2

(3)基本操作..................................................................................................................................................14

Basic operation.................................................................................................................................................14

2.基本画面的说明.........................................................................................................................16

EXPLANATION OF THE BASIC SCREEN..............................................................................16

3.计数器的使用.............................................................................................................................18

USING THE COUNTER...............................................................................................................18

(1)计数器的设定方法..................................................................................................................................18

Setting procedure of the counter.......................................................................................................................18

(2)计数的解除方法......................................................................................................................................20

Releasing procedure of count-up .....................................................................................................................20

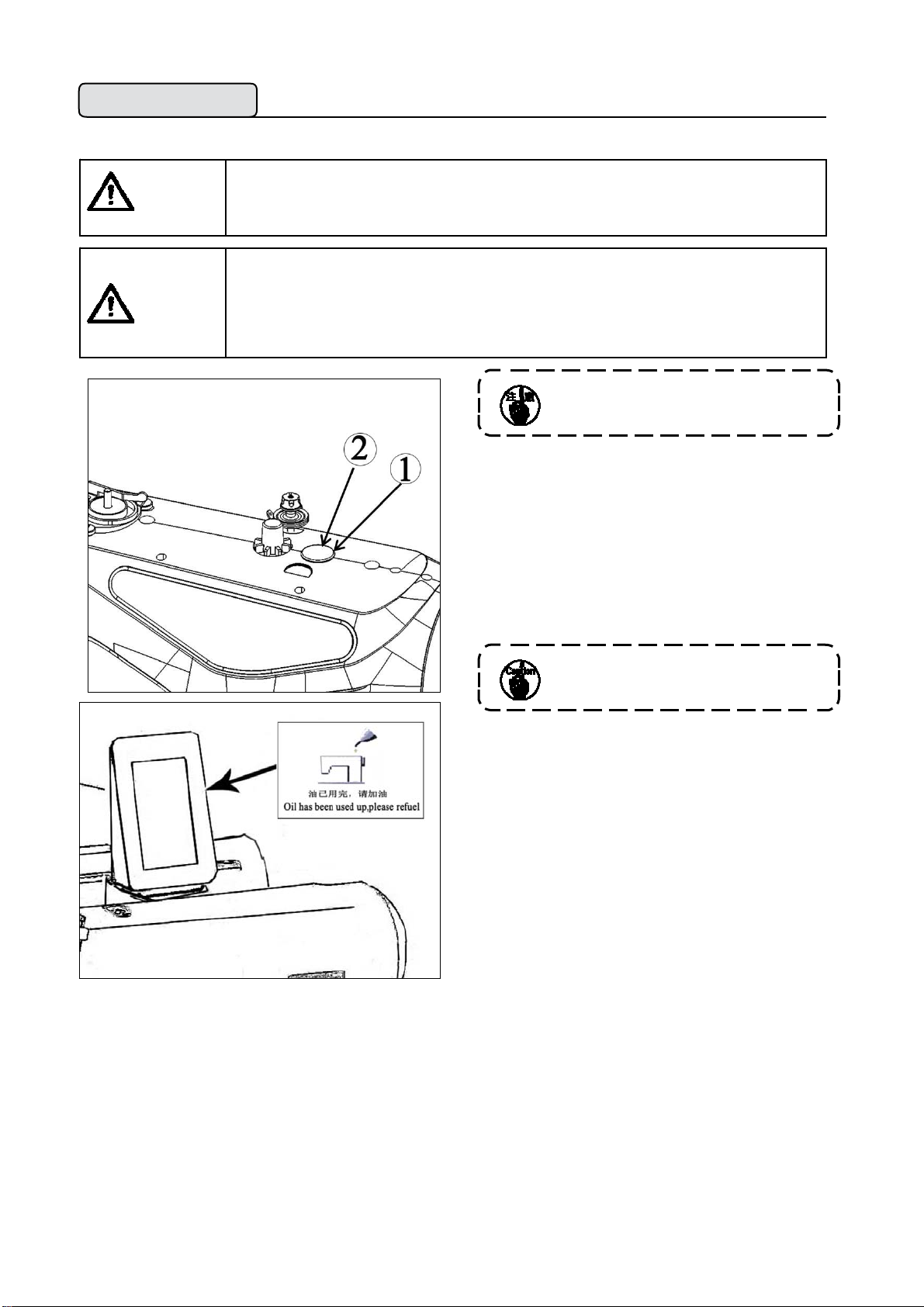

4.底线余量计数器.........................................................................................................................21

USING THE BOBBIN THREAD AMOUNT ADJUSTMENT COUNTER ............................. 21

(1)底线余量计数器的设定方法 ..................................................................................................................21

Setting procedure of the bobbin thread remaining amount adjustment counter.............................................21

(2)解除底线余量调整计数器的计数的方法 ..............................................................................................22

Releasing procedure of the bobbin thread remaining amount detection count-up ...........................................22

5.缝制图案的使用.........................................................................................................................23

USING THE SEWING PATTERN................................................................................................23

(1)选择图案..................................................................................................................................................23

Performing the selection of pattern...................................................................................................................23

(2)编制新图案..............................................................................................................................................24

Performing the new creation of pattern ............................................................................................................24

(3)复制图案..................................................................................................................................................25

Copying the pattern ..........................................................................................................................................25

(4)删除图案..................................................................................................................................................27

Erasing the pattern............................................................................................................................................27

6.变更缝制数据.............................................................................................................................28

CHANGING THE SEWING DATA...............................................................................................28

(1)缝制数据的变更方法..............................................................................................................................28

Changing procedure of the sewing data .........................................................................................................28

(2)缝制数据一览..........................................................................................................................................29

Sewing data list ................................................................................................................................................30

7.变更存储器开关数据.................................................................................................................35

CHANGING THE MEMORY SWITCH DATA ............................................................................35

(1)存储器开关数据的变更方法 ..................................................................................................................35

Changing procedure of the memory switch data............................................................................................35

(2)存储器开关数据一览..............................................................................................................................36

Memory switch data list ...................................................................................................................................37

(3)断线报警..................................................................................................................................................38

Thread breakage alarm .....................................................................................................................................38

8.设定选购项.................................................................................................................................39

PERFORMING OPTIONALSETTING.......................................................................................39

(1)选购项设定的变更方法..........................................................................................................................39

Changing procedure of the optional setting....................................................................................................39

(2)设定选购品一览......................................................................................................................................40

Optional setting list...........................................................................................................................................40

9.管理数据输入画面.....................................................................................................................41

CUSTOMIZING THE DATA INPUT SCREEN..........................................................................41

10.设定缝制画面的管理 ..............................................................................................................42

PERFORMING THE CUSTOMIZING SETTING OF THE SEWING SCREEN................... 42

11.测试 ..........................................................................................................................................43

TEST ...............................................................................................................................................43

(1)测试方法..................................................................................................................................................43

Test method ......................................................................................................................................................43

(2)显示输入/输出端口一览表.....................................................................................................................47

Display the input/output port list......................................................................................................................47

12.使用信息方法 ..........................................................................................................................50