RUN DRY

UTILITY PUPPIES

MODELS:

23920-9403 / 9503 12 / 24V RUN DRY UTILITY PUPPY

23920-9213 / 9313 12 / 24V RUN DRY UTILITY PUPPY

FEATURES:

Continuous rated, heavy duty, dry running pumps for

bilge, deckwash and general purpose use.

lMeets USCG Regulation 183.410 and ISO 8846

MARINE (Ignition protection).

lISO 8849 MARINE (Bilge pump standard).

lBilge debris present no problem to these

bronze bodied, flexible impeller pumps.

lSimple design means fewer wearing

parts.

Run Dry Utility Puppy 23920-9403 / 9503

l390 gph output.

lTwenty minutes dry running (after initial prime).

lSelf priming to 4 ft.

Run Dry Utility Puppy 23920-9212 / 9313

l612 gph output.

lTen minutes dry running (after initial prime).

lSelf priming to 8 ft.

lLong life mechanical seal.

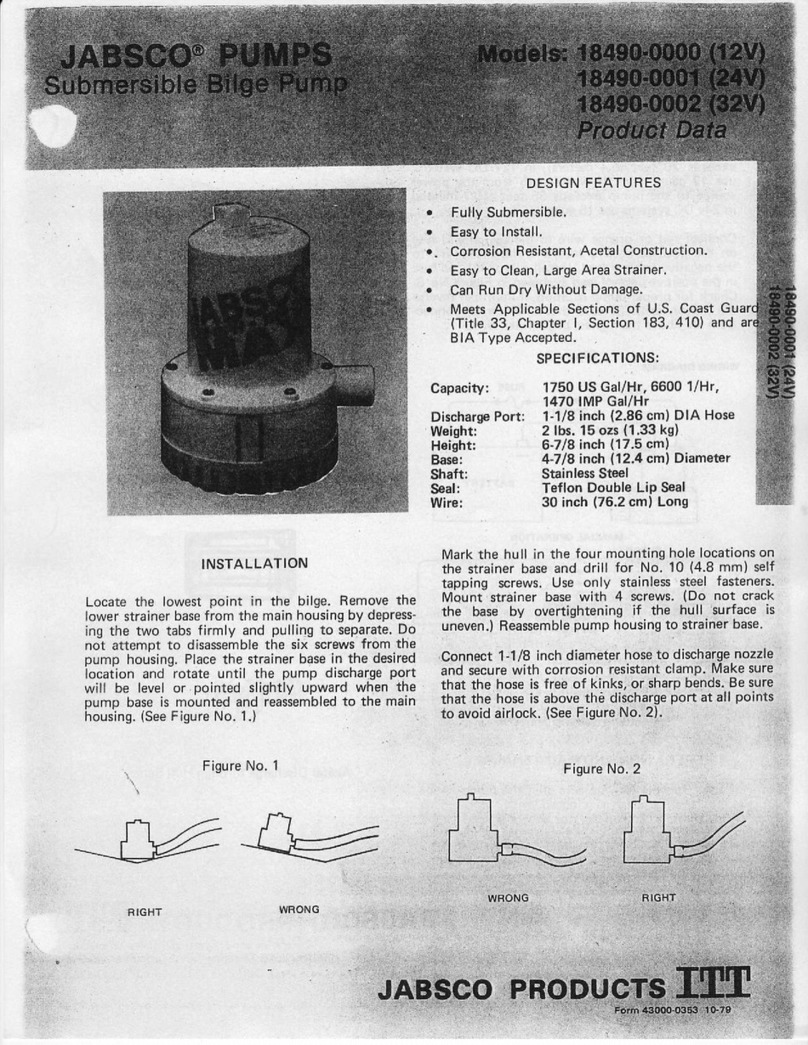

INSTALLATION INSTRUCTIONS:

Jabsco Utility Puppies can be mounted on any flat surface.

Fit the pump in a dry, well ventilated position where there

is full access for service. If installed in a vertical position

the motor must be above the pump head. Use the rubber

grommets provided to minimise vibration, do not

overtighten the mounting screws.

¾” NPT threaded fittings should be used to connect 1” i.d.

suction and discharge hoses. Secure the hose to the

fittings with stainless steel hose clamps. Use spiral

reinforced hose (with a smooth internal bore) that will not

collapse under suction, or rigid or semi rigid pipework

systems. The pipework must be compatible with the liquid

being pumped. Pipe runs should be kept as straight and

short as possible, avoiding rising and dipping over

obstructions. Fit an inlet strainer on the inlet hose to

prevent blockage.

WIRING INSTRUCTIONS

Make all electrical connections in dry locations,

connections in humid environments should be sealed to

prevent corrosion. Protect the circuit with a correctly sized

fuse or circuit breaker in the positive (+) lead as close as

possible to the power source. Select the correct cable size

from the chart below. Inadequate voltage at the motor

terminals when the pump is running (not less than 10%

below rated voltage at full load) due to partially discharged

batteries or insufficient cable size may result in blowing

fuses, failure to start or poor pump performance.

Connect the black motor wire to the negative (-) battery

terminal. The red wire should run via a suitably rated

switch or circuit breaker to the positive (+) battery terminal.

WARNING: If the fuse fails repeatedly do not

fit a heavier fuse or bridge the fuse terminals

with silver paper or metal wire. Failure to

observe this instruction may result in a fire

hazard due to overheating of cables.

WARNING: All marine pumps discharging

overboard must be installed with the over-

board discharge well above both static and

heeled waterlines.