8 / 8

Note: if the error alarm cannot be removed according to the advice, please contact the

manufacturer in time.

If the above problems cannot be solved, please contact the

maintenance personnel.

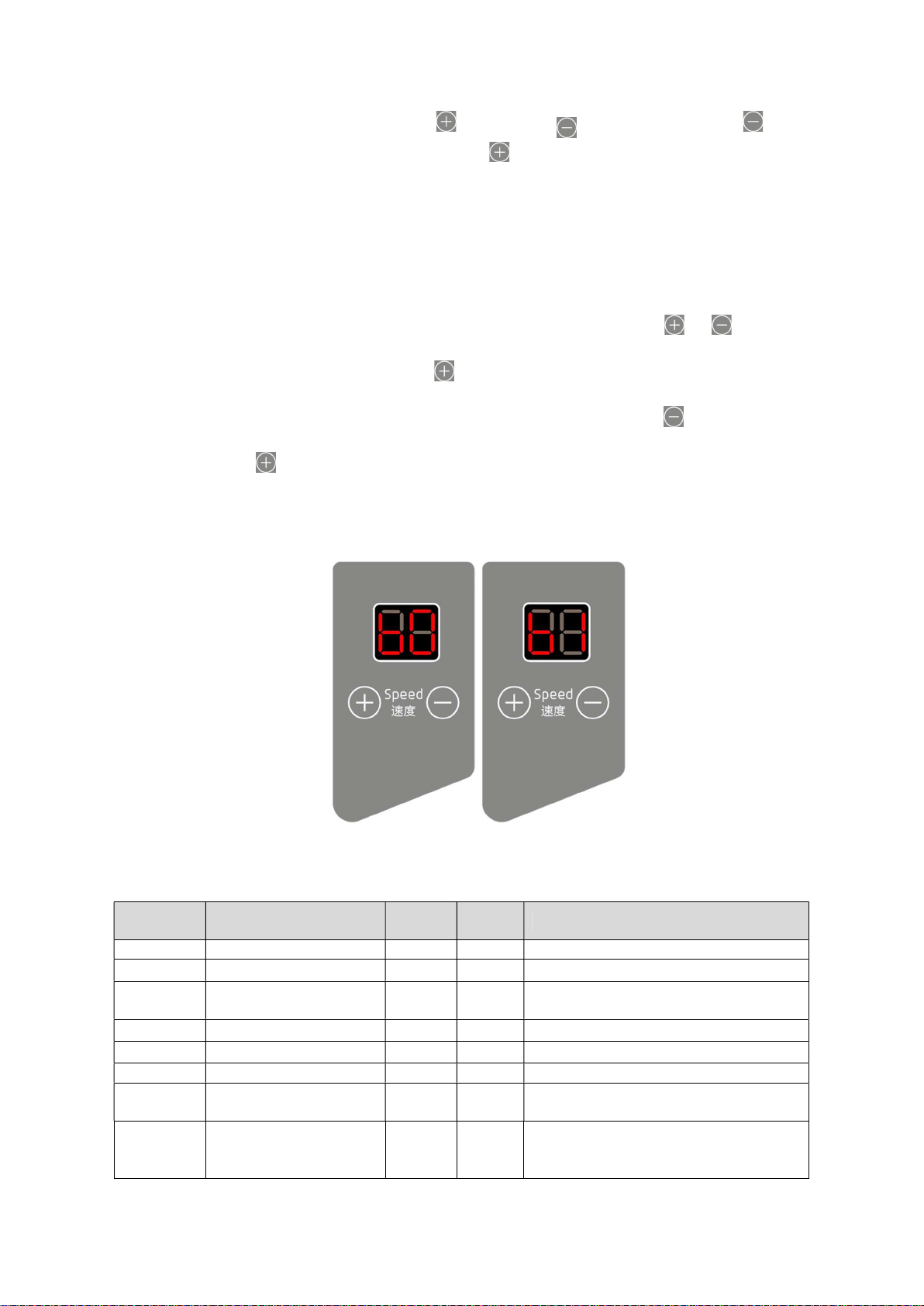

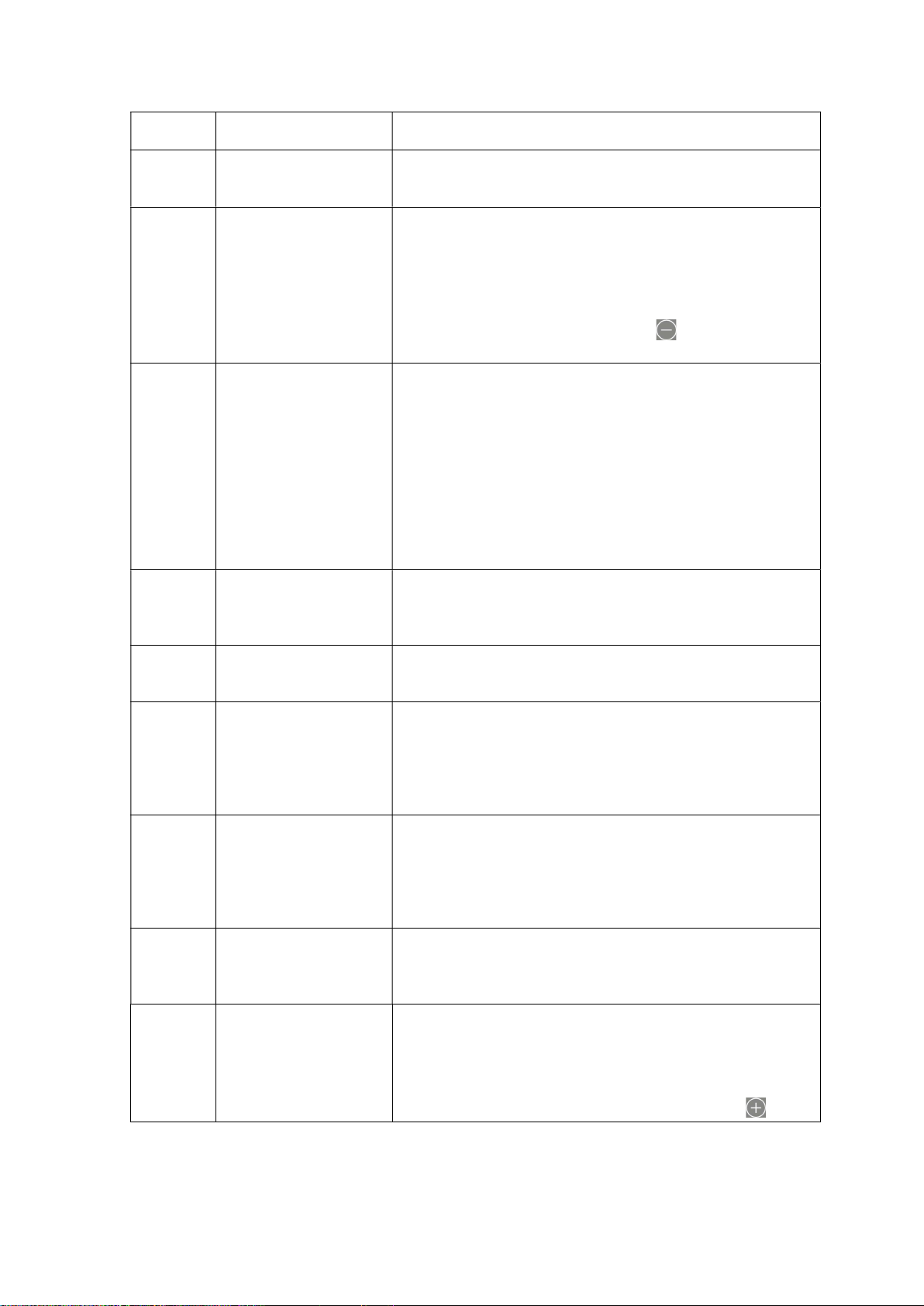

E4 Abnormal motor Hall

signal

Please check whether the motor encoder plug connection is

reliable, whether the encoder signal wire is broken, and

whether the pin exits or deforms.

E5 Abnormal locator signal

Please turn the hand wheel. If the alarm cannot be eliminated,

turn off the power and power on again. If the alarm cannot be

eliminated, please check whether the encoder / positioner plug

connection is reliable;

Abnormal Hall of motor positioner;

(if the positioner is damaged or the positioning function is not

required, when E5 is reported, press for 3S to close the

needle stop function).

E6 Abnormal speed

controller

If E6 alarm is flashing, please check if the speed controller's

type is match with the b parameter (default matching with the

computerized lockstitch machine type),and adjust the b

parameter to match with the current speed controller.

If E6 alarm is always on, please check whether the speed

controller is inserted and whether the plug-in / pin is loose or

falls off;

If the alarm cannot be eliminated, replace the governor; If the

alarm still cannot be eliminated, the signal of the control box

speed controller may be abnormal. Please contact the

maintenance personnel.

E7 Head safety switch

alarm

When the head safety switch is turned on, this alarm will

appear when the machine head dumps; Turn off the safety

switch or restore the head position. If the alarm cannot be

eliminated, please contact the maintenance personnel

EA Software over current

Please turn off the power and power on again. If the alarm

cannot be eliminated, please contact the maintenance

personnel.

Eb System overvoltage

Turn off the power supply immediately and check whether the

power supply voltage exceeds 294v (220V control box) / 147v

(110V control box). If so, please adjust the power supply

voltage to the rated voltage before starting the machine (220V

control box rated voltage: 220V, 110V control box rated

voltage: 110V).

EC System undervoltage

Immediately cut off the power supply and check whether the

power supply voltage is lower than 110V (220V control box) /

55v (110V control box). If so, please adjust the power supply

voltage to the rated voltage before starting the machine (220V

control box rated voltage: 220V, 110V control box rated

voltage: 110V).

EJ Current detection circuit

fault

Please check whether the circuit board is clean;

Please check whether the power supply voltage is normal;

Please wait for the power to be turned on / reset again (please

carefully check the functions of the power board).

EZ Complementary stitch

button failure

Please check whether the complementary stitch button of the

machine head can be turn on and off normally. If it keep in off,

please replace the button of the machine head.

(the alarm will automatically turn off the complementary stitch

function, but will not affect the motor operation. The alarm

will be cleared automatically after 30s or by pressing )