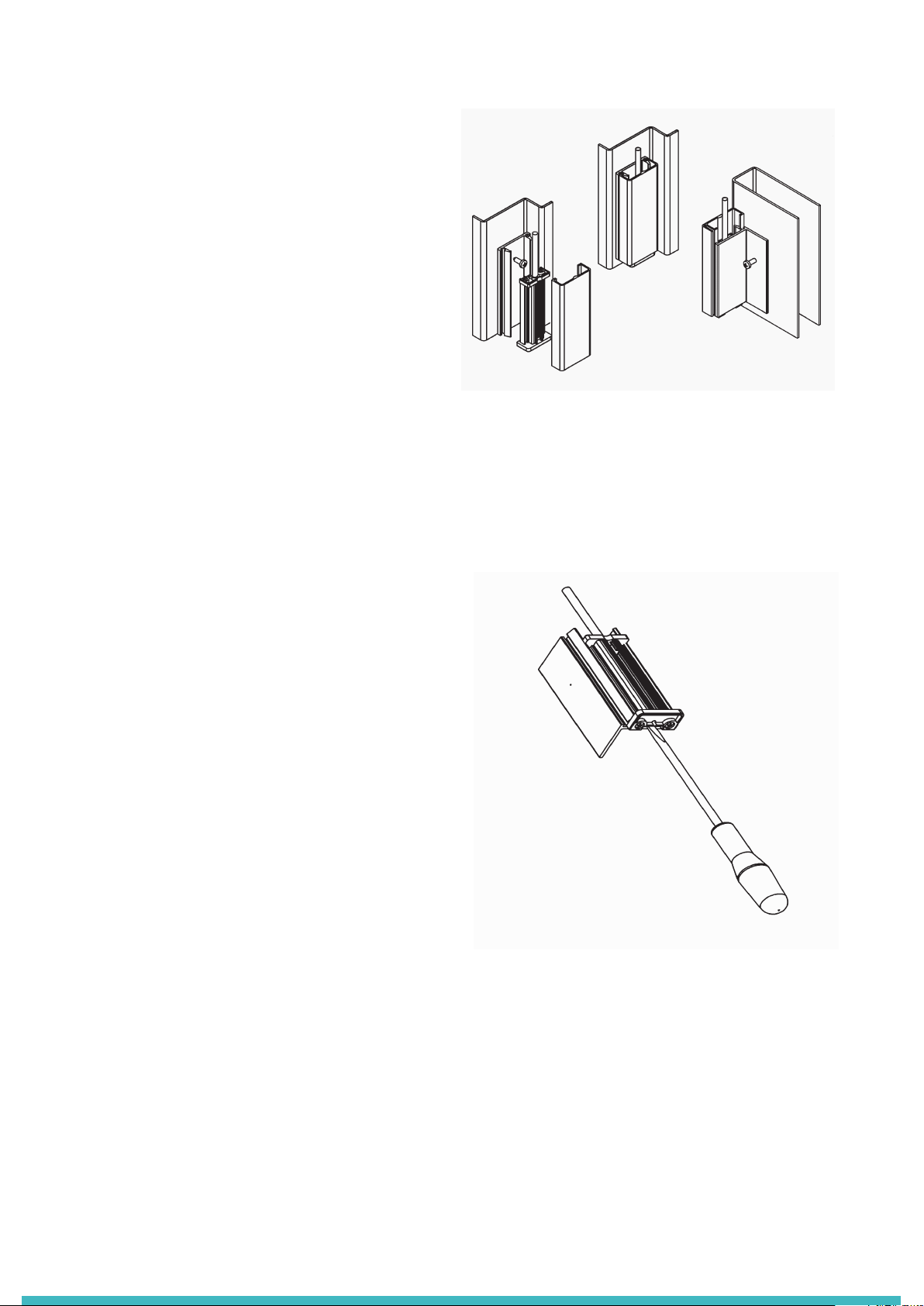

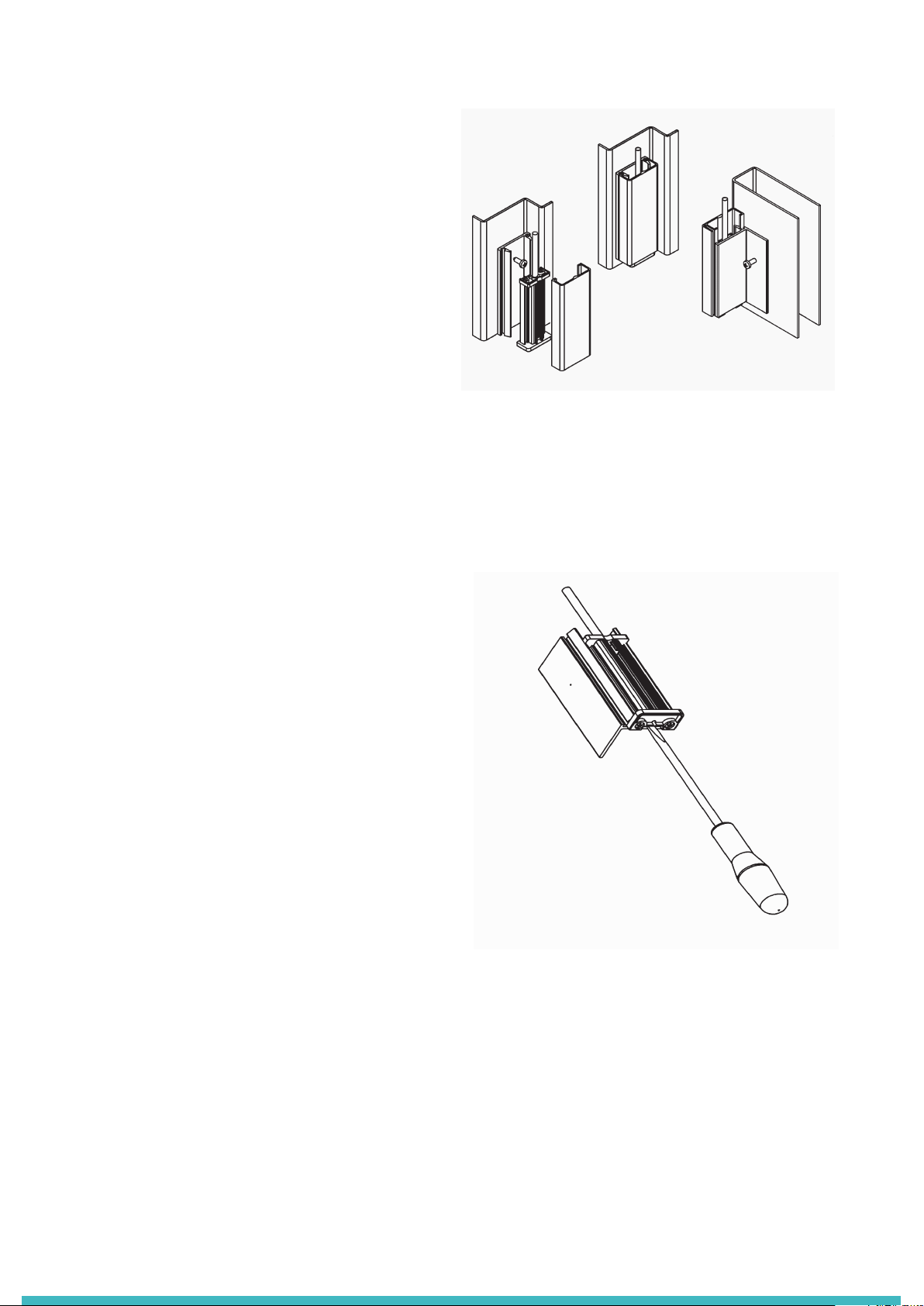

Side-Opening Installation

1. Use the CENTRE-OPENING INSTALLATION directions

to mount the antenna on the door.

2. Remove the uPVC cover from the remaining antenna.

3. Using a screwdriver, pry the aluminium section from

the plastic L channel (see Fig 3).

4. Position the strikepost bracket (plastic U-shaped

channel) approximately 1/2”-3/4” above the car sill

consistent with door edge.

5. Use 5 No.8 pan-head self-tapping screws to secure

the plastic U-shaped channel to the strikepost; ensure

the screws are centred in the channel and evenly

spaced along the length of the bracket.

6. Align the aluminium channel with the bottom of the

bracket and snap into position.

7. Attach the green & yellow ground wire located at the

top of the antenna to the strikepost using a self-

tapping screw and lock washer. The ground wire must

be tted to ensure a proper ground

8. Snap on the uPVC lens.

9. Attach cable securely with the “P” clips and screws

provided.

System Connection with Model 280, see Fig 4

The Model 280 power supply provides a regulated DC

supply for the detectors and a voltage-free relay contact

to re-open the elevator doors.

1. Position the Model 280 close the centre of the car top

within reach of both RX and TX cables.

2. Plug in RX and TX cables as shown in Fig 4.

3. Connect the relay output to the “Door Re-Open” or

“Safety Edge” input of the door operator elevator

controller. The Model 280 provides voltage-free

contacts as follows:

+‘COM’ = common

+‘N/C’ = normally closed

+‘N/O’ = normally open

4. Connect the Model 280 to a 240V or 110V AC mains

supply.

5. Set SW2 NPN and SW3 to N/C.

6. When power is applied, a tone should be heard when

a person or object is detected. This tone can be

switched on or o by using SW1.

Fig 2: Strikepost Installation

Fig 3: Strikepost Installation