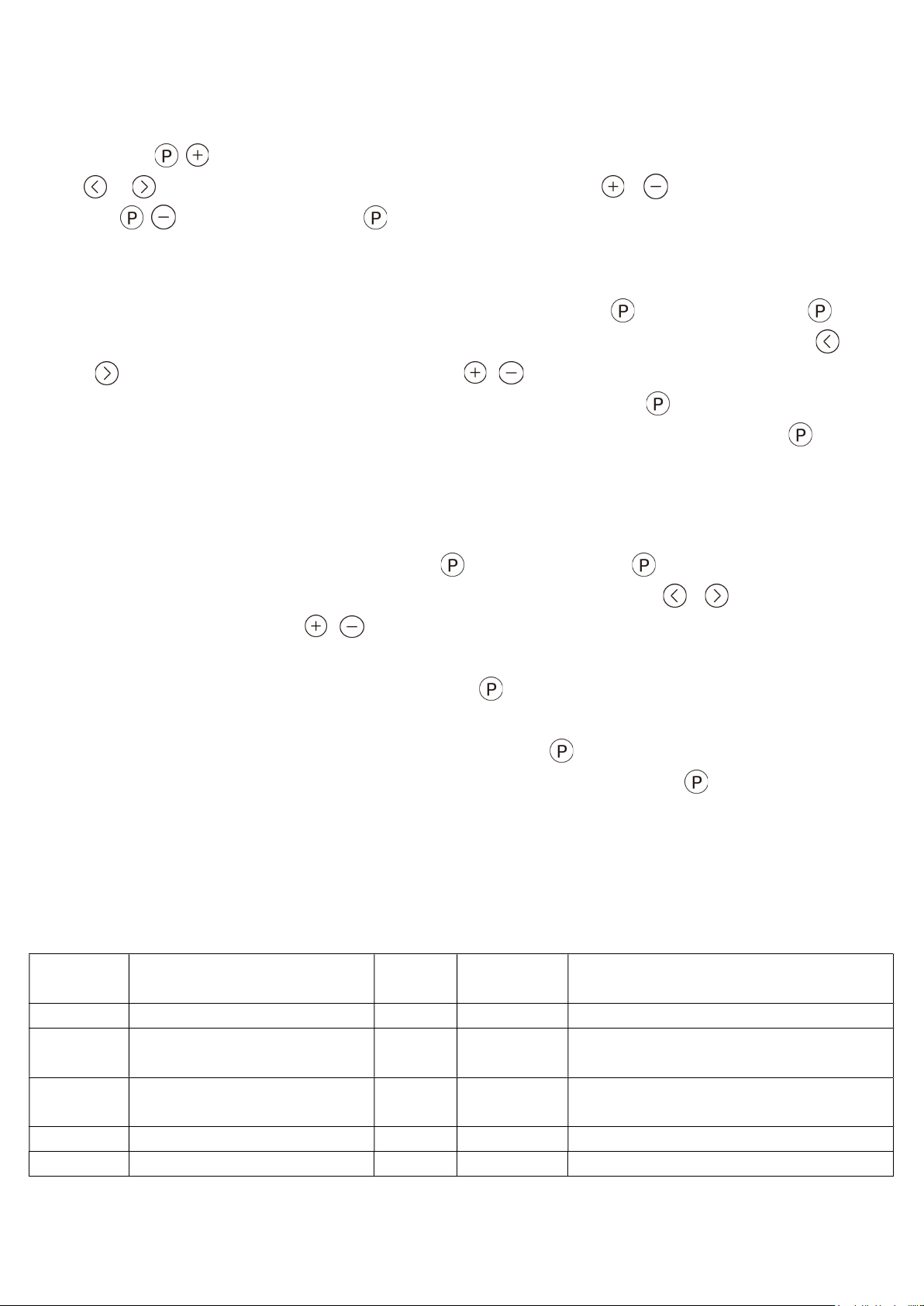

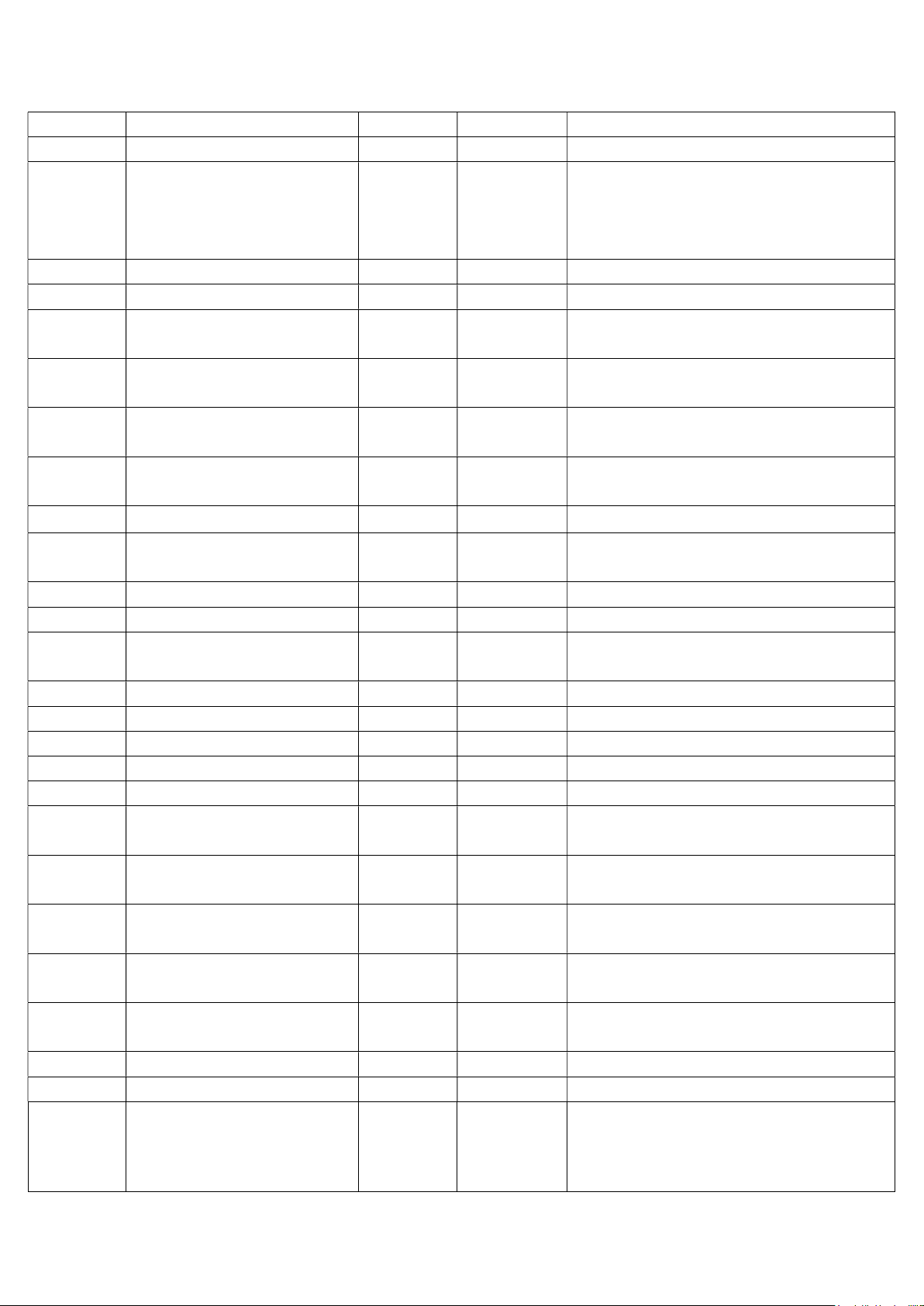

4 / 14

4

Back tacking

The back tacking key is selected for each short press, the cyclical

selection is between the front tacking, the front double tacking and

the closing, and the corresponding LCD screen is lit. Select the

corresponding key to set the number of needles of C and D.

5

Thread clamp/

Auto trigger key

Press this key for short time,ico become lit, so thread clamp is

working now, press again, the turn this function

Long press this key in multi-segment sewing mode to turn on and

off the automatic trigger function

6

Press foot lift key

Press this key for short time, choose or cancel this function. If

choose this function, then will show press foot lift after trimmer

Press this key for long time, choose or cancel this function, if

choose, will show press foot lift on halfway

7

Free

sewing/trimmer

Press for short time, icon become lit, choose free sewing function.

Press for long time, icon become lit, trimmer function turn on, press

again, trimmer function turn off.

8

W sewing/

Multi-segment

Tacking

1、Press this key for short time, icon is lit, so now is W sewing

mode, choose the corresponding key to set A,B,C,D

2、Press the key for long time, icon is lit, means now is Several

Segment Tacking mode, choose corresponding key to set all steps,

and all stitches of each step.

9

Lock stitch

key/Needle

position

section key

Press short time to this key, the lock stitch function will switch to

front lock, rear lock, front and back lock, close; Press long time to

enter needle position function

10

Pattern sewing

key/Presser foot

lifting key

Short press this key to enter the pattern sewing mode, short press

this key in this mode to switch between the pattern sewing interface

and the pattern sewing setting interface

Long press this button to switch the presser foot lifting function

switch, the corresponding icon is on and off, and the icon is on to

indicate that the presser foot lifting function is on

11

Power-on voice

message and

voice on/off key

Without error warning:

1. Short press this key: The power-on voice is disabled. Short press

again to enable the power-on voice.

2. Long press this key: The voice function is disabled. Then, long

press again to enable the voice function.

With error warning: Short press this key to broadcast the error

code solution directly.

12

Parameter mode Enter the parameter function

13

Up key(speed up)

Enter this mode, adjust this key, increase speed