目录CONTENT

1.主要技术规格............................................................................................................................................................................................................................... 1

2.操作准备....................................................................................................................................................................................................................................... 1

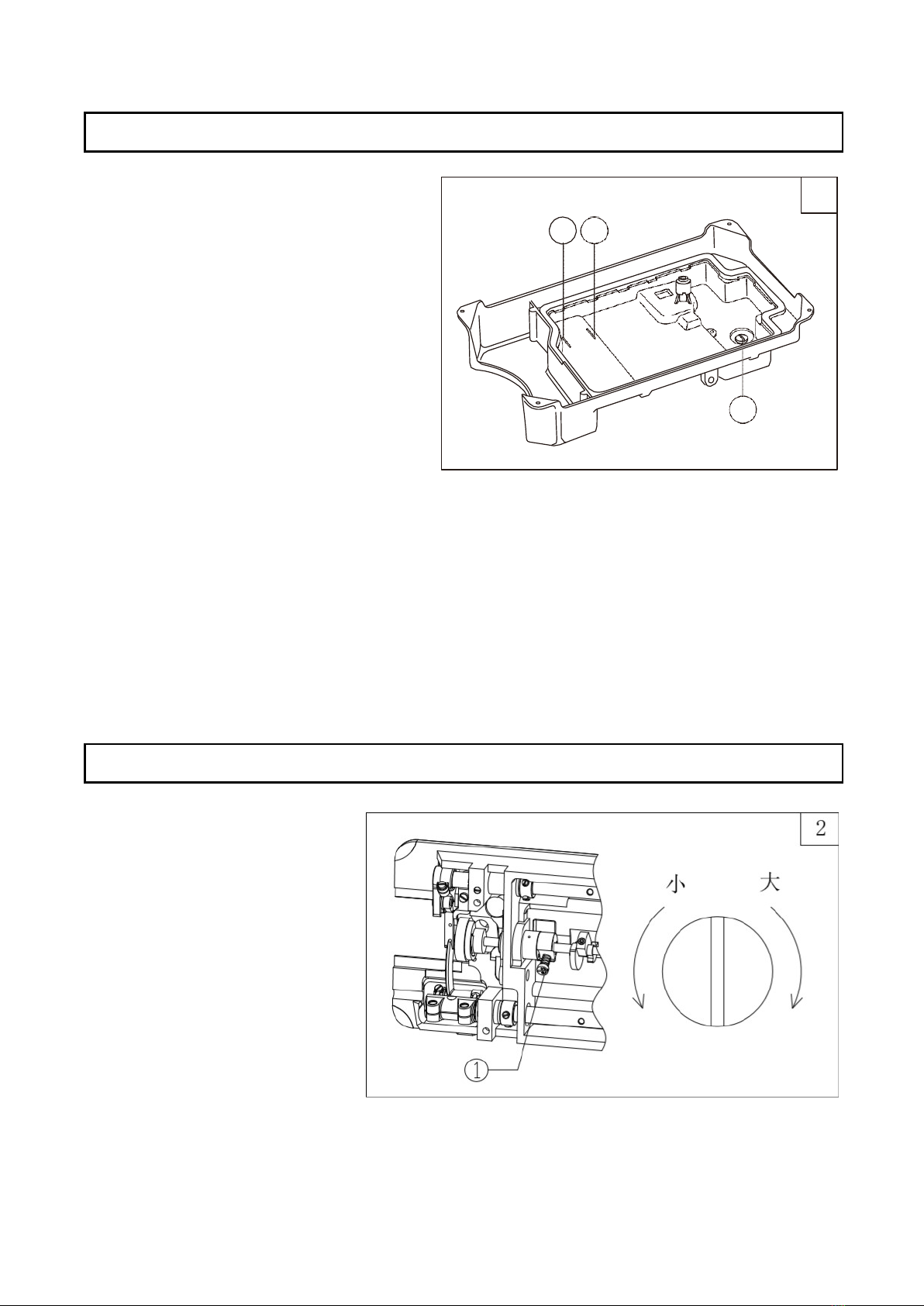

3.润滑(图 1)/Lubrication(Fig1)............................................................................................................................................................................................ 2

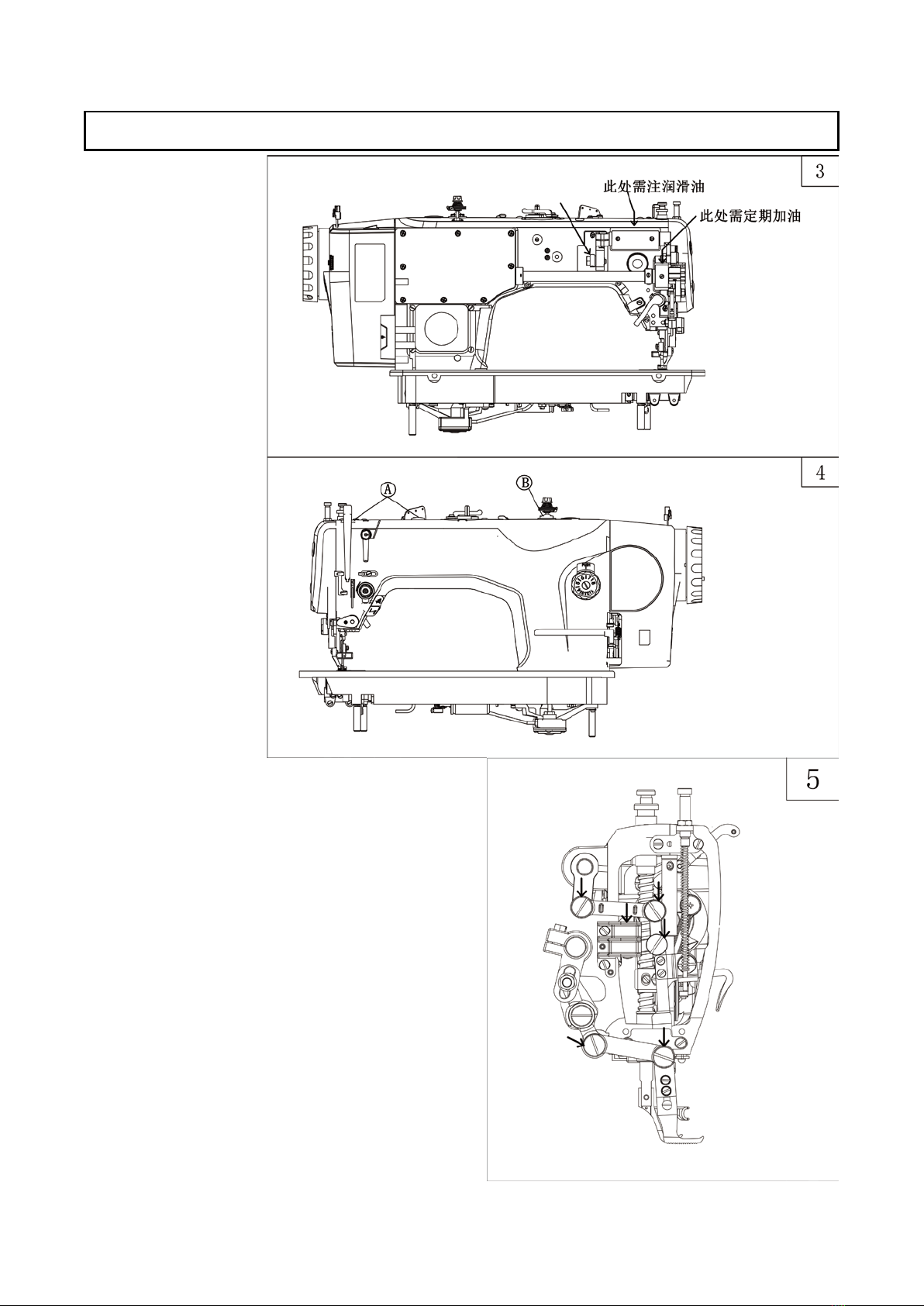

4.调节旋梭油量(图 2)/Adjusting the amount of oil in the hook(Fig 2) ..................................................................................................................................... 2

5.试车(图 3、4、5)/Test run(Fig 3 4 5).............................................................................................................................................................................. 3

6.油泵进油调节(图 6)/OIL PUMP SUPPLY ADJUSTMENT(Fig 6)........................................................................................................................................ 4

7.安装机针(图 7)/Installing the needle(Fig 7).................................................................................................................................................................... 4

8.机针、缝线和缝料的配合(图 8)/ Matching of needle, suture and sewing material(Fig 8)......................................................................................... 5

9.穿面线(图 9)/ Noodle thread(Fig 9)................................................................................................................................................................................. 5

10.绕线调节(图 10)/winding the bobbin thread (Fig 10) ........................................................................................................................................................ 6

11.针距、倒顺送料(图 11)/ Needle pitch, reverse feed(Fig 11)....................................................................................................................................... 6

12.挑线部位进油(图 12)/ Oil in the thread take-up part(Fig 12)...................................................................................................................................... 7

13.压脚压力调节(图 13)/ADJUST THE PRESSURE OF PRESSER EOOT(Fig 13)................................................................................................................... 7

14.缝线张力(图 14 15)/Suture tension(Fig 14 15)............................................................................................................................................................. 8

15.挑线簧调节(图 16、17)/ Thread take-up spring adjustment(Fig 16 17)..................................................................................................................... 9

16.底面线张力调节(图 18、19、20)/ Bottom thread tension adjustment(Fig 18 19 20)............................................................................................ 10

17.机针与旋梭同步调整(图 21.22.23.24)/ Synchronous adjustment of needle and rotary hook(Fig 21 22 23 24).................................................... 11

18.旋梭装卸(图 25)/ Hook loading and unloading(Fig 25).............................................................................................................................................. 12

19.送布牙安装(图 26、27)/ Feed dog installation(图 26 27)......................................................................................................................................... 12

20.送布牙平面调节(图 28)/ Feeding tooth plane adjustment(Fig 28)........................................................................................................................... 13

21.针距误差调节(图 29)/ Synchronous feeding adjustment(Fig29)............................................................................................................................... 13

22.送布同步调节(图 30,31,32)/ Synchronous feeding adjustment(Fig 30 31 32)......................................................................................................... 14

23.松线器挺线调节(图 33)/ Adjust opening time of the tension discs(Fig 33).............................................................................................................. 15

24.上送料机构的调节(图 34)/Adjusting the tension releasing mechanism(Fig 34)...................................................................................................... 15

25.压脚交叉提升机构的调节(图 35)/Adjusting presser foot alternate lift mechanism(Fig35).................................................................................... 16

26.摆压脚、小压脚总提升量的调节(图 36)/Adjusting the lift amount of presser foot together with walking foot(Fig36)...................................... 16

27.摆压脚、压脚前后方向间隙的调节(图 37)/Adjusting the clearance between presser foot and walking foot(Fig 37)......................................... 17

28.定期清扫(图 38,39,40)/ Clean regularly(Fig 38 39 40)............................................................................................................................................... 17

29.工业缝纫机安全使用注意事项/ /Notes for safe use of industrial sewing machines.......................................................................................................... 18

30.环保要求/Environmental requirements.................................................................................................................................................................................. 18