[2] Notes on safety

ii

A DANGER

/A

Wait at least 5 minutes after turning

off

the power switch a

nd

disco

nn

ecting the power cord from

th

e wall outlet

~

before opening the cover of

th

e control box. Touching areas where high voltages are present can result in severe

injury.

AcAu110N

Environmental requirements

0 Use t

he

sewing machine

in

an area which is free from

sources

of

strong electrical noise such as electrical

line noise

or

staticelectric noise.

Sources

of

strong electrical noise may cause

problems with correct operation.

0 Any fluctuations

in

the power supply voltage should

bewithin ±10%

of

the

ra

te

d voltage for the machine.

Voltage fluctuations which are greater than this may

cause problems with correct operation.

0 The power supply capacity should

be

greaterthan the

requirements for the sewing machine's power

consumption.

Insufficient power supply capacity may cause

prob

le

mswith correct operation.

0 The pneumatic delivery capability should be greater

than the requirements for the sewing machine's total

air consumption.

Insufficient pneumatic delivery capability may cause

problems with correct operation.

0 The ambient temperature should be within the range

of

5°C to 35°C during use.

Temperatures which are lower

or

higher than this

may cause problems with correct operation.

0 The relative humidity should be within the range

of

45% to 85% during use, and no dew formation should

occur in any devices.

Excessively dry

or

humid environments and dew

formation maycause problems with correctoperation.

0 In

th

e event

of

an

electrical sto

rm

, tu

rn

off the power

and disconnect the power cord from the wall outlet.

Lightning may cause problemswith correct operation.

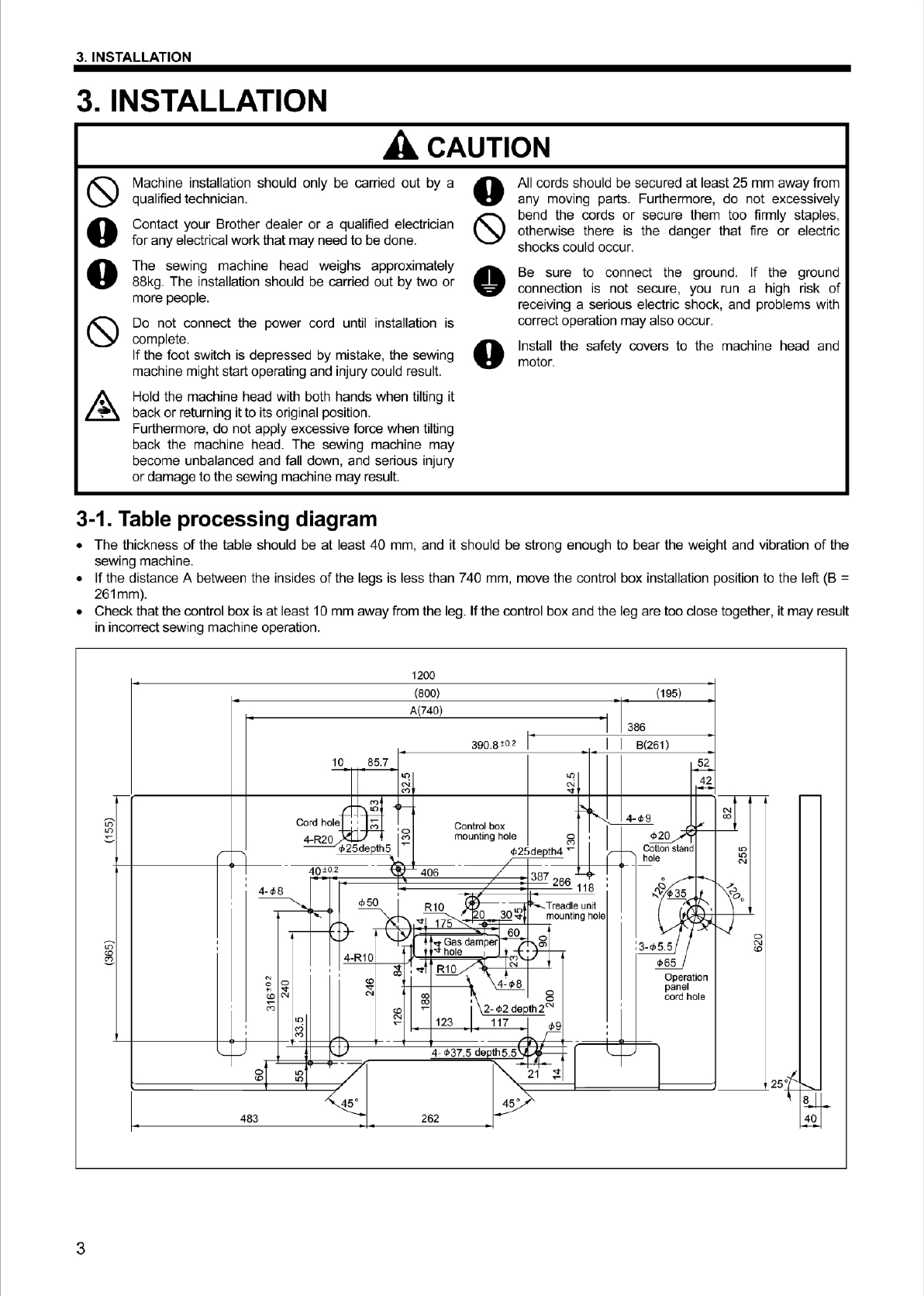

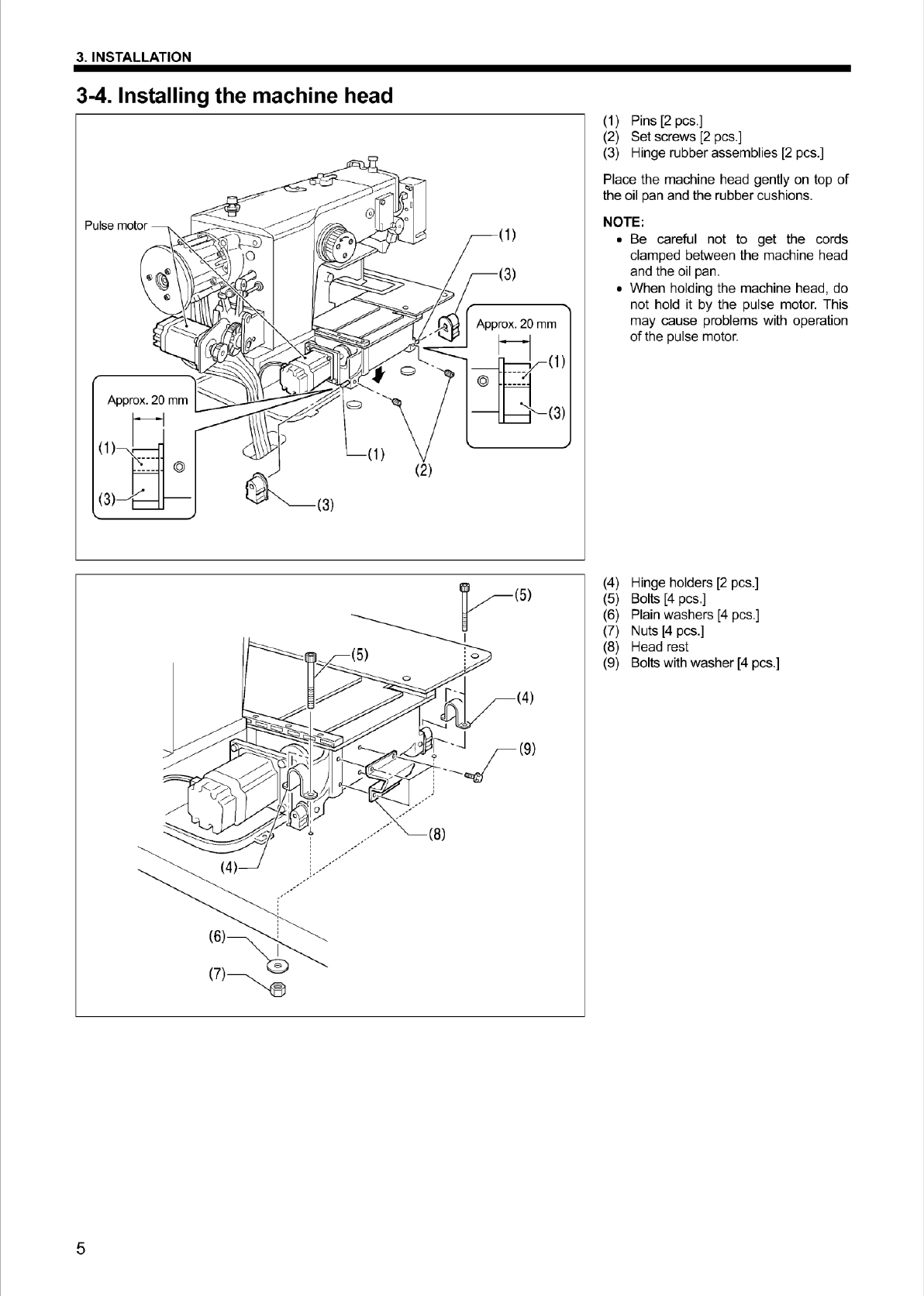

Installation

t<::\

Machine installation should only be ca

rri

ed out by a

\.Y

qualified technician.

0

0

Contact your Brother dealer

or

a qualified electrician

for any electrical work that may need to be done.

The sewing machine weighs approximately 88 kg.

The

in

stallation should be carried out by two

or

mo

re

people.

t<::\

Do not connect the power cord until installation is

\.Y

complete.

If

the foot switch is depressed by mistake,

the sewing machine might start operating and injury

could resul

t.

A Ho

ld

the machine head with both hands when tilting it

~

back or returning itto itsoriginal position.

Furthermore, do not apply excessive force when

tilting back the machine head. The sewing machine

may become unbalanced and fall down, and ser

io

us

injury or damage to the sewing mach

in

e may resul

t.

• Be sure to connect the ground.

If

the ground

connection is not secure, you

ru

n a high risk

of

receiving a serious electric shock, and problems with

correct operation may also occur.

0 All cords should be secured at least 25 mm away

from any moving parts. Furthermore, do not

excessively bend the cords

or

secure them too firmly

t<::\

with staples, otherwise there is the danger that fire

or

\.Y

electric shocks

cou

ld occur.

0

0

Install the safety covers to the machine head and

motor.

If using a work table which has casters,

th

e casters

should be secured

in

such a way so that they cannot

move.

t<::\

Be sure to wear protective goggles and gloves when

\.Y

handling the lubricating

oi

l and

gr

ease, so that they

do not get into your eyes

or

onto your skin.

If

the oil

and grease get into your eyes

or

onto yo

ur

skin,

inflammation can resul

t.

Furthermore, do not drink or eat the lu

br

icating oil

or

grease. They maycause diarrhea or vomiting.

Keep the oil out

of

th

e reach

of

children.

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com