第9页共 10 页

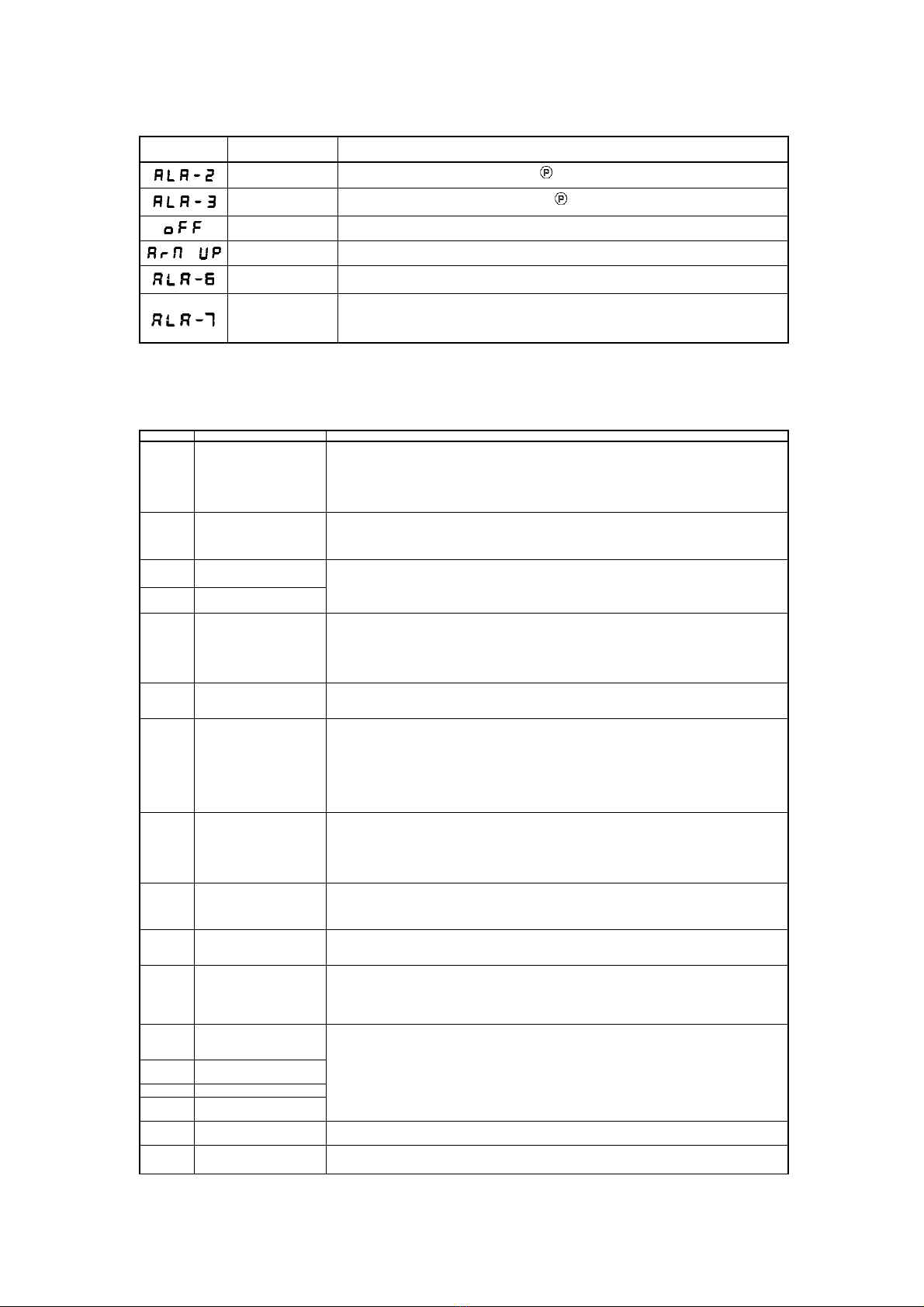

4.3 The warning message

Alarm code Description Corrective

Stitch counter alarm The stitch counter reaches the limit. Press key to cancel the alarm and reset the counter.

Trimming counter

alarm The trimming counter reaches the limit. Press key to cancel the alarm and reset the counter.

Power off alarm Please wait for 30 seconds, then turn on the power switch

Safety switch alarm Adjust the machine to the correct position.

The speed controller

is abnormal

Disconnect the power supply and check whether the line contact of the speed controller is

detached

Stepper motor out of

position Adjust the parameter item P123 to check the installation position of the stepping motor

4.4 Error mode

If the error code appears, please check the following items first:1.Make sure the machine has been connected correctly; 2. Confirm that the

control box match with the machine head. 3. Confirm factory reset is accurate

Error Code Description Solution

Err-01 Arm shaft motor

hardware overcurrent

1. Turn off the system power, and turn it on again after 30 seconds.

2. Please enter P61 to check the initial angle of the arm shaft motor.

3. Check whether the arm shaft motor encoder and electronic control are damaged or in other poor

conditions. If so, replace them in time.

4. If the system still does not work properly after troubleshooting and restart.

Please contact your local service provider or call 4008876858.

Err-03 System undervoltage

Disconnect the power supply of the controller and check whether the input power supply voltage is

lower than 176V. If so, please restart the controller after the voltage returns to normal. If the voltage

returns to normal, it still does not work properly after the controller starts up.

Please contact your local service provider or call 4008876858.

Err-04 Overvoltage during

shutdown

Disconnect the controller power and check whether the input power voltage is higher than 264V. If

so, please restart the controller after the voltage returns to normal. If the voltage returns to normal, it

still does not work properly after the controller starts up.

Please contact your local service provider or call 4008876858.

Err-05 Overvoltage during

operation

Err-06 Electromagnet circuit

failure

1. Turn off the system power, check whether the electromagnet connection is correct and whether

there is any loose or damaged part. If so, replace it in time.

2. Unplug the 14-pin plug on the electric control to confirm whether the electric control is normal. If

the electric control is normal, please check whether the electromagnetic circuits are damaged.

3. If the system still does not work after troubleshooting and restart.

Please contact your local service provider or call 4008876858.

Err-07 Current detection circuit

failure

Turn off the system power, and turn on the power again after 30 seconds to see whether it can work

properly. Try a few times again. If the fault occurs frequently, please contact your local service

provider or call 4008876858.

Err-08 Arm shaft motor stalled

1. Please check whether there is any foreign object wrapped around the machine head, whether

there is any thread residue stuck in the rotating shuttle, and whether the eccentric wheel of the

machine is stuck.

2. Disconnect the power supply of the controller and check whether the input plug of the arm shaft

motor power supply is detached, loose, or damaged.

3. Please enter P61 to check the initial angle of the arm shaft motor.

4. If the system still does not work properly after troubleshooting and restart.

Please contact your local service provider or call 4008876858.

Err-10 Panel communication

failure

1. Please check whether the connection between the operation panel and the electric control is

drops off, loose, or broken.

2. Please check whether the connection cable of the pedal speed controller is drops off, loose, or

damaged.

3. If the system still does not work properly after troubleshooting and restart.

Please contact your local service provider or call 4008876858.

Err-11 Head stop signal failure

1. Check whether the connection between the arm shaft motor encoder and the controller is loose.

2. Replace the arm shaft motor encoder.

3. If the system still does not work properly after troubleshooting and restart.

Please contact your local service provider or call 4008876858.

Err-12 Arm shaft motor initial

angle detection failure

1. Please enter P61 to check the initial angle of the arm shaft motor.

2. Please try 2-3 times again after power off. If it still fails.

Please contact your local service provider or call 4008876858.

Err-13 Arm shaft motor zero

position fault

1. Turn off the power of the system, check whether the arm shaft motor encoder connector is loose,

or drops off. Restore it to normal and restart the system.

2. Replace the arm shaft motor encoder.

3. If the system still does not work properly after troubleshooting and restart.

Please contact your local service provider or call 4008876858.

Err-14

Master control eeprom

components read/write

failure

Turn off the system power, and then turn on the power again after 30 seconds. If the controller still

does not work properly, please contact your local service provider or call 4008876858

Err-15 Arm shaft motor

overspeed protection

Err-16 Arm shaft motor reverse

Err-17 Master control restart

failure

Err-18 Arm shaft motor overload Check whether the arm shaft motor is stalled. If not, please contact your local service provider or call

4008876858.

Err-20 Alarm for oil shortage

every 8 hours

Check whether the oil level of the machine is sufficient. If the problem is still not resolved after filling

up the oil volume, please contact your local service provider or dial 4008876858.