7/8

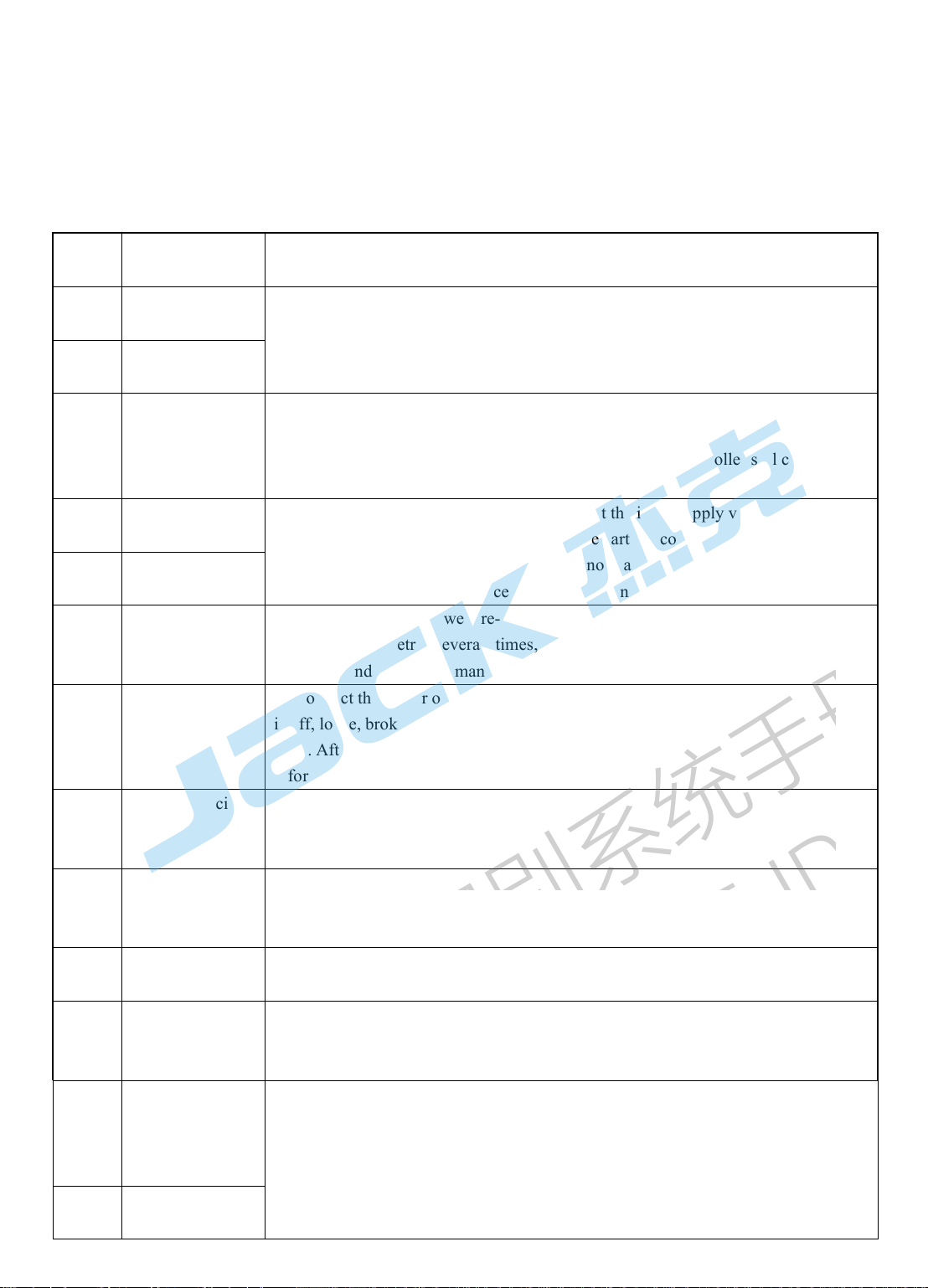

4 Error code

4.1 Error code table

If the system shows error or alarm, please first check the following items:

1. first, confirm if the machine's connection cable is intact; 2. Confirm whether the electronic control

box and the machine is matched or not; 3. Confirm whether the factory reset is accurate or not.

Error

code Code meaning Countermeasure

Err-01 Hardware

overcurrent Turn off the system power, re-connect the power after 30 seconds, if the controller

still can not work, replace the controller and notify the factory.

Err-02 Software

overcurrent

Err-03 System

undervoltage

isconnect the controller power and check if the input supply voltage is low (under

110V). If the supply voltage is low, restart the controller after the voltage has

returned to normal. If the voltage is still normal, start the controller still can not

work properly, please replace the controller and notify the factory.

Err-04 Excessive

shutdown

isconnect the controller power and check that the input supply voltage is high

(above 275V). If the supply voltage is high, restart the controller after the voltage

has returned to normal. If the voltage is still normal, if restart the controller still can

not work properly, please replace the controller and notify the factory.

Err-05 Running over

voltage

Err-07 Current detection

circuit failure

Turn off the system power, re-connected after 30 seconds to observe whether the

normal work. Retry several times, if the fault occurs frequently, replace the

controller and inform the manufacturer.

Err-08 Motor stalled

isconnect the power of the controller, check whether the motor power input plug

is off, loose, broken, whether there is foreign body wrapped around the machine

head. After resetting the system still does not work, replace the controller and

inform the factory.

Err-09

Brake circuit

failure

Turn off the system power, check the power board of white brake resistor connector

is loose or fall off, put it tight and restart the system. If it still does not work, replace

the controller and inform the manufacturer.

Err-10

HMI

communication

failure

Check whether the connection between the control panel and the controller is off,

loosening, breaking, and restarting the system after returning to normal. If it still

does not work, replace the controller and inform the manufacturer.

Err-12 Motor initial angle

detection fault

Please try restart 2-3 times, if still reported failure, please replace the controller and

notify the factory.

Err-13

Motor optical

encoder signal

missing

Turn off the system power, check the motor sensor connector is loose or off, to

return to normal after the restart system. If it still does not work, replace the

controller and inform the manufacturer.

Err-14

EEPROM

Motherboard read

and write

EEPROM fault Turn off the system power, restart the system after 30 seconds, if still can not work,

please replace the controller and notify the factory.

Err-15 Motor overspeed

protection

企业识别系统手册

CORPORATE IDENTITY SYSTEM

GUIDELINES