v

Փ⫼䇈ᯢⳂᔩ

0$18$/%22.&217(176

ǃ᪡䇈ᯢĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

,16758&7,216

ǃ⫼᠋খ᭄ᡔᴃ᭄ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

86(53$5$0(7(57(&+1,&,$13$5$0(7(5

ǃ䫭䇃ҷⷕ㸼ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

(5525&2'(67$%/(

ǃッষ⼎ᛣĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

32576&+(0$7,&',$*5$0

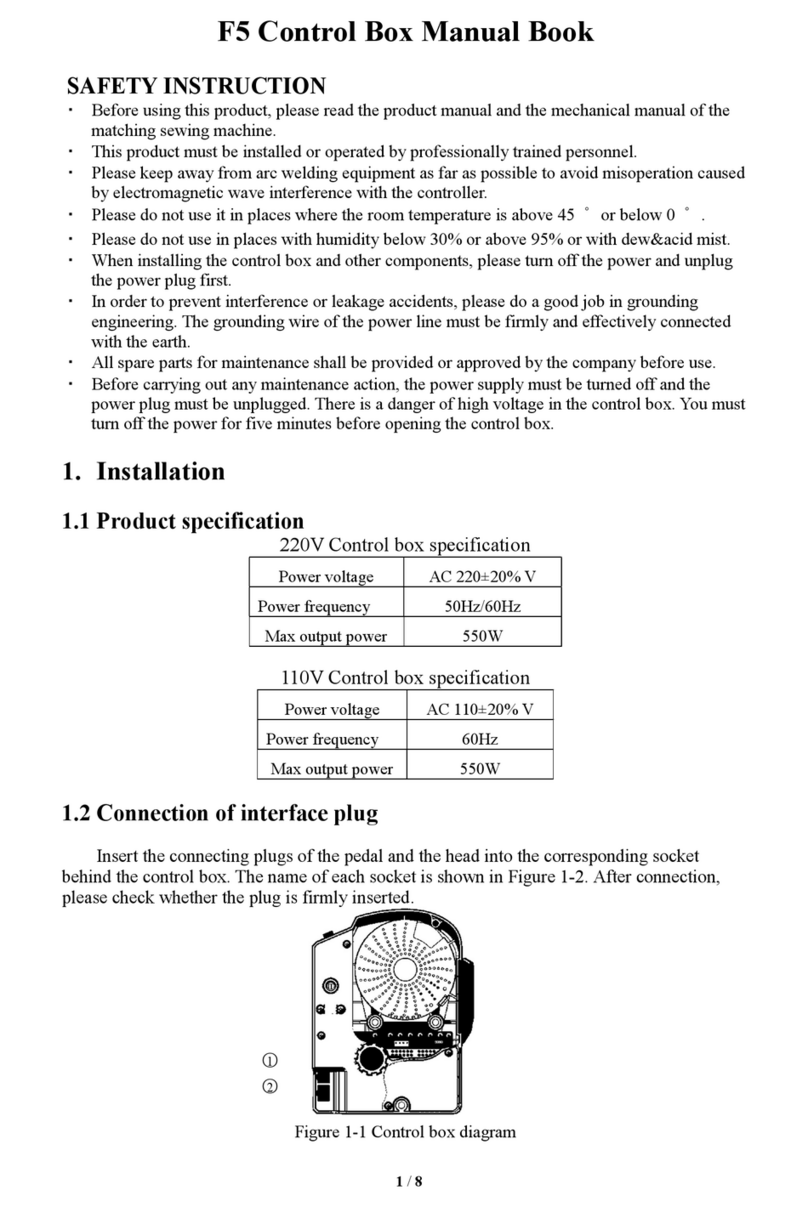

ǃᅝ㺙䇈ᯢĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

,167$//$7,21,16758&7,216

ǃ㾘ḐĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

63(&,),&$7,21

ǃ㒓䗍ᔶᓣĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

7<3(62)67,7&+(6

ǃ㓱㑿ᴎ༈ⱘᅝ㺙ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

6(77,1*837+(0$&+,1(+($'

ǃẁᖗⱘᅝ㺙ᮍ⊩ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

$77$&+,1*7+(%2%%,1

ǃẁⱘᅝ㺙ᮍ⊩ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

,167$//$7,215(029$/2)%2%%,1&$6(

ǃᴎ䩜ⱘᅝ㺙ᮍ⊩ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

+2:72,167$//7+(1(('/(

ǃ㒓ᶊⱘᅝ㺙ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

6(77,1*837+(7+5($'67$1'

ǃࡴ⊍ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

/8%5,&$7,21

ǃᑩ㒓ⱘ㒩㒓ᮍ⊩ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

:,1',1*7+(%2%%21

ǃϞ㒓ⱘこ㒓ᮍ⊩ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

7+5($'7+(1(('/(7+5($'

ǃࡼ䗕ᏗᶘĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

0$18$/)(('+$1'/(

ǃ䰆ℶߛߔᥝ㨑ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

+2:72+2/'7+('(6&(1',1*.1,)(

ǃ䩜᭄ⱘবᤶᮍ⊩ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

&+$1*,1*7+(180%(52)67,7&+(6

ǃᴎ䩜ᮟẁⱘ݇㋏ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

1(('/(72+22.5(/$7,21