JABLOTRON ALARMS a.s.

Pod Skalkou 4567/33 46601 Jablonec n. Nisou

Czech Republic www.jablotron.com

||

|

The JA-122PW/JA-122PW (G) Bus dual PIR and MW motion detector

JA-122PW/JA-122PW (G) 1/2 MON51101

This product is a bus component of the JABLOTRON 100+ system.

It is designed to detect human body movement inside buildings. A high

immunity to false alarms is reached thanks to the combination of PIR and

microwave (MW) detection. The detector works like a classic PIR detector,

however when PIR detects movement in a guarded area, the MW part

is activated and confirms the previous PIR activation. Only then an alarm is

triggered and is sent to the control panel. The JA-122 PW features a white

lens that provides standard white light immunity as defined by the norm (up to

6000 lux). The JA-122PW (G) detector features a grey lens that provides

increased white light immunity, way above the requirements defined by the

norm (up to 10000 lux). This lens helps to reduce false indication of alarms

caused by for example: car headlight refraction, the setting sun, lightning or

reflective surfaces. The immunity to false alarms can be set at two levels, PIR

and MW. The detector operates with a pulse reaction (only indicates its

activation) and takes up a single position in the system. This detector is

intended to be installed by a trained technician with a valid certificate issued

by an authorised distributor.

Installation

Given the principles and detection characteristics of the MW detector, the

best results can be achieved when the detector is installed in a corner of

a room. No moving objects (e.g. waving curtains above a radiator or animals)

should be in the detector’s field of vision. There should be no obstacles in

front of the detector which could obstruct it’s view and it should not be

installed near metal objects (they could affect the MW field). It is also not

possible to install two or more detectors in a single area, as the MW

transmitters could affect each other.

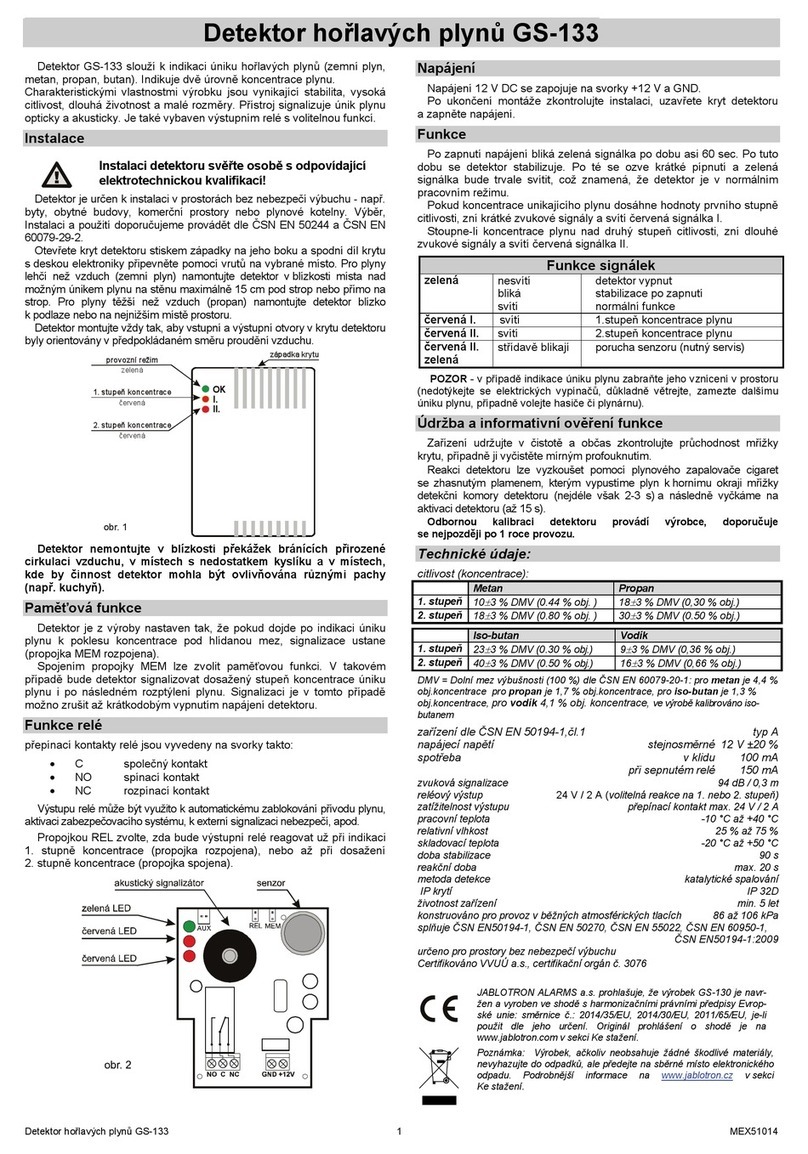

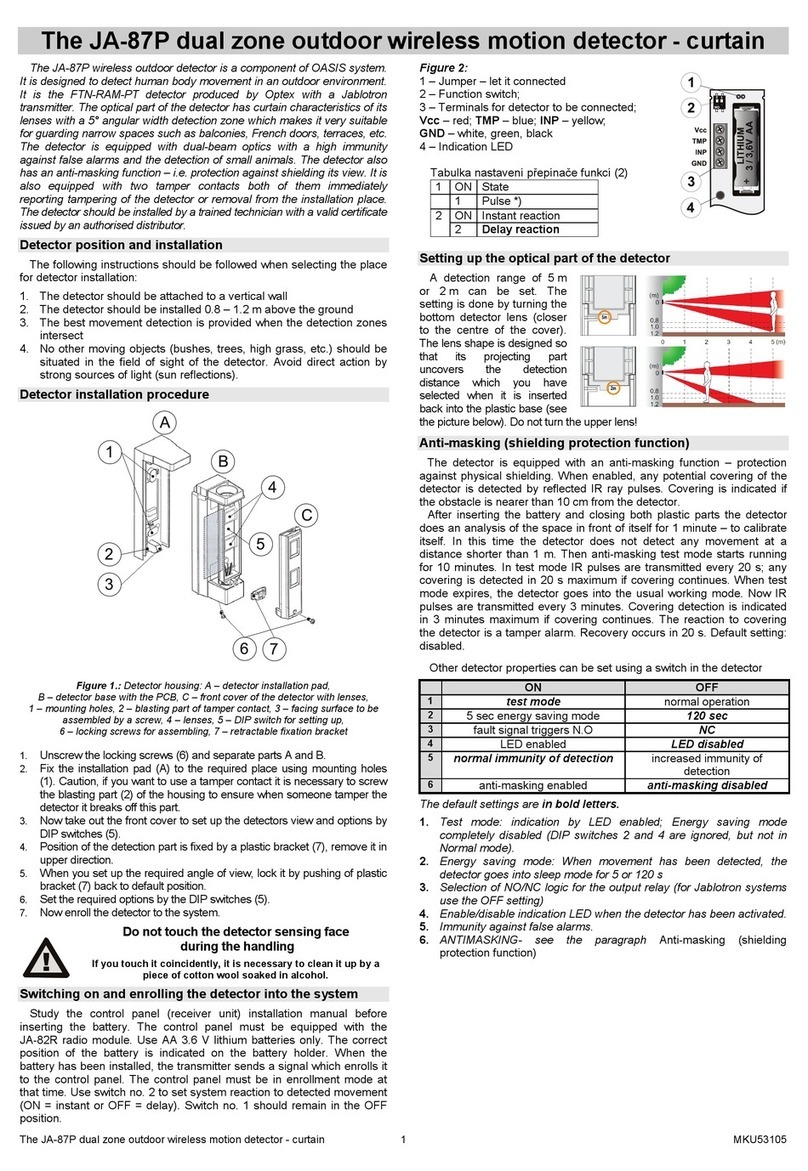

Fig 1: 1 – wiring knockout holes; 2 – digital bus terminals; 3 – MW sensor;

4 – production code; 5 – detector state indicators; 6 – The JA-191PL external tamper

connector; 7 – PIR sensor; 8 – tamper contact; 9 – PCB tab; 10 – light guide; 11 – PIR lens;

12 – fixing screw hole; 13 – cover tab; 14 – MW sensor protective divider

1. Open the detector cover by pushing the tab (13). Avoid touching the PIR

sensor inside (7) – you could damage it.

2. Take out the PCB – It is held in place by tabs (9) at the lower part of the

cover.

3. Punch through the (1) holes for the screws and the cable in the plastic

base. The recommended detector installation height is 2.5 m above the

floor. In order to fully take advantage of device removal tamper detection,

it is necessary to utilize the screw hole surrounded by perforation.

4. Insert the bus cable through the holes (1) and attac h the plastic base to

the wall using screws (vertically, with the cover tab facing downwards)

Always switch the power off before

connecting the detector to the system bus.

5. Put the PCB back and connect the bus cable to the terminals (2).

6. Bus cables must not reach beyond the divider (14) that protects the MW

sensor. Cables reaching into the area beyond the divider can negatively

impact the functionality of the MW sensor.

7. Proceed according to the control panel installation manual. The control

panel must be in service mode. Basic procedure:

a. When the device is powered, the yellow LED starts flashing

repeatedly to indicate that the module has not been enrolled into the

system, simultaneously, the red LED glows (for up to 3 min –

detector stabilisation is in progress).

b. Go to the F-Link software, select the required position in the

Devices tab and launch enrollment mode by clicking on the Enroll

button.

c. Click the „Scan/add new BUS devices“button and double-click the

detector which you wish to enroll from a list of detected devices.

Enrollment can also be performed by pressing the (8) tamper button

inside the detector. Once the detector has been enrolled, the yellow

LED will cease to glow.

8. Close the detector cover. In order to be fully compliant with regulations,

it is necessary to fix the cover in place with the use of a fixing screw.

(12).

Notes:

-The detector can also be enrolled into the system by entering its

production code in the F-link program. The serial number is on a label

with a bar code which is placed inside the detector (4). All numbers must

be entered (example: 1400-00-0000-0001).

-If you wish to remove the detector from the system, delete it from its

position in the control panel.

Detector internal settings

The detector’s internal settings can be adjusted in the Devices tab of the

F-Link software. Use the Internal settings button, at the same position as

the detector, to open a dialog window where you can set the following (factory

settings are marked with *):

LED detector indication:turns off*/on movement indication by the means

of a red LED (1) during operation. During service mode the LED indicates

every movement regardless of this setting.

PIR immunity level:determines the level of immunity to false alarms.

Standard* combines basic immunity with a fast sensor reaction. Increased

has stronger immunity with a slower reaction time.

MW immunity level:determines the level of analysis performed by the MW

motion detector. Standard* combines basic immunity with a fast sensor reaction.

Increased has stronger immunity and provides a slower reaction time.

MW sensitivity:100%*, 75%, 50%, 25%. In some instances the

microwave detection is capable of detecting movement behind solid obstacles

– such as walls, glass panels, plasterboard walls, etc. It is recommendable to

perform

a test in the test mode – MW,and in case of any unwanted triggers, gradually

decrease the sensitivity.

MW activation:Any set* / Full / Always / Never. By default, PIR activation

confirmed by MW detector is turned on both in partial and full setting when

the system is set. In an unset state the MW detection is turned off (therefore

the detector is activated in an unarmed state by the PIR sensor). By changing

the setting to Full, MW detection is active only if a section is fully set. MW

detection is disabled if a section is partially set or in an unset state. If the third

setting is chosen, the MW detector is always activated, even in an unarmed

set state. (Please note, this setting can drastically impact detector

battery life expectancy, depending on the number of activations).

Confirmation by MW detection can be c ompletely turned off by choosing the

Never option, in which case the detector behaves like a standard PIR

detector.

Sensor of tearing-off from the wall: turns the detection off*/on on the

additional tamper sensor featured on the JA-191PL PIR jointed bracket.

Completely disable PIR detection:YES/NO*. If the installation requires it

(e.g. a long corridor where PIR detection is insufficient), it is possible to

completely disable PIR motion detection and therefore turn the detector into

a MW detector with the use of this setting.

Test mode: The PIR+MW and MW buttons are intended to be used for

detector testing. In order to initialize the test mode, the control panel must be

in service mode. By pressing the PIR+MW button, the detection test mode of

regular operation is initiated. By pressing the MW button, the MW detection

test mode is initiated, which allows for a thorough control of detection

sensitivity in order to prevent the possibility of initiating a false alarm. In both

modes, detection is indicated by the flash of a red LED light, at the same time

a signal is transmitted to the control panel – which can be seen on the

Diagnostics tab within F-Link. The test mode is exited either by pressing the

PIR+MW button or leaving the internal settings tab.

Detector testing

If the control panel is in service mode, every movement registered by the

detector is indicated by an LED. By exiting the service mode, the control

panel will enter the operational mode, which is set within the internal settings.

Individual detector activations can be seen within the F-Link program

under the Diagnostics tab.

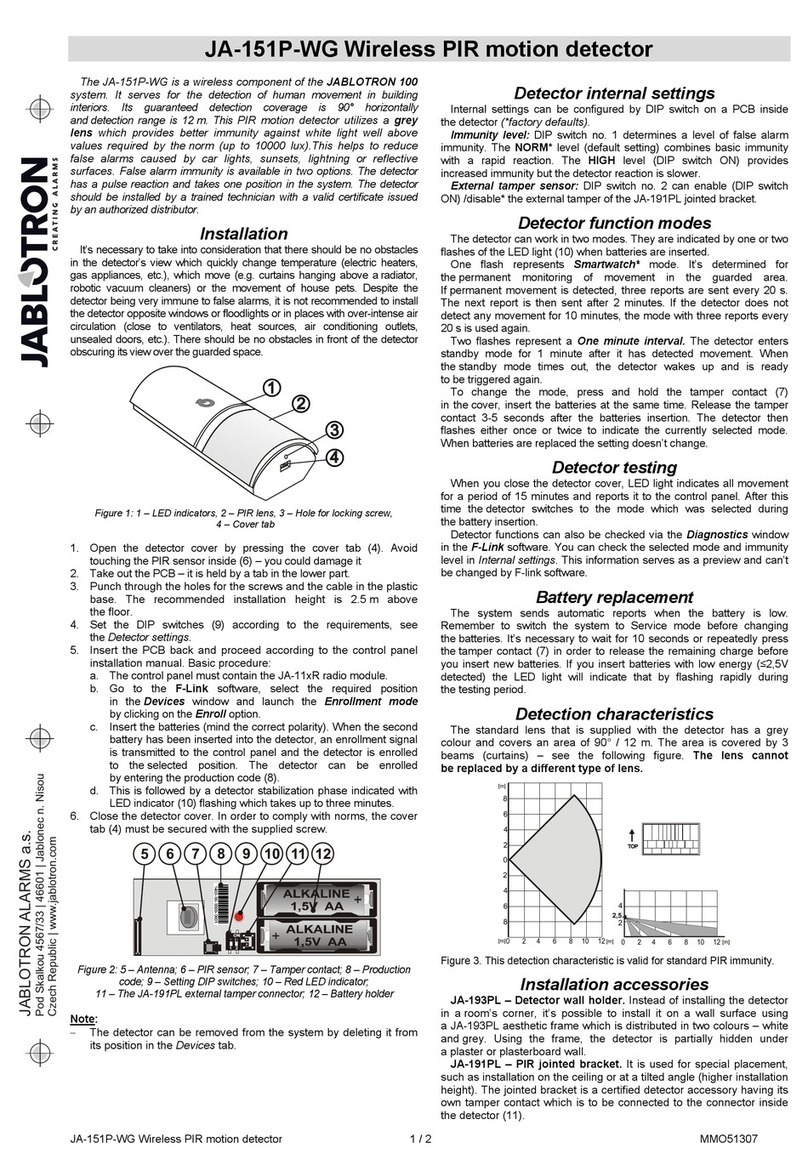

The PIR sensor is equipped with a 90°/12m lens – white characteristic. For

coverage see - Fig 2.

Fig 2: Detection characteristics

The MW sensor reacts to movement within the range of 0 m to 12 m –

grey characteristic. The MW sensor can in certain instances detect movement

behind non-metallic solid objects, (such as: walls, doors, glass, etc.). Due to