5 / 11

MO 0688-1101

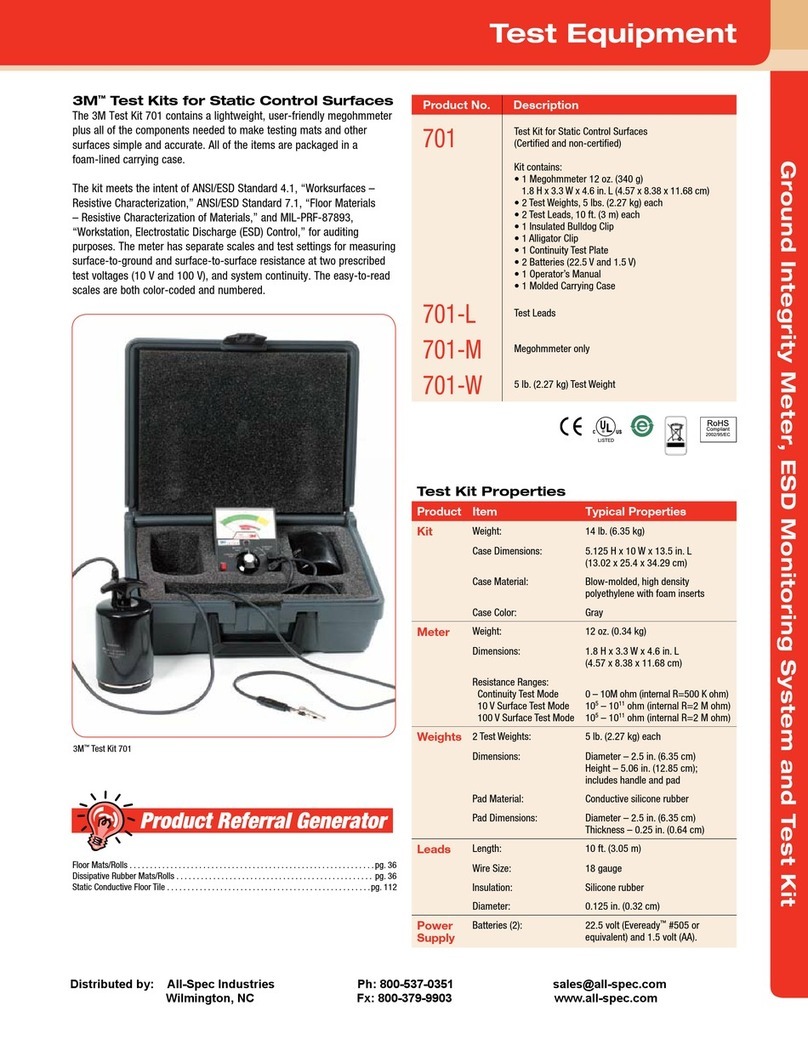

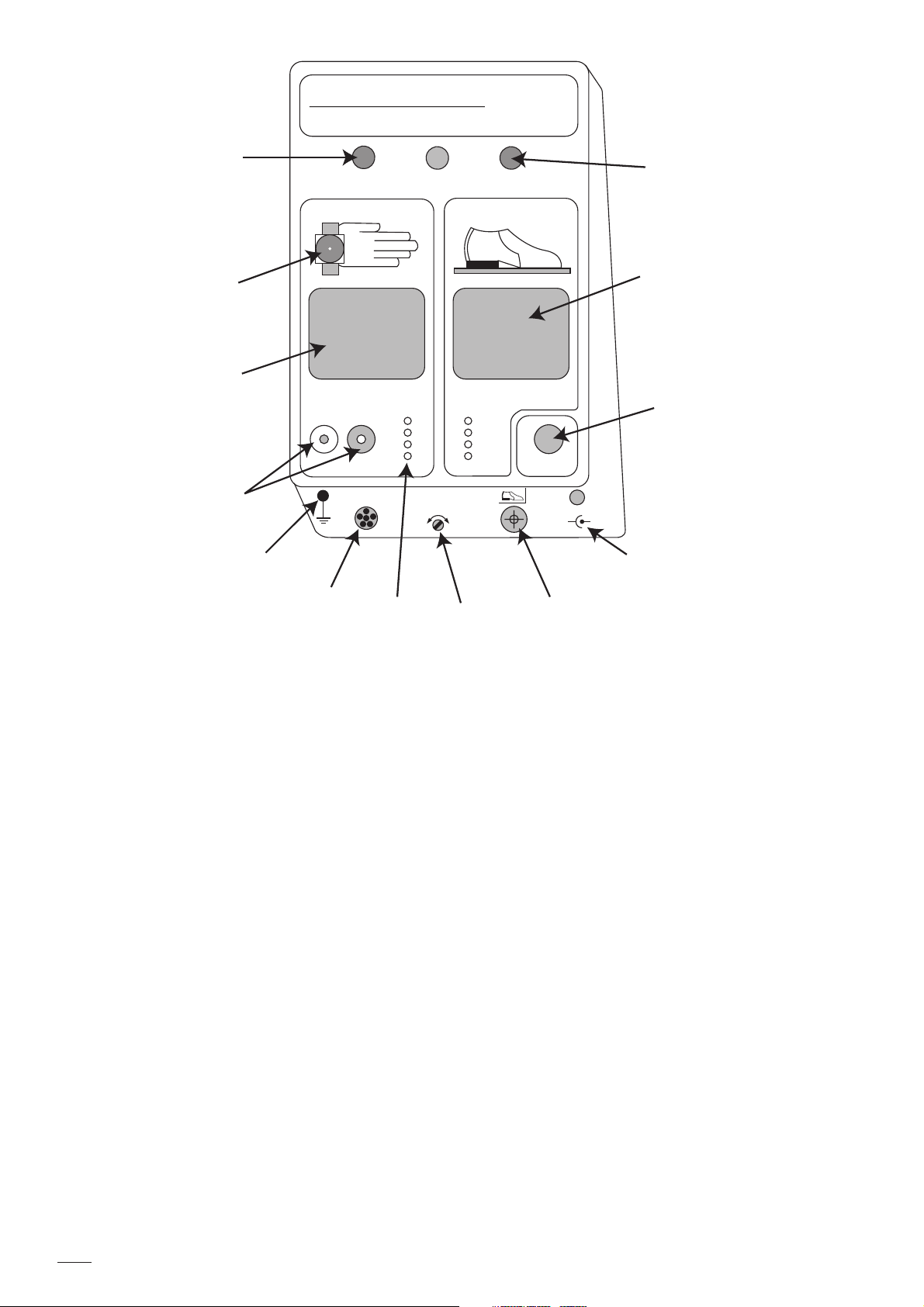

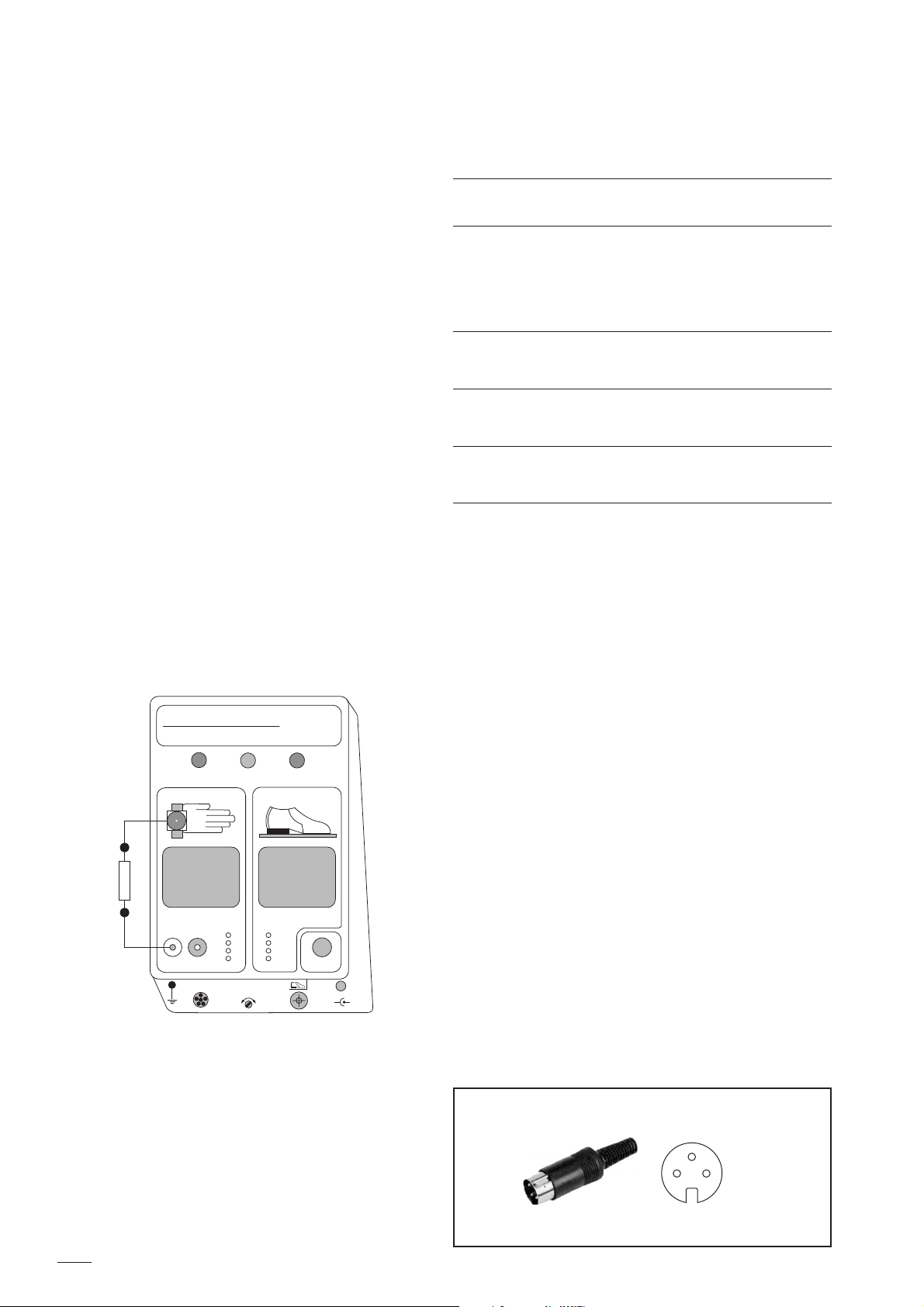

VII. Shoe test

Either the 741/741D shoe electrode must be

connected to the 740 shoe jack.

a) when the 741 single shoe electrode is

used:

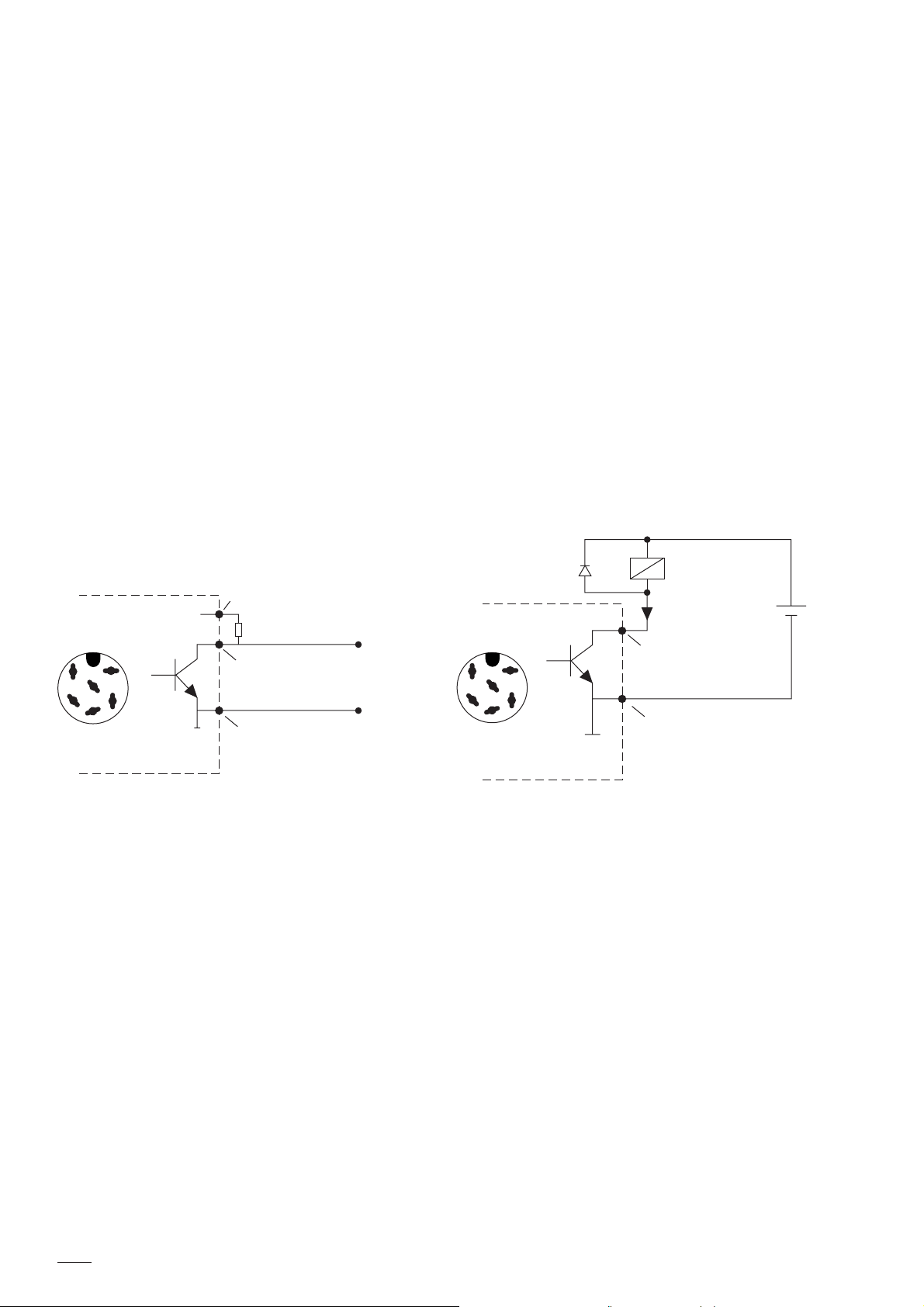

If the red "> "-LED is illuminated, clean the soles

of the shoes or check shoe grounding system (heel

ground or toe ground strap) and retest. If, after

cleaning, the red "> "-LED remains lit, replace it

by an appropriate device. If the red "< "-LED is

illuminated, the minimum resistance of the shoes

or shoe grounding system is under 750 kΩ.

An electrical hazard to personnel may exist at the

work place.

b) when the 741D dual shoe electrode is

used:

The dual shoe electrode allows differentiation

between the right and left shoe; giving the right

shoe a preference in indication. This means, if

both shoes or just the right one are out of range,

you will get identical indications as it would be

with the single shoe electrode. If just the left shoe

is out of range, the corresponding red LED will

flash. Consequently, in case of a steadily lit red

LED, you shall clean or remove right shoe first

and retest. If the right shoe is in the "ok"-range

then, you will obtain information about

performance of the left shoe and you can react

accordingly.

The shoe test does not influence the wrist strap

test, therefore the shoes can be tested while the

wrist strap is still connected to the 740 or the wrist

strap can be tested while the operator is standing

on the 741 shoe electrode. Both metal plates shall

not be pressed at the same time.

Switch the 740 on. Stand on the applied shoe

electrode. If you are using shoe straps with a

1MΩ- resistor on both feet to be tested with the

741 shoe electrode, you have to test the straps one

after the other, to avoid a red "too low" -

indication. Care must be taken not to put the non-

tested foot on ESD - protective flooring to avoid a

bypass to ground. Depress the metal contact plate

for shoe test until one of the indicator - LEDs

lights up. The green LED indicates that the

resistance of the person through the footwear is in

the range between 750 kΩand the desired upper

maximum level (10, 35, 50 or 100 MΩ).