Usage Precautions

—5 —

SW-4000Q-SFP

Notes on cable configurations

The presence of lighting equipment and television receivers nearby may result in video noise.

In such cases, change the cable configurations or placement.

Notes on attaching the lens

Avoiding dust particles

When attaching the lens to the camera, stray dust and other particles may adhere to the sensor surface

and rear surface of the lens. Be careful of the following when attaching the lens.

• Work in a clean environment.

• Do not remove the caps from the camera and lens until immediately before you attach the lens.

• To prevent dust from adhering to surfaces, point the camera and lens downward and do not allow the

lens surface to come into contact with your hands or other objects.

•Always use a blower brush to remove any dust that adheres.

Never use your hands or cloth, blow with your mouth, or use other methods to remove dust.

Phenomena specific to CMOS image sensors

The following phenomena are known to occur on cameras equipped with CMOS image sensors.

These do not indicate malfunctions.

• Aliasing

When shooting straight lines, stripes, and similar patterns, vertical aliasing (zigzag distortion) may appear

on the monitor.

• Blooming

When strong light enters the camera, some pixels on the CMOS image sensor may receive much more

light than they are designed to hold, causing the accumulated signal charge to overflow into surrounding

pixels. This “blooming” phenomenon can be seen in the image, but does not affect the operation of the

camera.

• Fixed pattern noise

When shooting dark objects in high-temperature conditions, fixed pattern noise may occur throughout

the entire video monitor screen.

• Defective pixels

Defective pixels (white and black pixels) of the CMOS image sensor are minimized at the factory according

to shipping standards. However, as this phenomenon can be affected by the ambient temperature,

camera settings (e.g., high sensitivity and long exposure), and other factors, be sure to operate within the

camera’s specified operating environment.

Notes on exportation

When exporting this product, please follow the export regulations of your country or region.

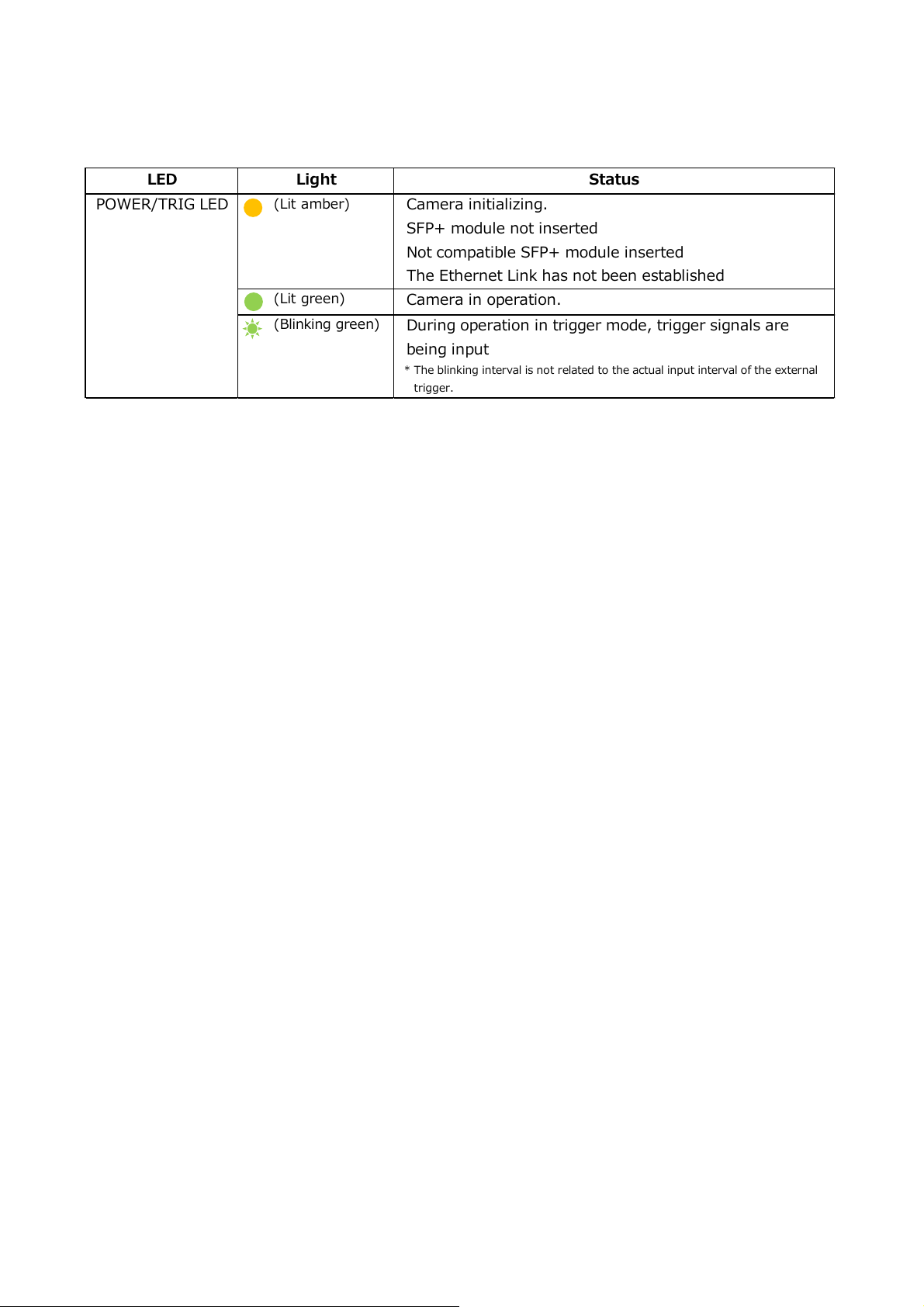

Notes on SFP+ module installation

Check the operation manual of the SFP+ module to be used, and attach it or remove it from the camera.

The SFP module can be attached to and removed from the camera only when the camera is turned off.

Many SFP modules and fiber optic cables are Class 1 laser products. Do not look into connectors and cables

when installing or removing. There is a risk of injury to eyes.

Notes on temperature conditions

The guaranteed operating temperature and humidity of this camera are -5℃ to +45℃, 20% to 80%

(non-condensing). Please make sure the following temperature condition is met when operating the unit.

1) The camera's internal temperature sensor detects temperatures of 65 °C or less during operation.

If the above temperature conditions are exceeded, take measures to dissipate heat according to your

installation environment and conditions.

In addition, the operating temperature range of SFP+ modules varies depending on the product.

Please use it after confirming the specifications in the data sheet of the product to be used.

Depending on the operating environment, the surface of the camera

may become very hot during operation.

Do not touch the camera during operation and while it is being cooled.

Also, make sure that the cable surface and other easily deformable

items do not contact the surface of the camera.