目录 CONTENTS

目录 CONTENTS .......................................................................................................................... - 1 -

1. 产品规格(SPECIFCATIONS)....................................................................................... - 2 -

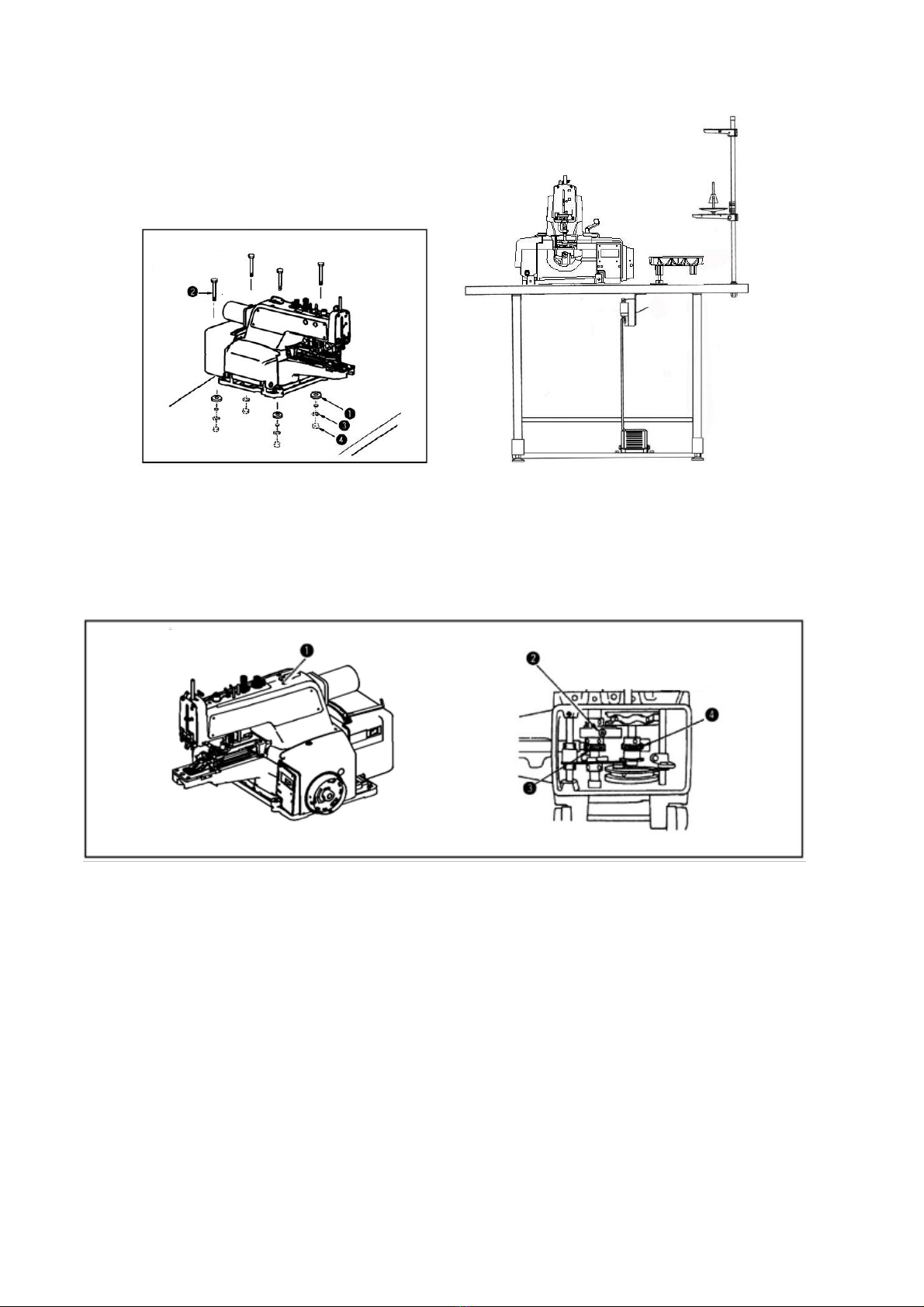

2.机头安装方法(INSTALLATION OF MACHINE HEAD)......................................................... - 3 -

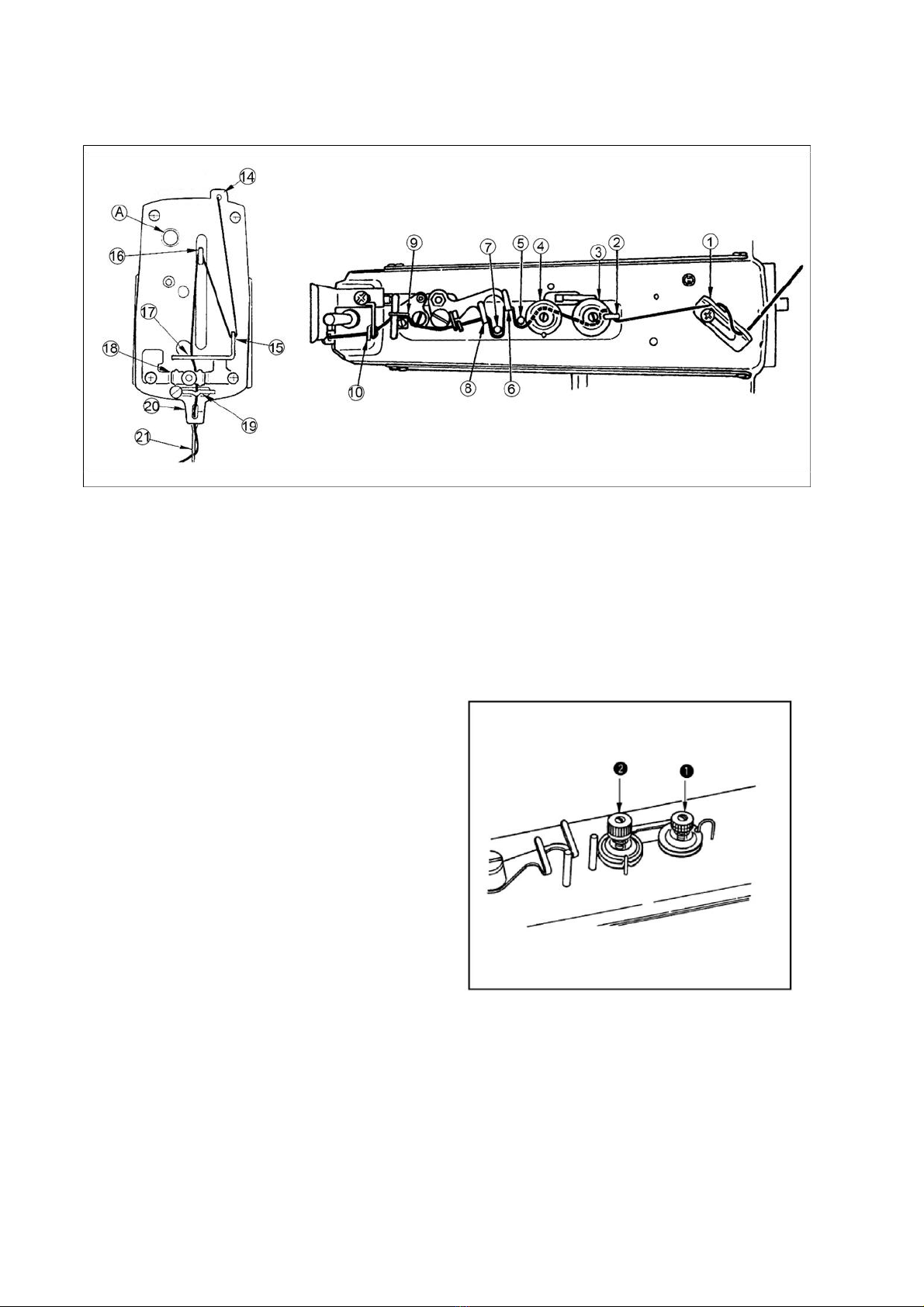

3.加油方法(LUBRICATION)............................................................................................. - 3 -

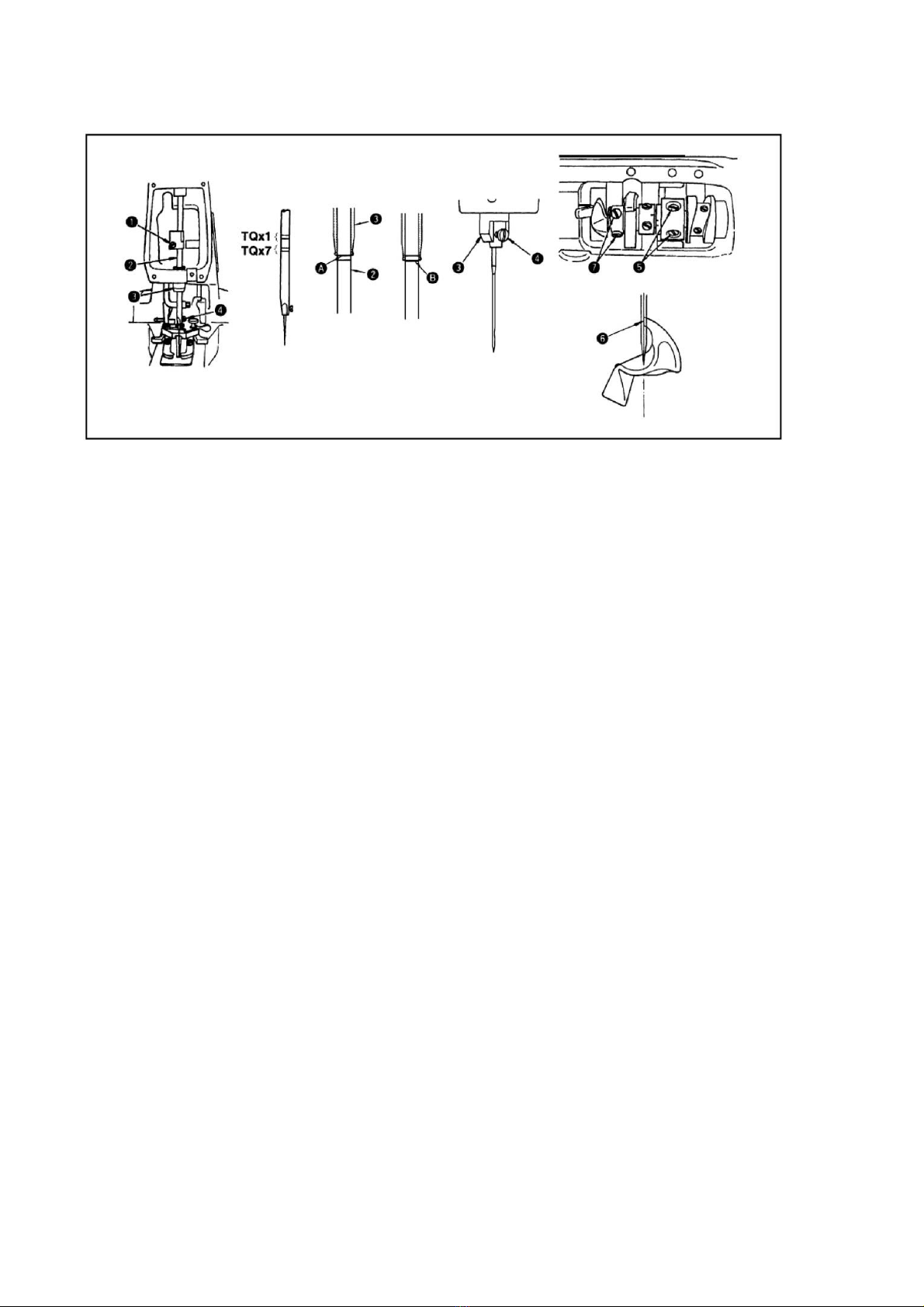

4.机针安装方法 (ATTACHING THE NEEDLE)............................................................. - 4 -

5.针杆罩的安装方法 (ATTACHING THE NEEDLE BAR GUARD)............................ - 4 -

6.纽扣盘的安装方法(ATTACHING THE BUTTON TRAY ASSEMBLY).................. - 4 -

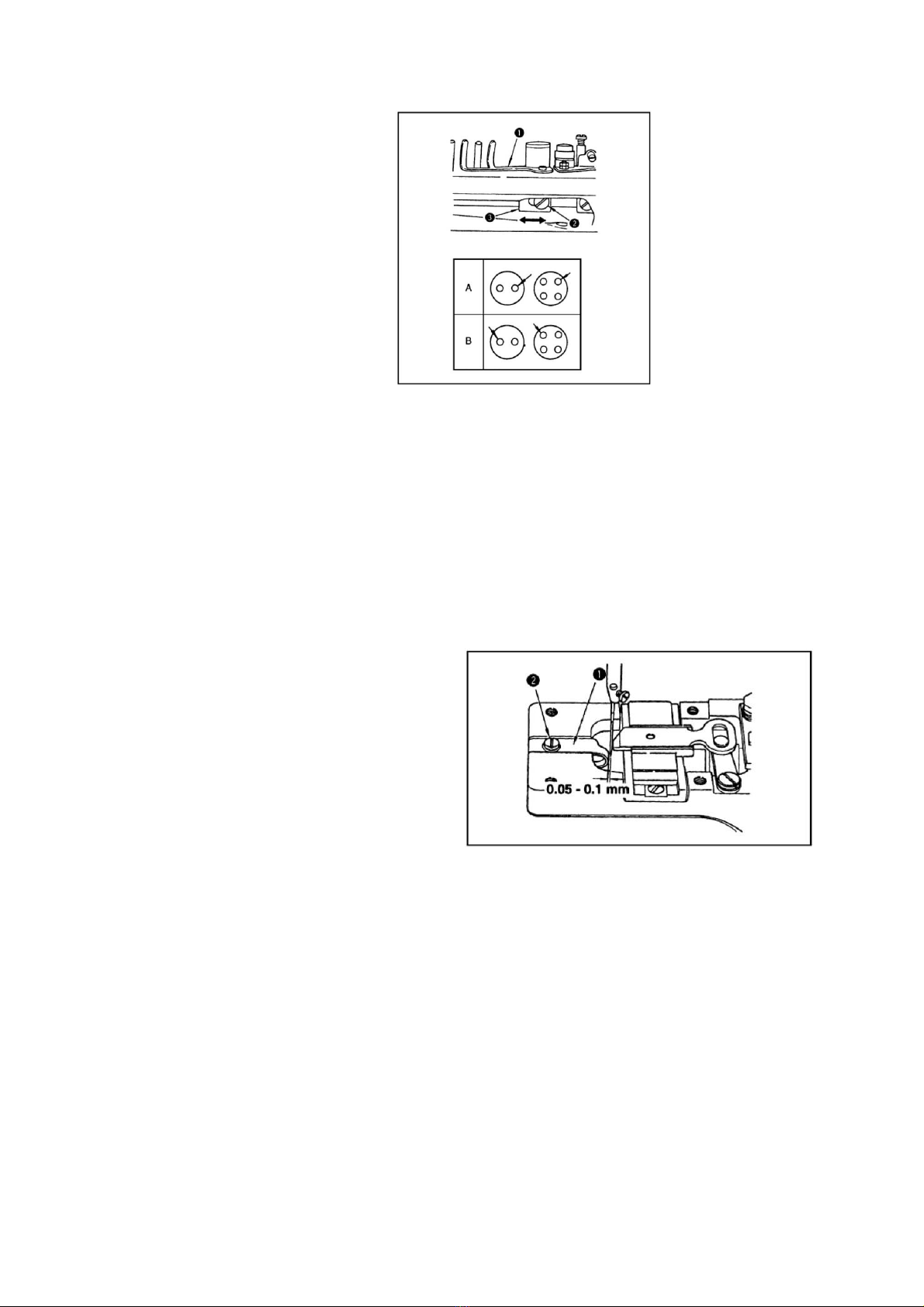

7.上线穿线方法(THREADING THE MACHINE ).......................................................... - 5 -

8.线张力(THREAD TENSION ADJUSTMENT)............................................................ - 5 -

9.线调节杆的调整(ADJUSTMENT OF THE THREAD PULL -OFF LEVER)........... - 6 -

10.针导向器的位置(POSITION OF THE NEEDLE GUIDE )....................................... - 6 -

11.机针和弯针的关系(NEEDLE -TO-LOOPER RELATION)................................................... - 7 -

12.爪扣装置的高度(HEIGHT OF THE BUTTON CLAMP).......................................... - 8 -

13. 拨针器的调整(ADJUSTMENT OF THE NIPPER ).................................................. - 8 -

14. 压脚压力的调节(WORK PRESSING FORCE )....................................................... - 8 -

15. 压脚压力的调节(ADJUSTMENT OF THE BUTTON CLAMP STOP LEVER).. - 9 -

16. 松线同步时间的调整(TIMING OF THREAD TENSION RELEASE).................. - 9 -

17. 切线装置(AUTOMATIC THREAD TRIMMER)................................................... - 10 -

第1章产品接口 ...................................................................................................................... - 12 -

1.1 接口插头连接 ............................................................................................................ - 12 -

1.2 接线与接地(Wiring and grounding ) ..................................................................... - 13 -

第2章操作面板使用说明(Chapter 2 operation panel instructions ).................... - 13 -

2.1 操作面板的显示说明(The operation panel display).............................................. - 13 -

2.2 操作面板各按键功能说明 ........................................................................................ - 14 -

第3章系统参数设置说明 ...................................................................................................... - 16 -

3.1 技术员参数表 .......................................................................................................... - 16 -

3.2 系统员参数表 .......................................................................................................... - 18 -

3.3 监控参数表 .............................................................................................................. - 19 -

3.4 故障代码表 .............................................................................................................. - 20 -

第4章特殊功能操作说明 ...................................................................................................... - 23 -

4.1 上停针位调整........................................................................................................... - 23 -

4.2 一键恢复机头厂家参数值 ...................................................................................... - 24 -

4.3 自动测试 .................................................................................................................. - 24 -

零件样本................................................................................................................................... - 25 -