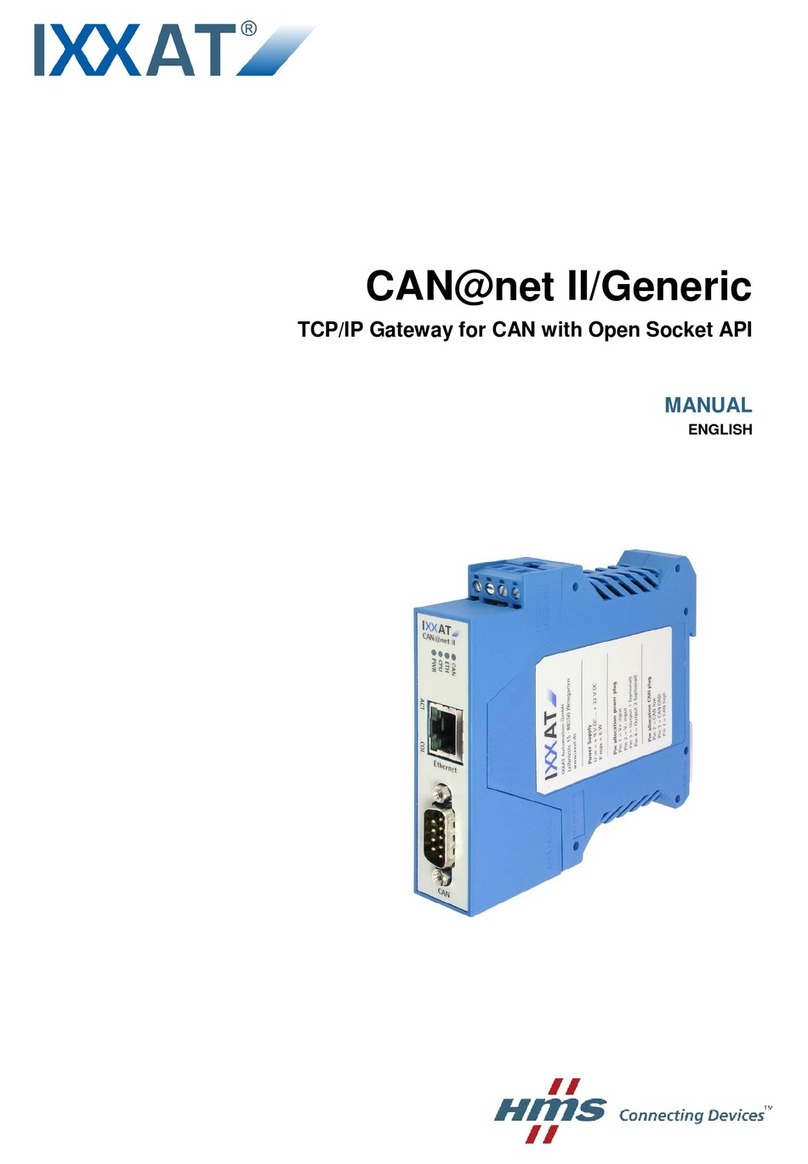

1Introduction..................................................................................5

1.1 Overview ............................................................................... 5

1.2 Features ................................................................................ 5

1.3 Versions ................................................................................ 5

1.4 Block diagram....................................................................... 6

1.5 Support................................................................................. 7

1.6 Returning hardware ............................................................. 7

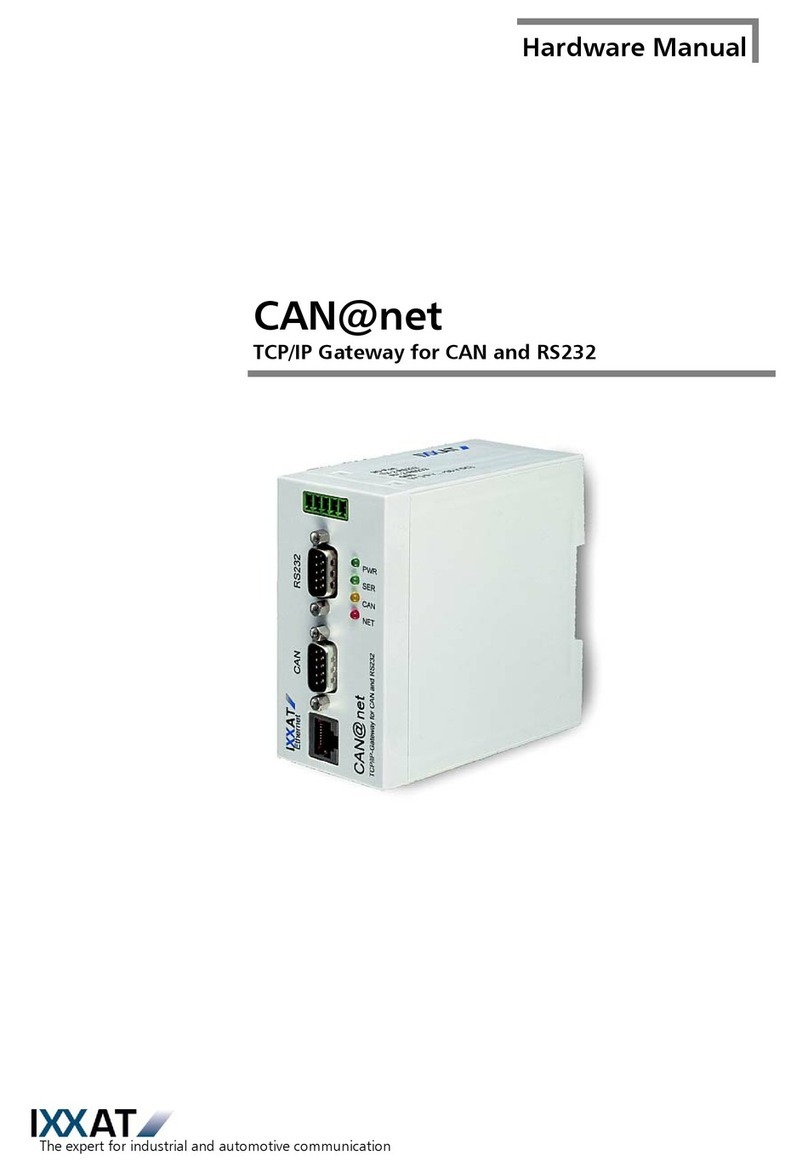

2Aluminum Version ........................................................................8

2.1 Pin Allocation........................................................................ 8

2.1.1 Voltage supply (X1).....................................................8

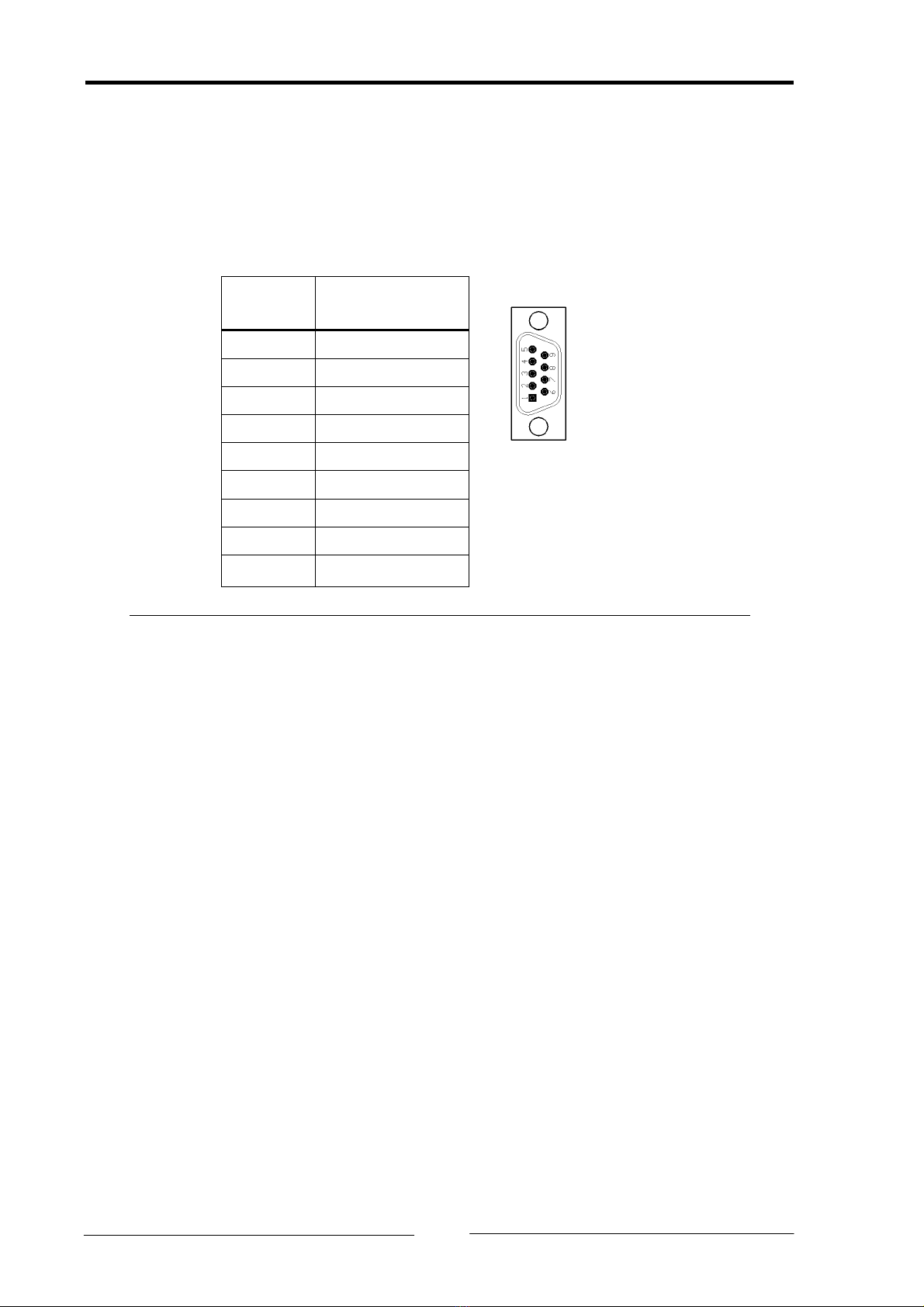

2.1.2 Serial interface RS232 (X2) ...........................................9

2.1.3 CAN 1 (X3) ...................................................................9

2.1.4 CAN 2 (X4) .................................................................10

2.2 Ground connections ........................................................... 10

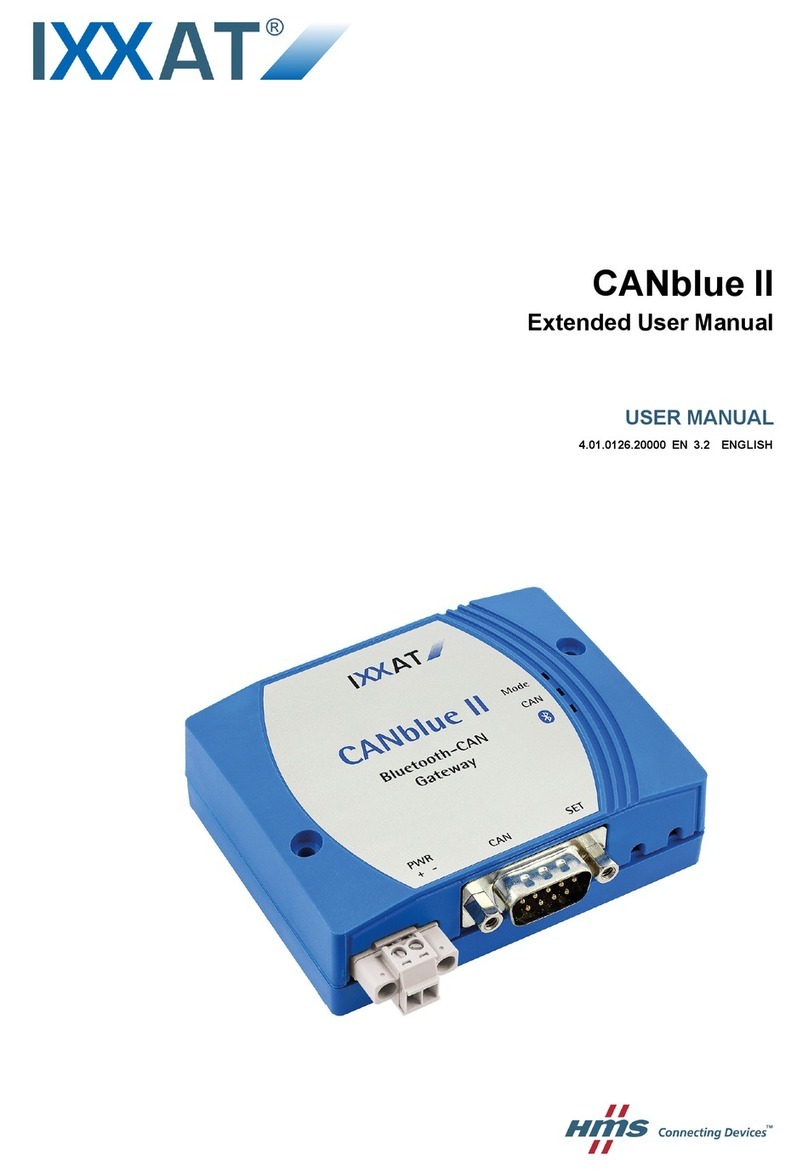

3Industrial DIN-Rail Version .........................................................11

3.1 Pin allocation ...................................................................... 11

3.1.1 Voltage supply (X1)...................................................11

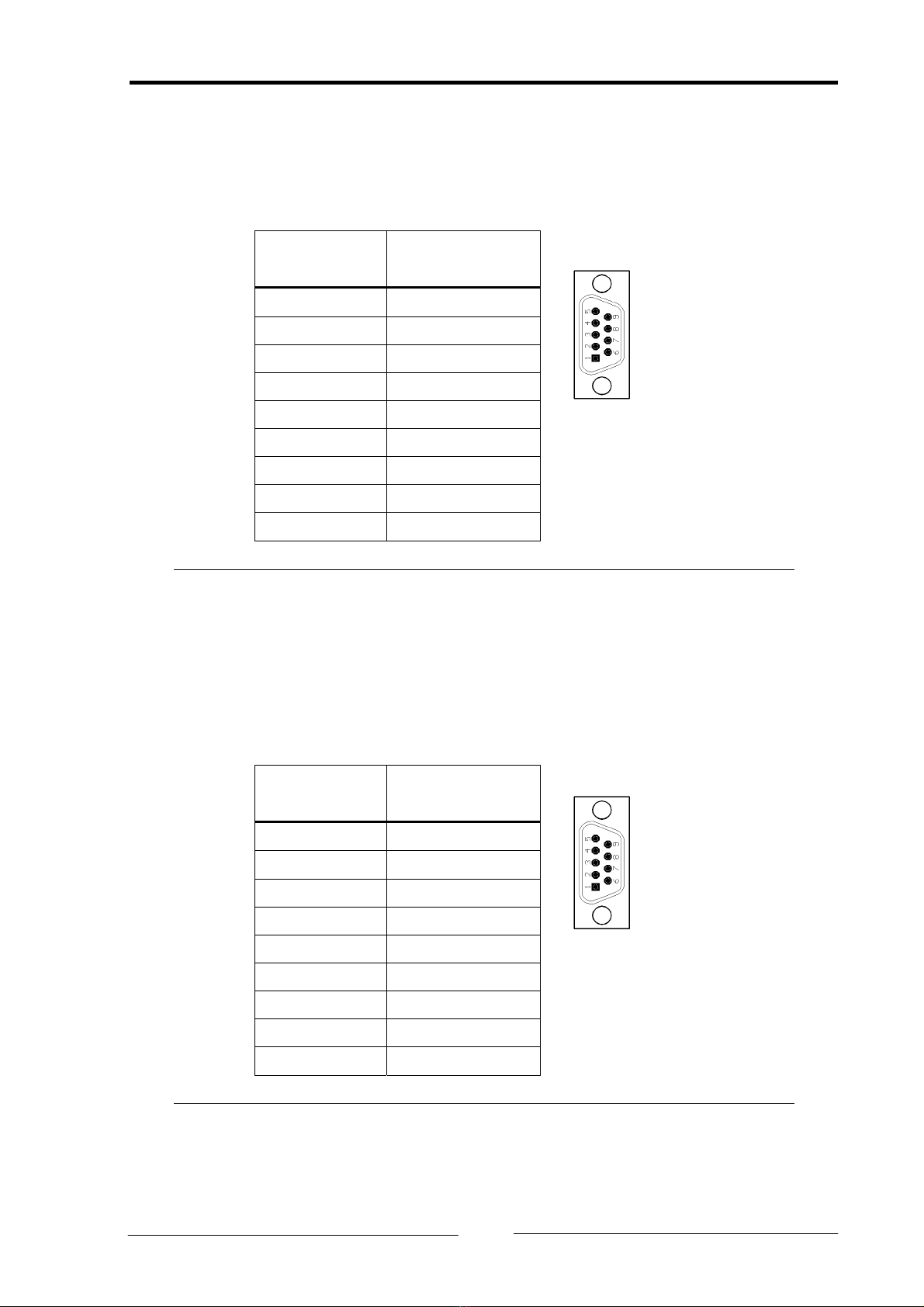

3.1.2 Serial interface RS232 (X2) ........................................12

3.1.3 CAN 1 (X3) .................................................................12

3.1.4 CAN 2 (X4) .................................................................13

3.2 Ground connections ........................................................... 13

4Displays.......................................................................................14

4.1 Normal mode (Gateway mode).......................................... 14

4.1.1 PWR - LED ..................................................................14

4.1.2 CAN1/CAN2 LED.........................................................14

4.1.3 COM LED....................................................................14

4.2 Automatic baudrate detection ........................................... 14

4.2.1 PWR LED ....................................................................14

4.2.2 CAN1/CAN2 LED.........................................................14

5Functional description................................................................15

5.1 Introduction........................................................................ 15

5.2 Data Structure of the Configuration Files .......................... 16

5.2.1 General settings [General] ........................................18

Copyright IXXAT Automation GmbH CANbridge - Manual, V1.4

3