OPERATING MANUAL 06-2021 6/8

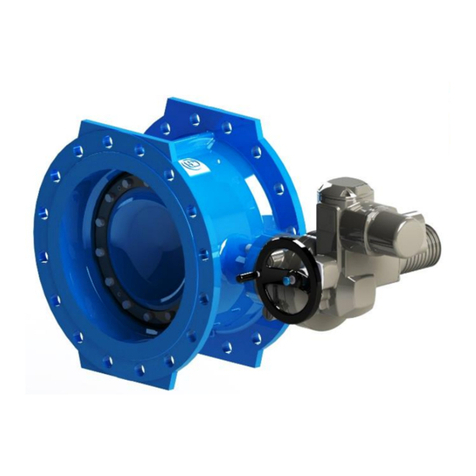

Protect the rubber parts from compression by keeping the gate valve wedge closure halfway open. Secure the

products against shifting during shipping and handling. Heavy gate valves (DN350 and larger) shall be handled

with dedicated eye bolts; the gate valves from DN65 to DN300 shall be handled on slings (see the example diagram

below) and secured from rotating.

5. INSTALLATION

The flanged gate valves with soft seals can be installed in underground pipelines (except for P/N 2511 and 2502,

the buried installation of which requires a suitable chamber / vault) or overground pipeline installations, both

horizontal and vertical, with any direction of flow of the medium. Do not install the gate valve with the spindle

downward. The listed products are suitable for joining with the flanged ends of pipelines with the size equal to

that of the valve flanges. Note that the completed installation must not expose the valve to bending or tensile stress

from loading with the unsupported pipeline sections, and the valves must be installed aligned with the piping.

Consider proper compensation of the pipeline dimensional changes from temperature and pressure in the

installation. The gate valve is ready for installation as assembled and adjusted by the manufacturer. Any

dismantling of the gate valve components may result in loss of seal.

Before attempting to install the valve, check the technical and commercial documents delivered with the product

to verify that your media and pipeline operating parameters comply with the manufacturer's declaration. Any

change in the operating conditions must be consulted with the manufacturer beforehand.

Before attempting to assemble the valve, remove the main bore plugs, check the inner surfaces of the valve and

thoroughly flush with water, if necessary. Install the gate valve on a base or a support adequate to the size and

weight of the valve, to prevent strain of the piping with the valve. Use suitable piping flanges, gaskets and bolts

for the valve flange ends. The valve and piping flange holes must be aligned. Tighten the connection flange bolts

crosswise to ensure a proper seal pressure. The gate valve location must prevent exposure to freezing of the

medium flowing through the gate valve. Equip the gate valve with a suitable control - an electric drive unit. When

installing a housing, it is necessary to equip the unit with a street box founded on a base slab. When using a spindle

extension, make sure that the weight of the extension is not transferred to the gate valve spindle. To prevent the

load transfer, use holding pieces, mounted to the chamber/vault walls. Spindle extensions over 3000 mm long shall

be attached via Cardan joints. Having completed the installation, perform a pressure test at a maximum test

pressure equal to 1.5 times the nominal pressure.

Caution! If the product has mechanical damage, do not install it in the pipeline.

Caution! When mounting the valve with the electric actuator in the horizontal position, it is absolutely

necessary to use a support or slings in order to relieve the valve, see example below.