6

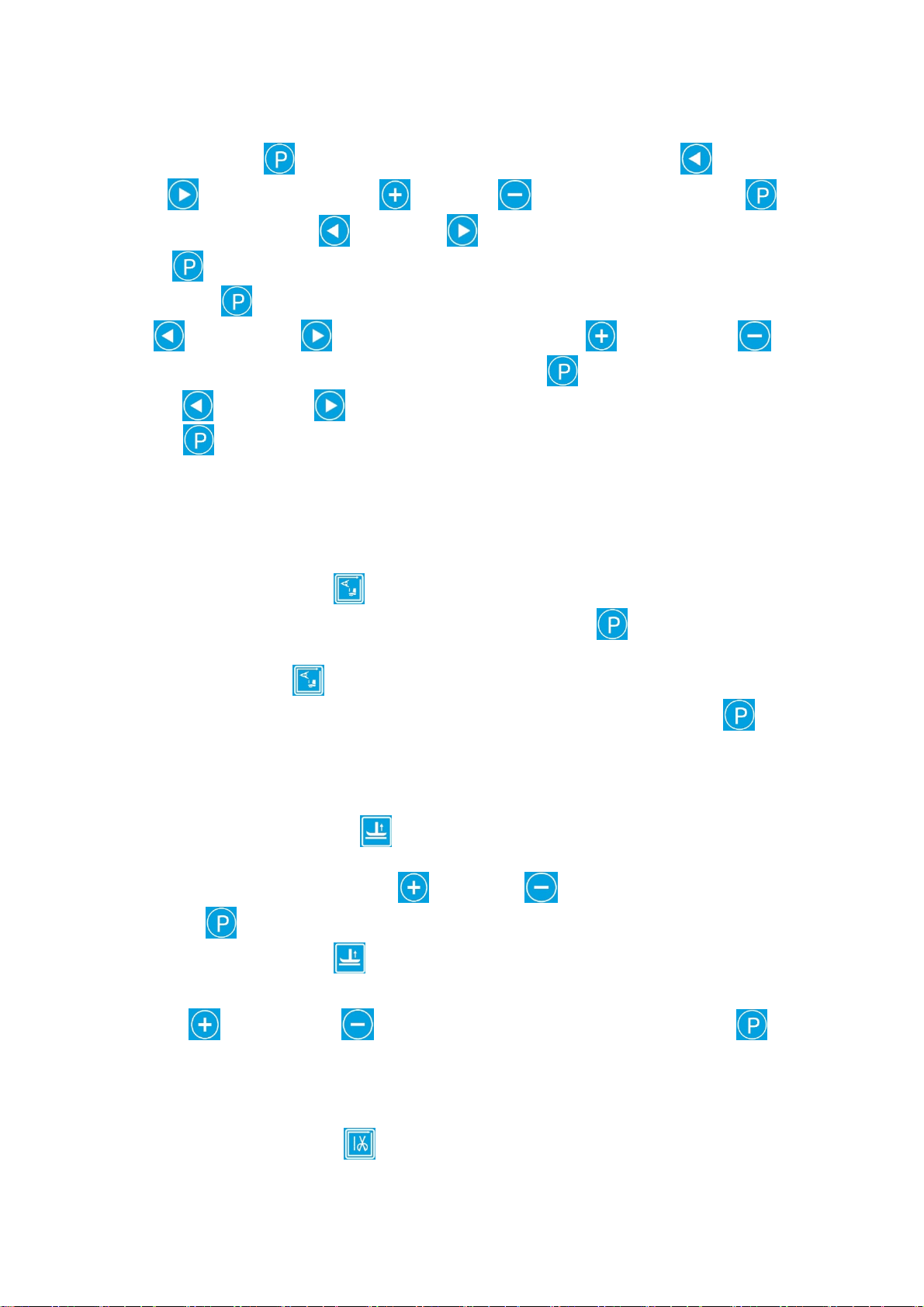

press the right button()for H, S and A switching, press the P key for saving, at this time, the sensor voltage

value will be automatically calibrated again. Showing OK indicates successful selection.

Exit mode: 1.Automatically exit after successful/unsuccessful handover

2.Automatically return to standby interface for key-less operation in 5s

2.15 传感器自动校准 Sensor automatic calibration

长按 P键( )+语音键( )约 1.5 秒便开始传感器自动校准,校准结束后显示

OK 则说明识别成功,否则识别失败。

注:

1、第四传感器使能时(U22=1),P67 以第四传感器电压值进行设定,否则以第二传

感器进行设定;

2、自动校准时,如果某一传感器未使能,则该传感器不进行自动校准且保持默认值不

变;

3、当面料类型改变或第四传感器使能状态改变时,会自动进行传感器自动校准。

Press P button( )+voice button( )for about 1.5 seconds to start the automatic sensor calibration,

and display OK after calibration indicates that the recognition is successful, otherwise the recognition will fail.

1. When the fourth sensor is enabled (U22 = 1), P67 is set by the voltage value of the fourth sensor, otherwise

it is set by the second sensor.

2. In automatic calibration, if a sensor is not enabled, the sensor does not automatically calibrate and keeps

the default value unchanged.

3. When the fabric type changes or the fourth sensor enabled state changes, the sensor will be automatically

calibrated.

2.16 厚料电压阈值设定 Thick material voltage threshold setting

长按抬压脚键( )约 1.5 秒进入厚料电压阈值设定界面,显示压脚高度电压值,调

整压脚高度(布料厚度),长按 P键保存当前显示值到 U15 参数(此数值即为厚料判断阈

值),成功显示 OK 且有语音提示“厚料标准设定成功”,回到待机界面;失败显示 Er。

识别过程中按 P键( )自动退出。

注:当保存的值大于基值-50 或小于 U16 时,会导致保存失败

基值重新设定方法:将 PA2 更改为 1,确保压脚下无布料后,长按抬压脚键( )约

1.5 秒进入厚料电压阈值设定界面,系统自动保存当前值为基值。

Press the presser foot lifter( ) for about 1.5 seconds to enter the thick material voltage threshold setting

interface, display the presser foot height voltage value, adjust the presser foot height (cloth thickness),

and press the P key to save the current display value to the U15 parameter (this value is the thickness judgment

threshold). The OK is successfully displayed and the voice prompt "the thick material standard setting is

successful" is returned. Standby interface; Failure display Er. Press P button()to exit automatically during

recognition.

Note: When the saved value is greater than the base value - 50 or less than U16, the saved value will fail.

Based value reset method: Change PA2 to 1, ensure that no cloth under the presser foot, press the presser foot

button()for about 1.5 seconds to enter the thick material voltage threshold setting interface, and the system

automatically saves the current value as the base value.

2.17 短线头面料设置 Short thread fabric setting

短按短线头键( ),即可进行短线头面料选择;连续按下此键时,模式循环如以下

几种:针织模式 K、梭织模式 W、大针距模式 L。设置完后按 P键( )进行确认保存,

5S 无按键则不保存退到待机界面。

面料选择更改时,针距 U25 参数会自动关联为对应的默认值。