Mechanical adjustments

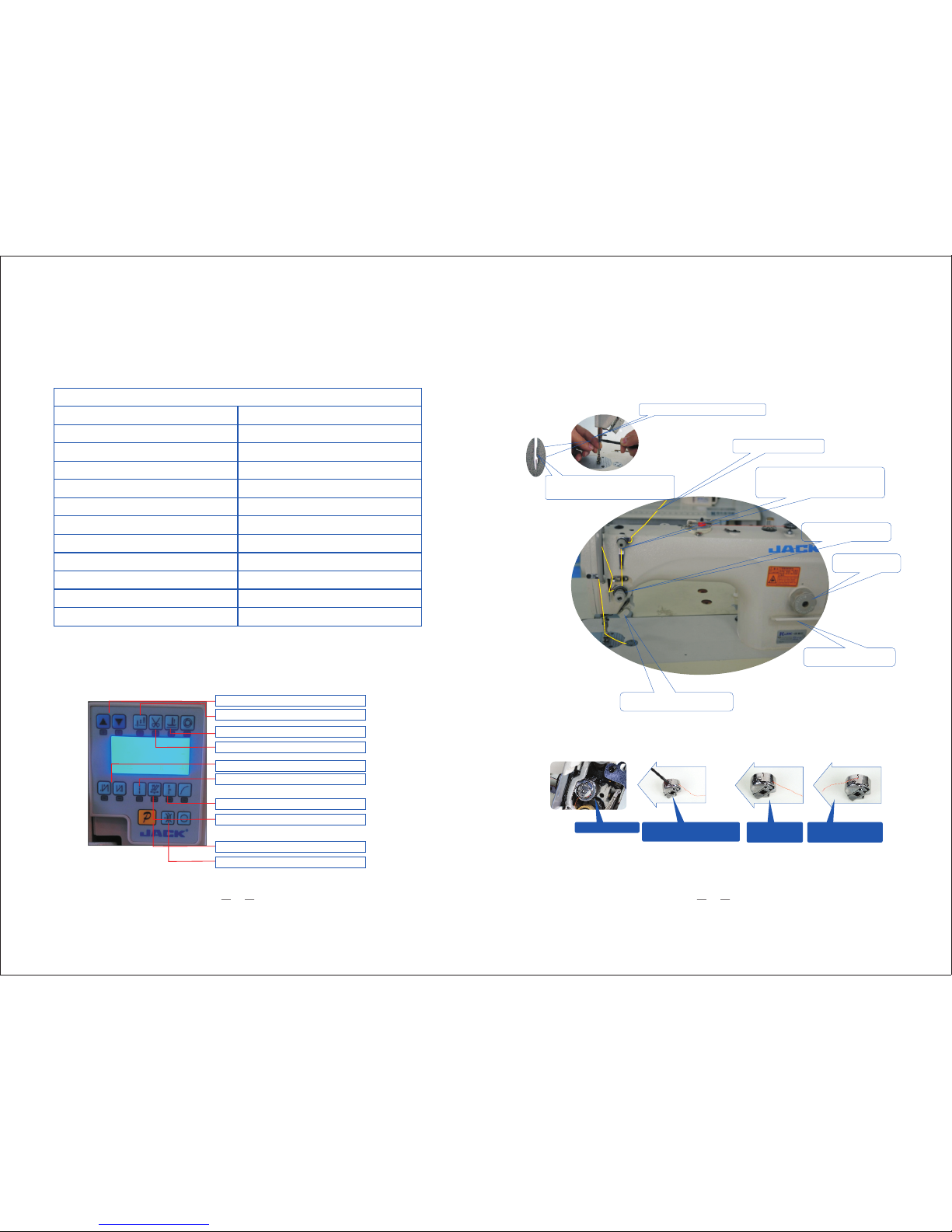

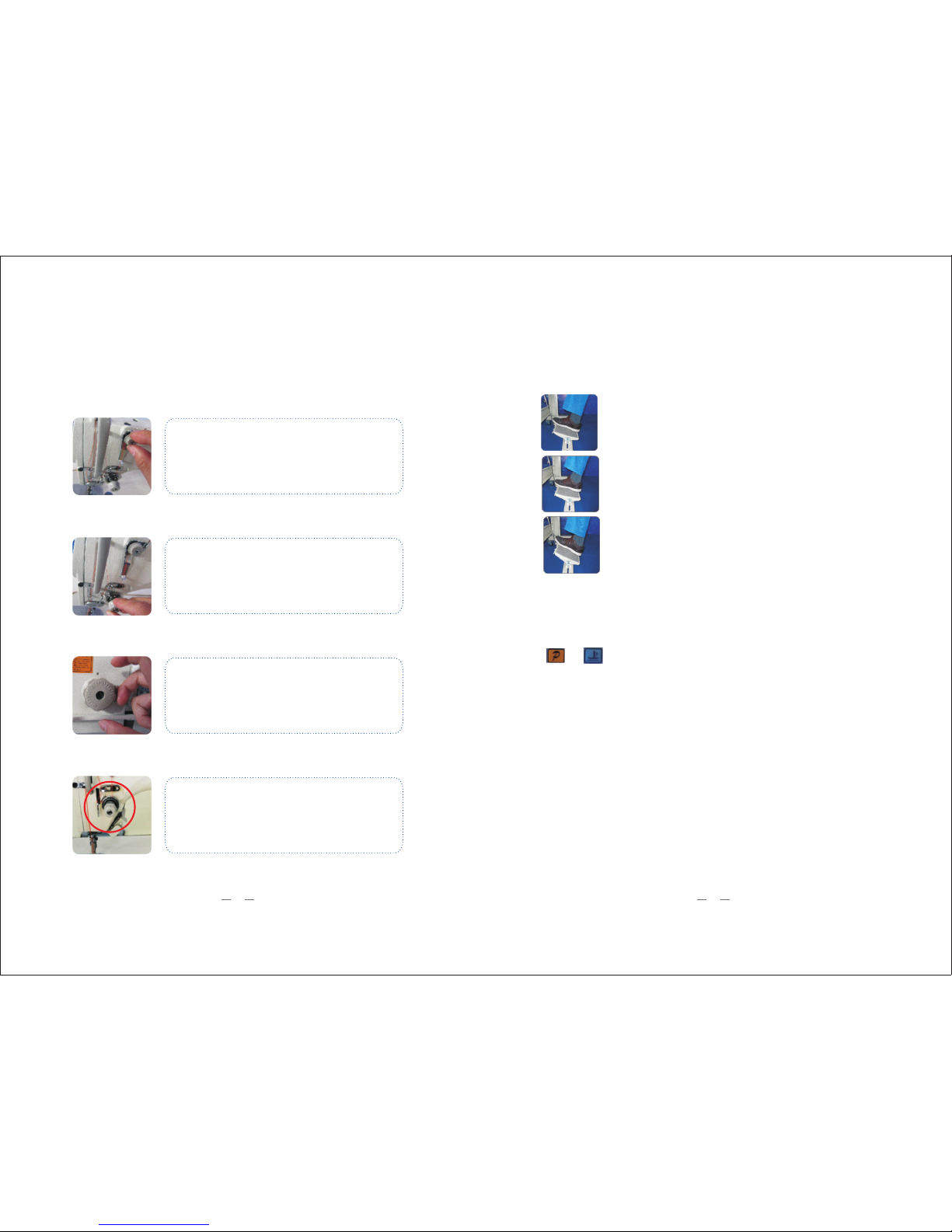

The first tension device adjustment

Control the length on the needle after automatic trimming

and the thread length around 4-4.5 cm is the best. Adjusting

the knob in clockwise way, thread will be short; otherwise, it

will be long.

The main tension device adjustment

Control the tension of thread during sewing. Adjusting the

knob in clockwise way, the tension will be bigger; otherwise,

it will be smaller.If the under-thread loose, the tension

should be adjusted stronger, but too stronger would cause

upper-thread be cut easily

Needle gauge adjustment

The left hand holds the backstitch wrench, with the middle

finger back from the lock to the needle, with the thumb and

index finger rotating needle gauge plate. The gage will be

smaller when turning in clockwise way and will be bigger

when turning in anti-clockwise way.

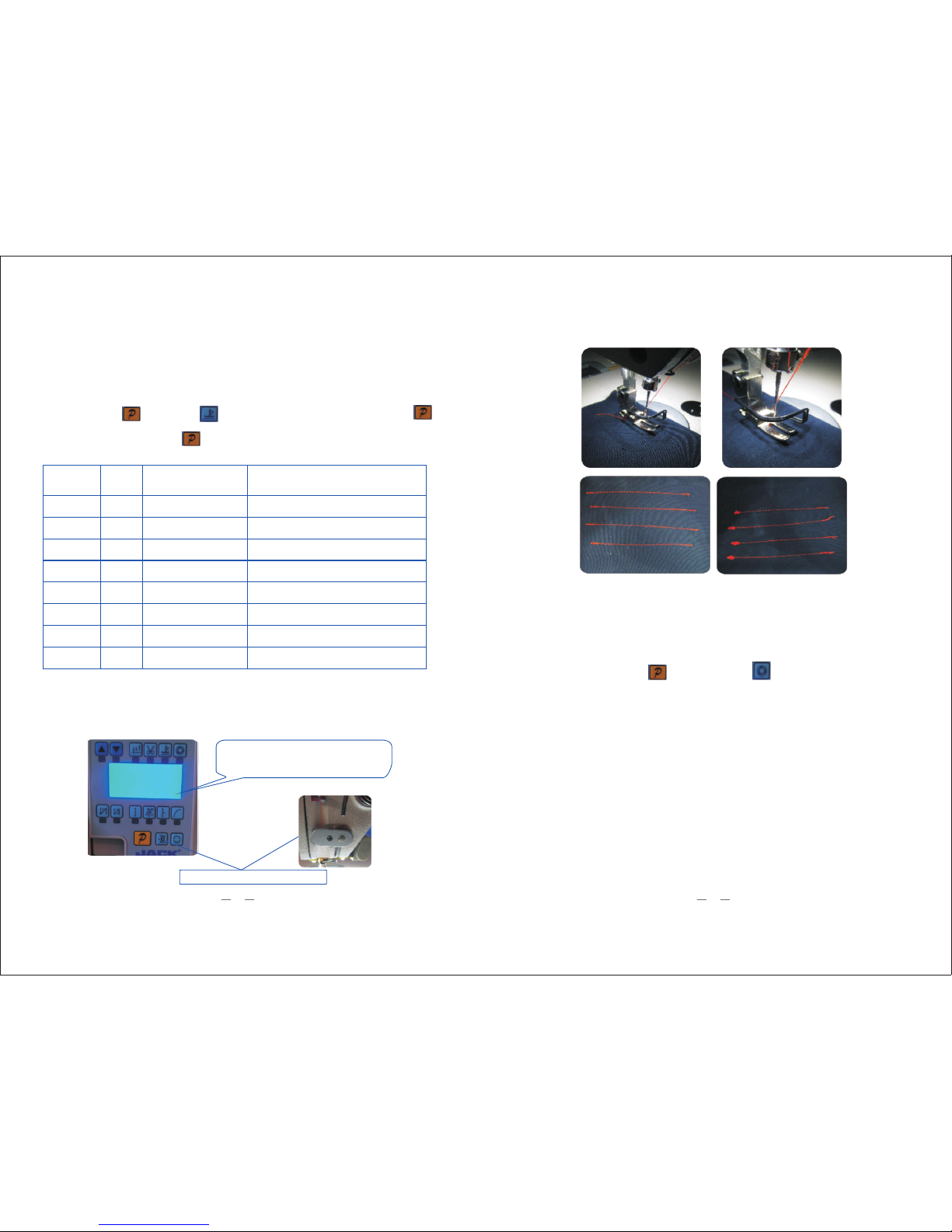

Reverse-sewing button Operation

During sewing, keep pressing the reverse-sewing button , the

machine will be in reverse-sewing state; otherwise, the

machine will be in sewing state.

Press and together to enter technician mode, the pedal control mode can be changed

by adjusting the following parameter:

P30: Pedal Curve mode setup (0:Auto Calculated liner Curve; 1:Two segment liner Curve;

2:Arithmetic Curve; 3:S curve)

P34: Pedal trimming position set (the value is not higher than the parameter [35]);

when adjust P34, need to adjust the value of P35 closer to the value of P36, that’s the sensitivity of

trimming

P35: Press foot lifting (the value is between[34]and[36].)

P36: Pedal back mid position (the value is between[35]and[37] .)

P37: Pedal step upon running position (the value is between[36]and[38]) , if want the machine

to response faster, need to turn down the value of P37, but the value should be higher than P36

P38: Pedal low speed running position(the value is between[37]and[39])

P39: Pedal simulation the largest of value (the value is not lower than the parameter [ 38])

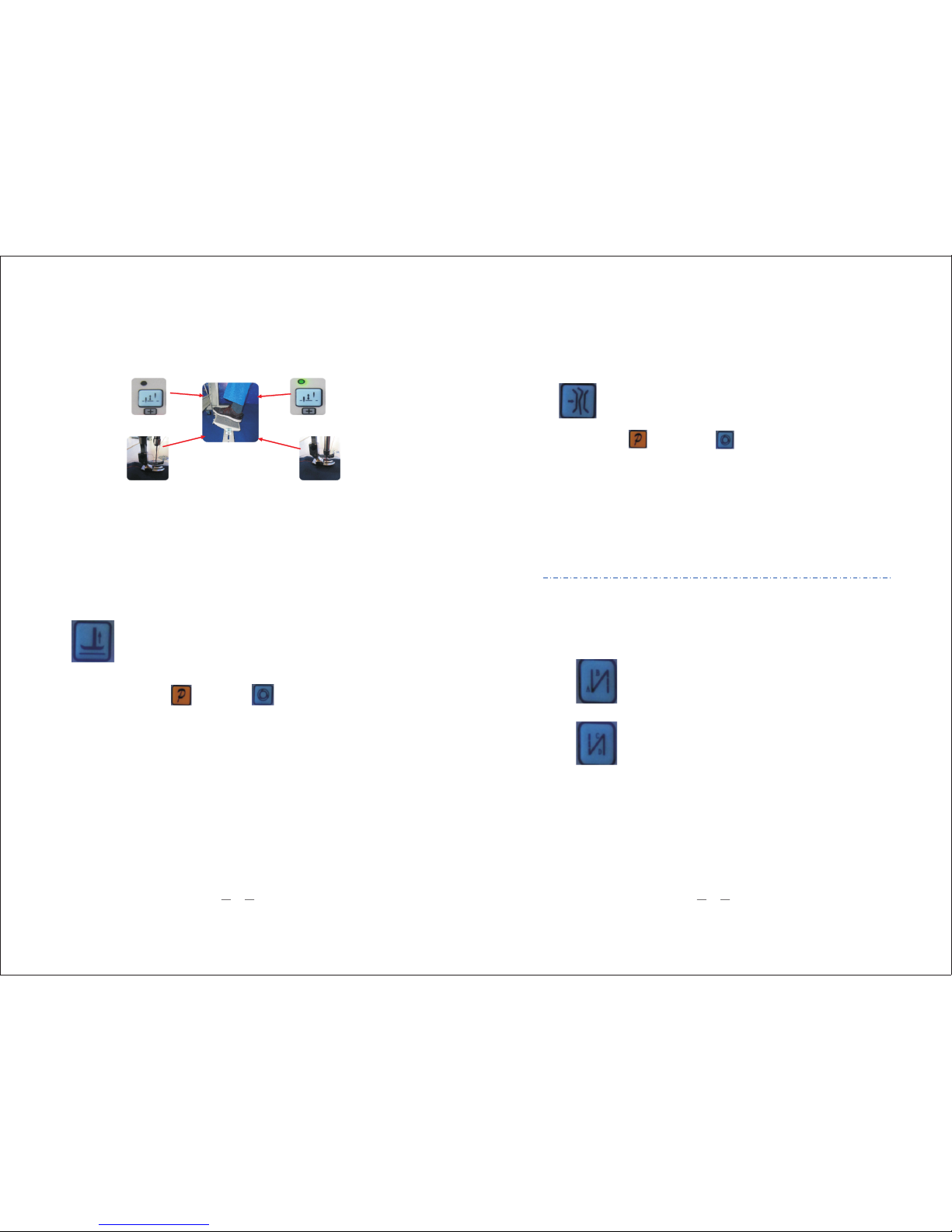

Turn on the power, machine will be up needle position ,the pedal will be as

original state

Step forward to run:

When powered on, the speed will change as the pedal stepped deeper, the

deeper the pedal stepped ,the higher the speed will be.

Step backward to trim and stop:

After sewing, step the rear of pedal, machine will trim and stop. If there is

presser foot lifter accessories, presser foot will lift when stepping backward

further .

Instruction of Pedal Control

Original state

45