JABLOTRON ALARMS a.s.

Pod Skalkou 4567/33 46601 Jablonec n. Nisou

Czech Republic www.jablotron.com

||

|

The JA-152SHM wireless shock or tilt detector with magnetic

contact

JA-152SHM 1 / 2 MLB55202

The product is a wireless component of the JABLOTRON system.

It is a combined shock or tilt detector with external input. It occupies two

separate enrolment addresses in the control panel. The product can be

installed by a trained technician with a valid certificate issued by an authorized

distributor.

The product is compatible with the JA-103K, JA-107K or above.

Installation

It is always necessary to have a look at how the detector is used.

We do not recommend installing the detector directly onto metal surface

that can negatively affect wireless communication with a control panel.

The detector responds to vibrations and shocks caused by the pad to

which it is mounted when the shock mode is selected. The mechanical

contact must be sufficient for a good transmission of shocks to

the detector. The detector should be placed in locations where stronger

shocks are expected – i. e. further away from fixed edges of windows or

door frames.

When in a tilt mode, the detector reacts to a change in its position. –

e. g. on a window casement.

There are two different types of permanent magnets in the package –

a standard magnet in a plastic housing (A) and a ring-shaped magnet (B)

for use in places where there is not enough space for a standard magnet

or for counter-sinking the magnet into a door or window’s inner frame.

The detector activation distance threshold (only applicable to non-

ferromagnetic installation surfaces) is 26 / 17 mm for the Z axis. For other

types of magnets, the detection threshold characteristic may vary.

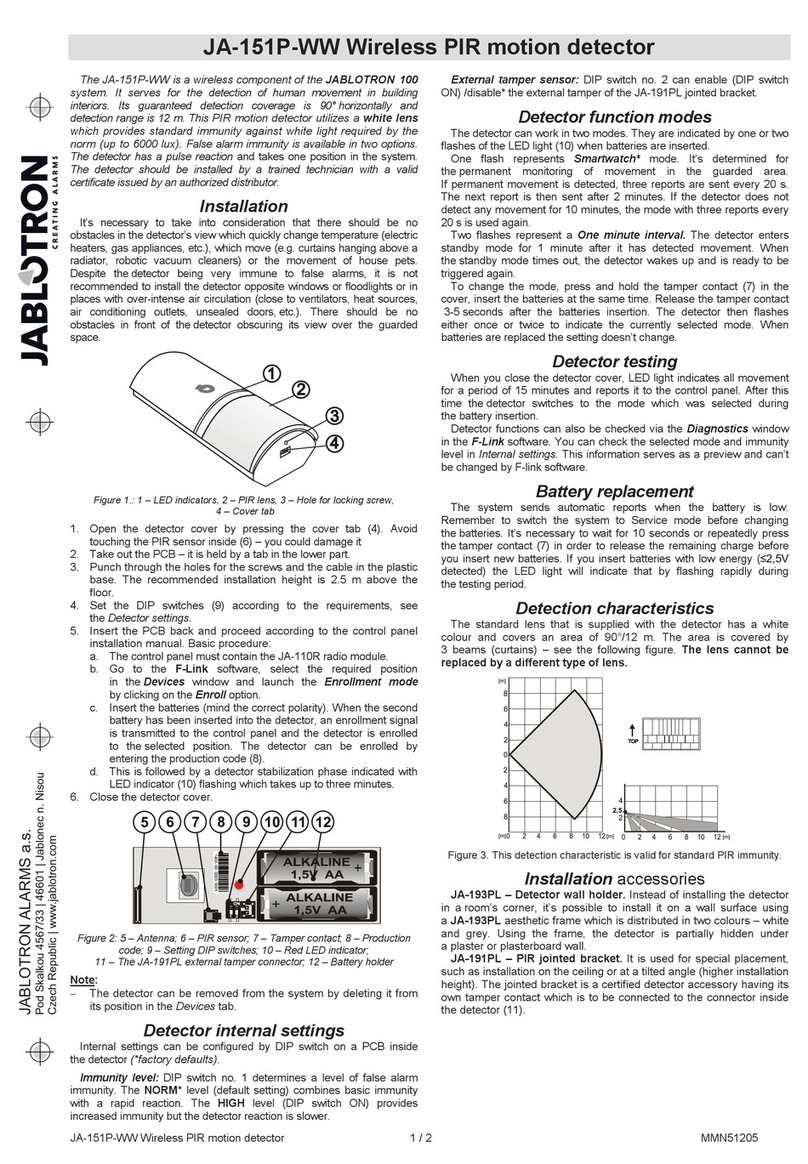

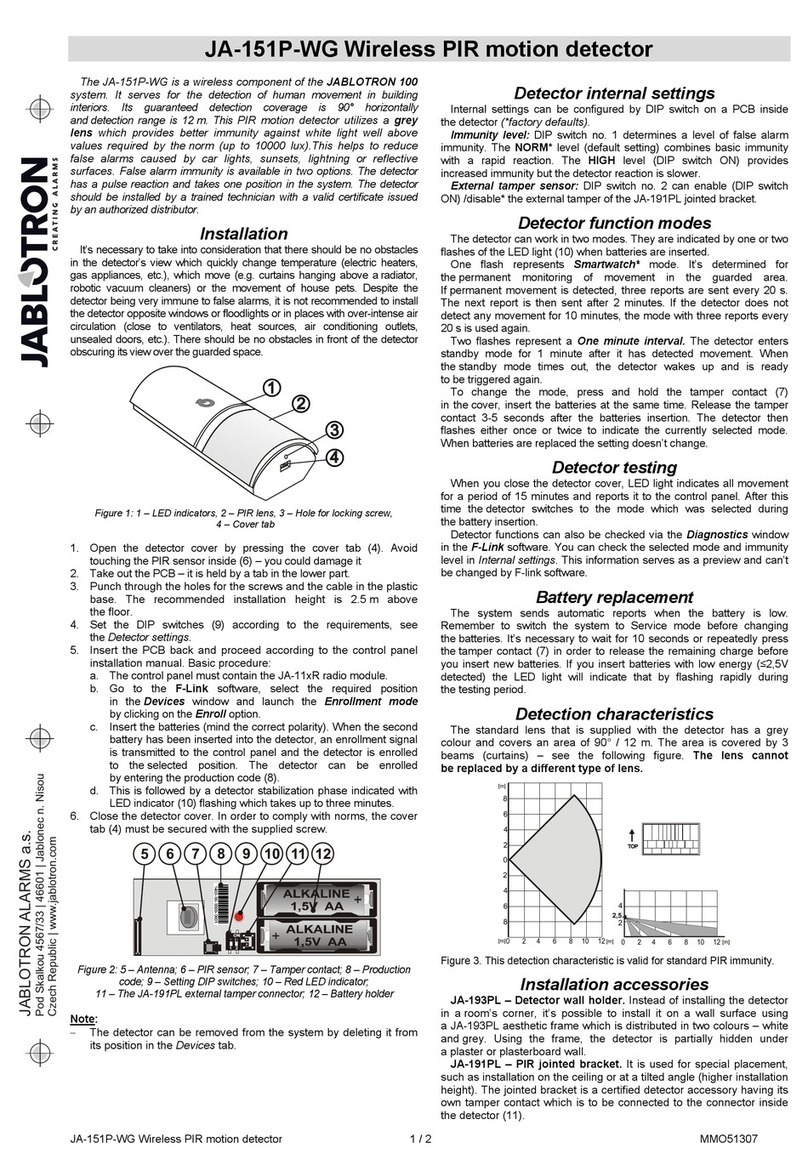

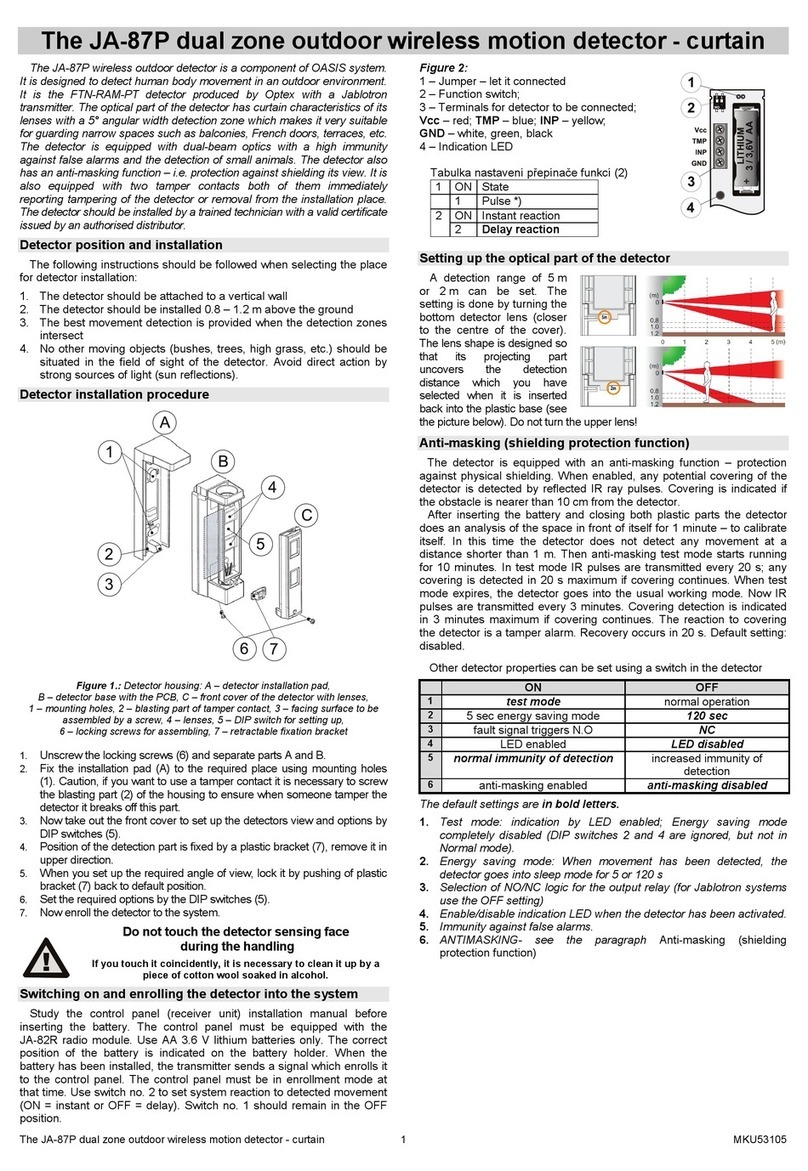

Figure: 1 – place for locking screw, 2 – cover tab, 3 – LED indication,

4 – battery, 5 – serial number, 6 – terminals, 7 – cover tamper contact

Deactivation distance (mm)

Table 1: distances for opening and closing on a non-magnetic base.

Deactivation distance (mm)

Table 2: distances for opening and closing on the magnetic base.

1. Open the detector cover by pressing the cover tab (2).

2. Mount the rear pad onto the required place. If it´s needed, put

the cables through the rear plastic pad. The length of cables to

the detector should not exceed 3 m; choose the place of installation

accordingly.

3. Attach the selected magnet to the moving part of the door (window)

with screws. The lower edge of the standard magnet has to be at

the same height as the lower edge of the detector. It is recommended

to attach the whorl-shaped magnet with a non-magnetic screw from

the package.

4. Connect the wires from external contact to the terminals, if they are

used.

5. Proceed according to the control panel installation manual.

Basic procedure:

a. In the F-link software, select the required position in

the Devices window and launch the enrolment mode by

clicking on the Enrol option.

b. Insert the battery (mind the correct polarity). The enrolment

signal is transmitted when the battery is inserted into

the detector. Note – the detector occupies 2 positions (each

input has its own position). Should the second position be

occupied, it will be automatically overwritten.

6. Close the detector cover.

7. In order to comply with norms, the front cover must be secured with

the supplied locking screw (1).

8. Configure the detector by following the Internal settings chapter in

this manual.

Notes:

−The detector can also be enroled into the system by entering its

serial number (5) into the F-link software (1400-00-0000-0001).

You can find the sticker with serial number under a bar code,

located on the battery holder.

−If only the first input is used, the second input can be deleted by

pressing “Delete” to release the position for another device.

−By deleting the first input position, the module will be deleted

completely.

Detector communication in the system

The detector uses bi-directional asynchronous communication which

allows you to change the internal settings remotely and at the same times

does not consume a lot of battery capacity.

After enrolment to the system, the detector operates in an accelerated

mode, until the service mode is exited (but no longer than 24 h). In this

mode, the detector checks every 90s whether system is still in service

mode or if new settings should be taken over.

In service mode, the detector communicates once every 19 minutes or

with each activation. Therefore, when switching from operational mode to

service mode, it can take up to 19 minutes for the detector to recognize

control panel status or internal settings change. This period can be

reduced by activating the detector or its tamper sensor.

Please note:

It is not necessary to wait 90 s (or 19 min) until the detector confirms

delivery of the new setting, when changes are applied. System

remembers the requested change and forwards the new settings to

the detector during the next period of regular communication.

Internal settings

The detector settings can be set in the Devices tab of the F-link

software. Click on the Internal settings button at the detector’s position

to open a dialogue window where you set (* indicates default settings):

Input 1 - Function: Shock* / Tilt / Disabled

Shock: The device responds to environmental shock input.

Activation of shock:

Turning on the detector option after the 1st shock will ignore any further

shocks for 10 seconds. After this 10 s, there will be a 30 s interval in which

the next possible jolt will be reported as an Input Activation. If no further

shocks occur within these 30 s, the 1st shock will be ignored - no Input

Activation will be reported in the system. By disabling the option, the

detector sends an Input Activation to the system as soon as the 1st shock

is detected.

Sensitivity:Detector sensitivity level. The detector ignores jolts/tilts that

do not exceed the sensitivity setting. Automatic shock sensitivity

adjustment: how to adjust the sensitivity:

To start the calibration from the peripheral, the system must be in

Service mode, then Activate tamper contact (open the plastic cover) and

within 5 seconds deactivate the tamper contact (close the plastic cover).

This procedure will switch on calibration directly from the peripheral -

indication as described below from point 3. When starting calibration from

the detector, the Yellow LED will not be lit (it is only lit if the peripheral has

an open internal setting in the F-Link). Calibration can be terminated by

activating the tamper contact (open the plastic cover).

1. LED off = detector waiting for connection. To continue, activate

the magnet (open and close the window/door)..

2. Yellow LED illuminated = detector has established

a connection. Start calibration to continue.

3. Glow yellow LED + regular double red LED = detector is ready

to start calibration. Activate magnet to continue.