AIR HOSE REEL

PRO SERIES - CONTROLLED

RETURN

Extreme Ultraex Reinforced Hose is a special blend of hose that has been

developed for today’s demanding conditions, it stay exible in the cold and

doesn’t kink in the heat, allowing full ow in all-weather conditions.

It’s a tough hose for tough conditions

FEATURES

■Hose layering system

■Auto lock / auto rewind

■Solid brass internal spindle

■No tools required adjustable hose stop

■Wall mount with 180° pivot

■Weather resistant UV stabilised polypropylene case

■Leader hose 2 m with brassttings

■Includes Jamec Pem Extreme Ultraex Hose

SPECIFICATIONS

Part no. 58.5089 (58.5089NA) 58.5056

Hose length 20 m (65 FT) 15 m

Hose I.D 9.2 mm (3/8") 12.5 mm (1/2")

Hose O.D 15.2 mm (5/8") 18.5 mm (3/4")

Leader hose length 2 m (6.5') with 1/4" BSP Male

tting (1/4") 2 m with 3/8" BSP Male tting

Hose material Extreme Ultraex Reinforced

Hose Reinforced PVC braided

Reel / case type Controlled return /

polypropylene

Controlled return /

polypropylene

Auto lock / rewind Yes Yes

Max. working

pressure 300 psi 300 psi

Fitting size 1/4" BSP Male (1/4") 3/8" BSP Male

Bracket 180° Pivoting 180° Pivoting

Weight - kg 8.6 8.6

Product dimensions 569 L x 246.4 W x 441.6 D mm 569 L x 246.4 W x 441.6 D mm

Advised application Air Air (high volume)

SPECIFICATIONS

Part no. 58.5034 58.5012

Hose length 20 m 32 m

Hose I.D 9.5 mm (3/8") 8 mm (5/16")

Hose O.D 16 mm (5/8") 12 mm 1/2")

Leader hose length 2 m with 1/4" BSP Male tting 2 m with 1/4" BSP Male tting

Hose material Reinforced PVC braided Reinforced PU braided

Reel / case type Controlled return /

polypropylene

Controlled return /

polypropylene

Auto lock / rewind Yes Yes

Max. working

pressure 300 psi 250 psi

Fitting size 1/4" BSP Male 1/4" BSP Male

Bracket 180° Pivoting 180° Pivoting

Weight - kg 8.8 9.7

Product dimensions 569 L x 246.4 W x 441.6 D mm 569 L x 246.4 W x 441.6 D mm

Advised application Air Air (long reach)

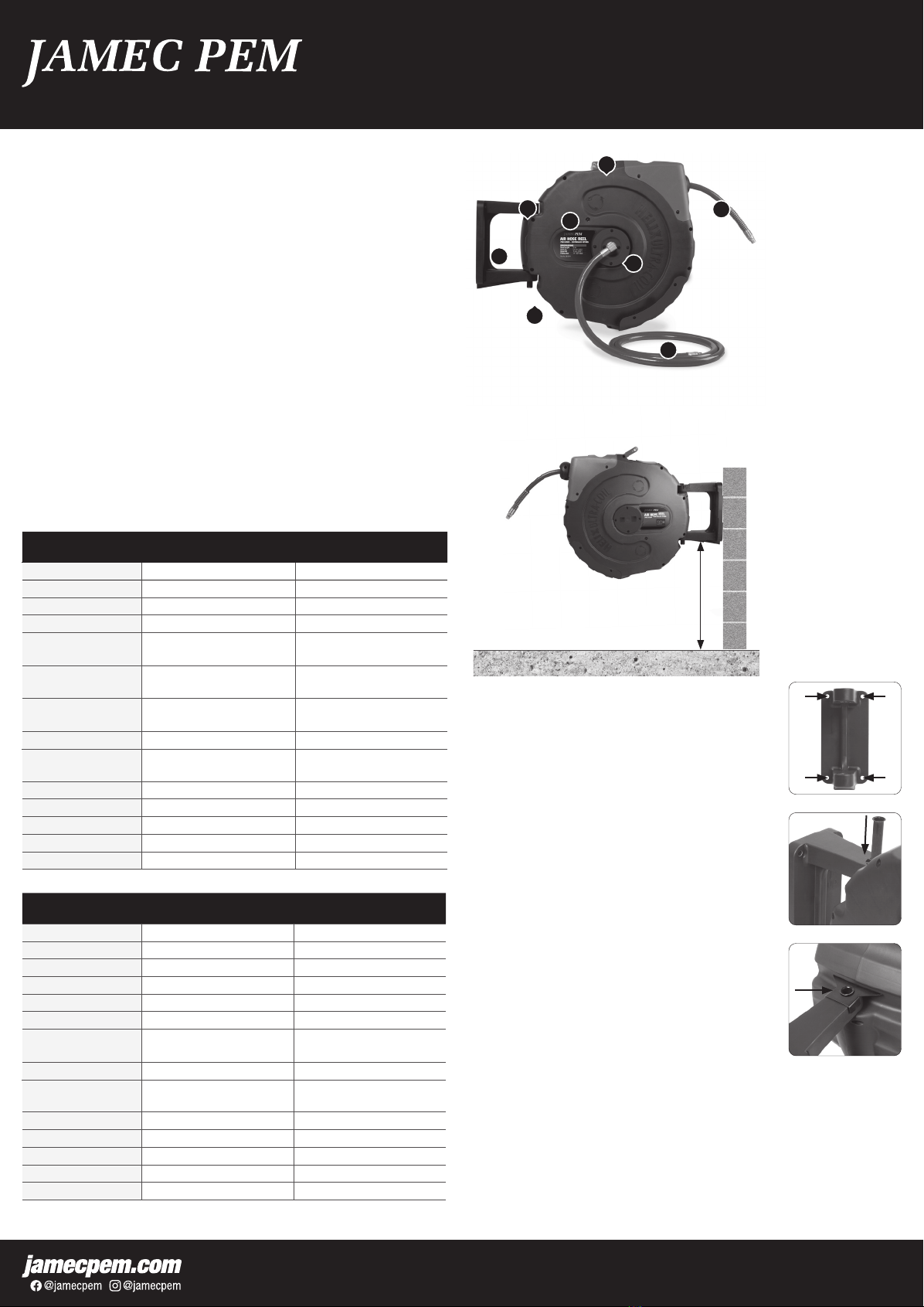

1

48

7

2

3

6

5PRODUCT

IDENTIFICATION

1. Mounting Bracket

2. Optional Fixed In-line

Locking Plate

3. Pivot Pin

4. Fully Enclosed Case

5. Carry Handle

6. Solid Brass Internal

Spindle

7. 2 metre Leader Hose

8. Hose with Adjustable

Stopper

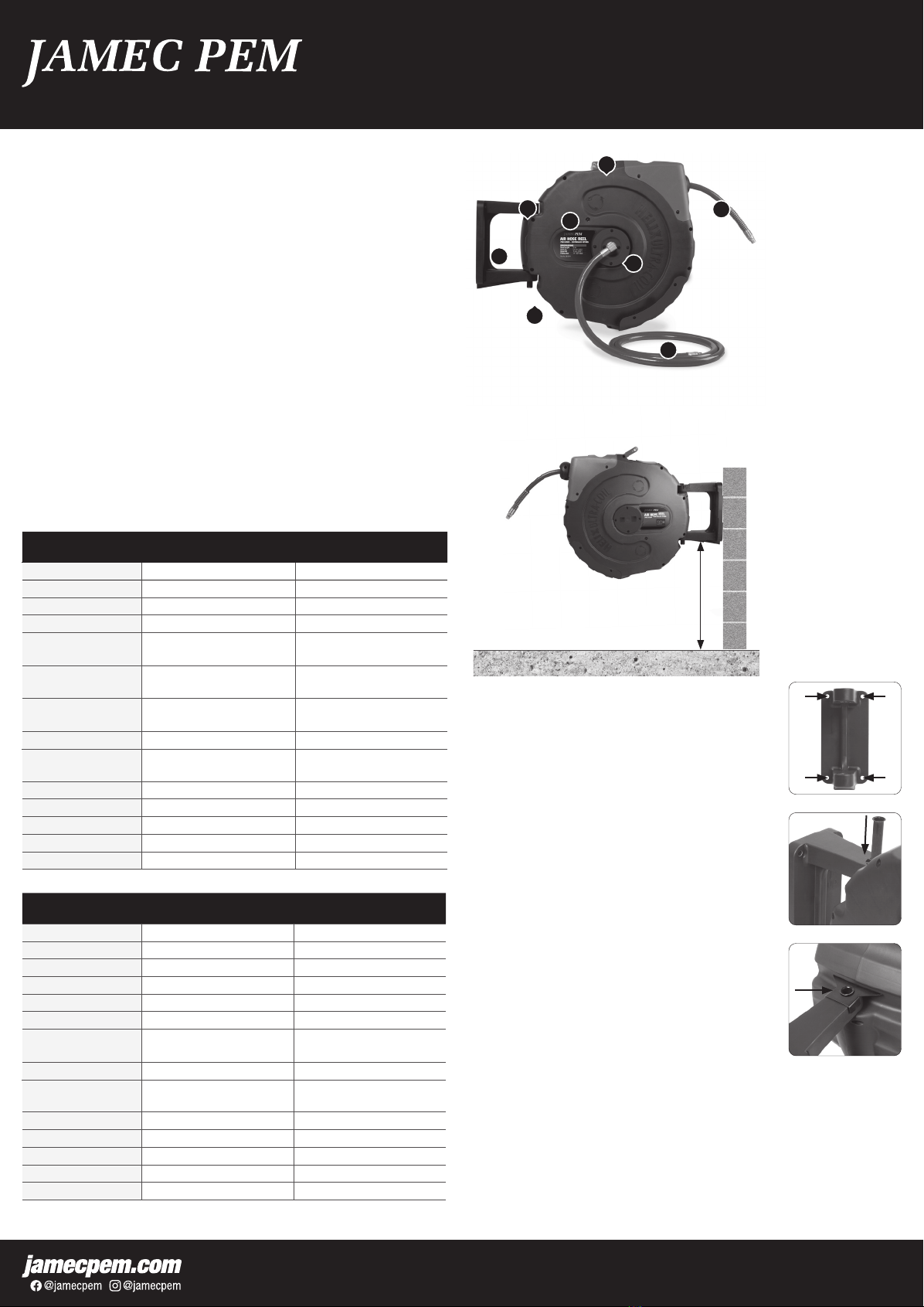

INSTALLATION

The JamecPem Air Hose Reel Pro Series Controlled Return

can be mounted in a horizontal or vertical position.

1. Chose a location that is near to the compressed air source.

2. For large areas, place the hose reel at the centre of the

work area.

3. When mounting the hose reel vertically, ensure there is

adequate clearance under the reel to prevent injury or

damage.

4. Mounting bracket must be installed on a at surface.

Note: It is recommended to install the mounting bracket 0.8

metre (minimum) above

the oor level.

5. Drill 4 x M8 holes to match the holes located in the

Mounting Bracket. (Fig. 1)

6. Connect the hose reel to the Mounting Bracket with the

Pivot Pin. (Fig. 2)

Note: For xed in-line position, t the locking plate onto the

Mounting Bracket prior to inserting the pivot pin. (Fig. 3)

7. Connect the inlet leader hose to the compressed air source.

Note: Apply thread sealing tape to all air line and air hose

ttings.

0.8 METRE MIN.

Fig. 1 Mounting Bracket

Fig. 2 Pivot Pin

Fig. 3 Locking Plate