iii

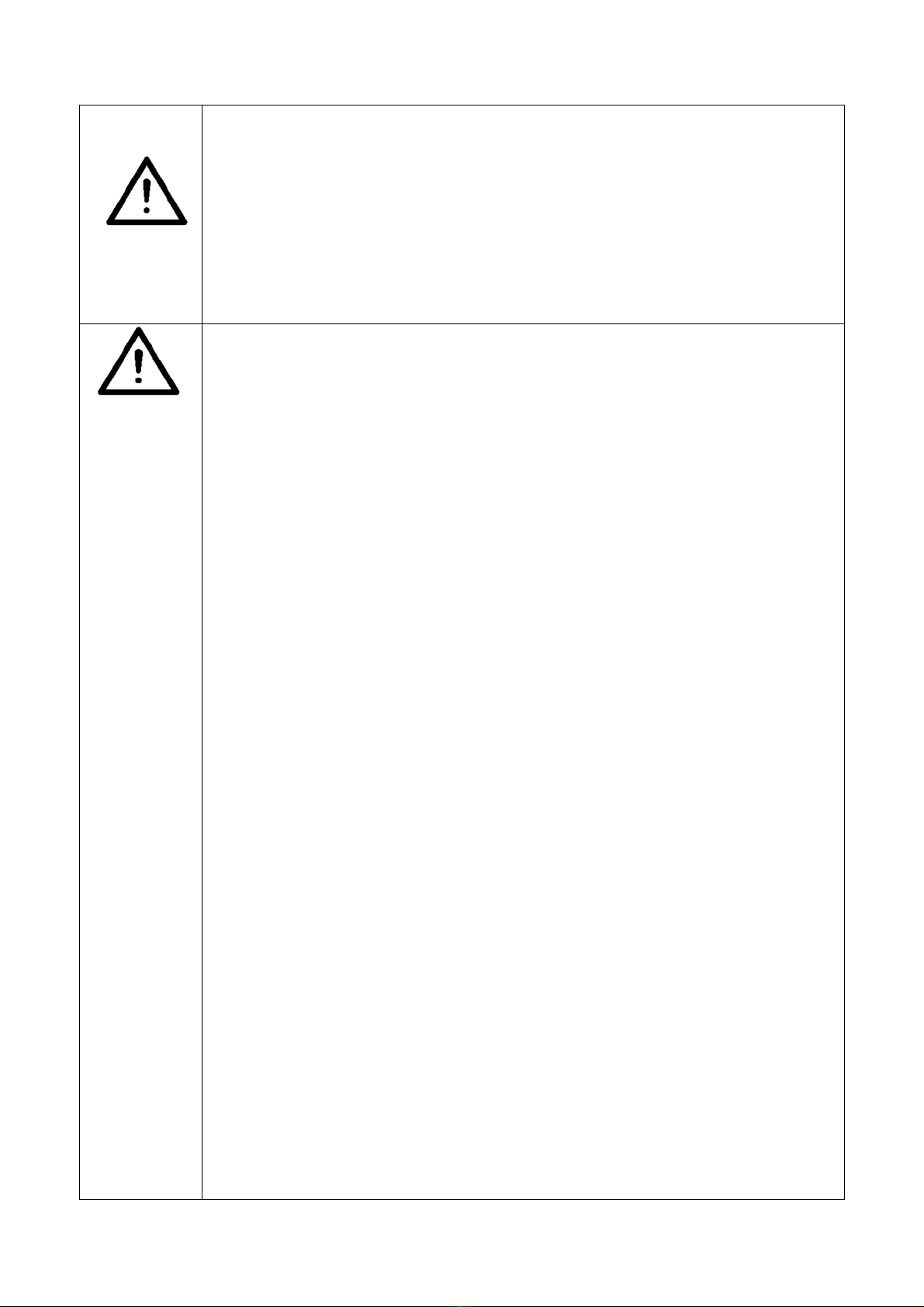

为了安全地使用本缝纫机的注意事项

FOR SAFE OPERATION

危险

DANGER

1. 为了防止触电事故, 打开电源时, 请不要打开马达电气箱盖, 也不要触摸电气箱内

的零件。

To prevent possible accidents due to electric shocks, neither open the cover of

motor electrical box nor touch the component(s) inside the electrical box.

2. 变更图案后, 请确认落针位置。万一压脚超越图案范围, 缝制中有可能机针与压脚相

碰,发生断针的危险。另外, 请确认被设定的压脚和安装到缝纫机的压脚是否一致。

Make sure of the needle entry after changing the pattern. Should the pattern protrude

from the work clamp check, needle interferes with the work clamp check resulting in

the danger of occurrence of needle breakage or the like. In addition, check that the

work clamp check which has been set corresponds to that which has been installed

on the sewing machine.

注意

WARNING

1. 打开(ON) 电源开关后, 操作盘上什么也不显示时, 请关闭(OFF) 电源开关, 然后确

认电源电压和电源规格。

In case nothing is displayed in the operation panel even when the power switch is

turned ON, turn OFF the power switch and check the power voltage and phase.

2. 为了防止造成人身事故, 打开电源时和缝纫机运转途中, 请不要把手指放到挑线杆、

布压脚、布切刀以及机针下面的附近。

To avoid personal injury, never put your fingers under the thread take-up lever, cloth

presser, cloth cutting knife, or needle when you turn the power switch ON or operate

the sewing machine.

3. 为了防止突然的起动造成人身事故, 放倒缝纫机时, 拆卸马达外罩时, 请关掉电源。

To protect against possible accidents due to abrupt startup of the machine, turn OFF

the power switch before tilting the machine head or removing the motor cover.

4. 为了防止卷入机器的人身事故, 缝纫机运转中请不要把手指、头发、衣服靠近马达、

切刀等驱动部分, 也不要把物品放到机器的上面。

To avoid personal injury, never bring your fingers, hair or clothing close to V belt,

cloth cutting knife or motor during operation, and never place anything on any of

these parts.

5. 为了防止对人身的伤害, 请不要在卸下马达外罩、眼睛保护罩等安全装置的状态下运

转缝纫机。

To avoid personal injury, never operate the machine with the motor cover, eye

protection cover, or any other safety devices removed.

6. 为了防止对人身的伤害, 放倒缝纫机时和返回到原来的位置时, 请注意不要夹到手

指

等。

To avoid personal injury, be careful never to allow your fingers to go inside the

machine when tilting or raising the machine head.

7. 为了防止触电和损坏电气零件的事故, 插拔电源插头之前请一定关掉电源开关。

To prevent possible accidents due to electric shocks or damaged electrical

component(s), always turn OFF the power switch before connecting or

disconnecting the power plug.

8. 为了防止损坏电气零件的事故, 打雷时, 请停止操作, 拔下电源插头, 以保证安全。

During thunder and lightning storms, stop your work and disconnect the power from

the outlet to ensure safety and prevent possible accidents due to damaged electrical

component(s).

9. 为了防止损坏电气零件的事故, 从寒冷的地方移动到暖和的地方等时, 容易发生结

露现象, 所以请待水滴完全干燥之后再打开电源。

If the machine is suddenly moved from a cold place to a warm place, dew

condensation may result. If this occurs, be sure to confirm that there are no

potentially dangerous water drops in the machine before turning it on in order to

prevent possible accidents due to damaged electrical component(s).

10. 为了防止损坏电气零件的事故, 停电时, 请一定关掉电源。

In the event of a power failure, be sure to turn OFF the power to the machine to

protect against damaged electrical components.

11. 本装置请在工业用环境下使用。在一般家庭里使用时如果靠近电视机或收音机使用

的话, 有发生接收不良的故障。

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.