Metrix HI-903 User manual

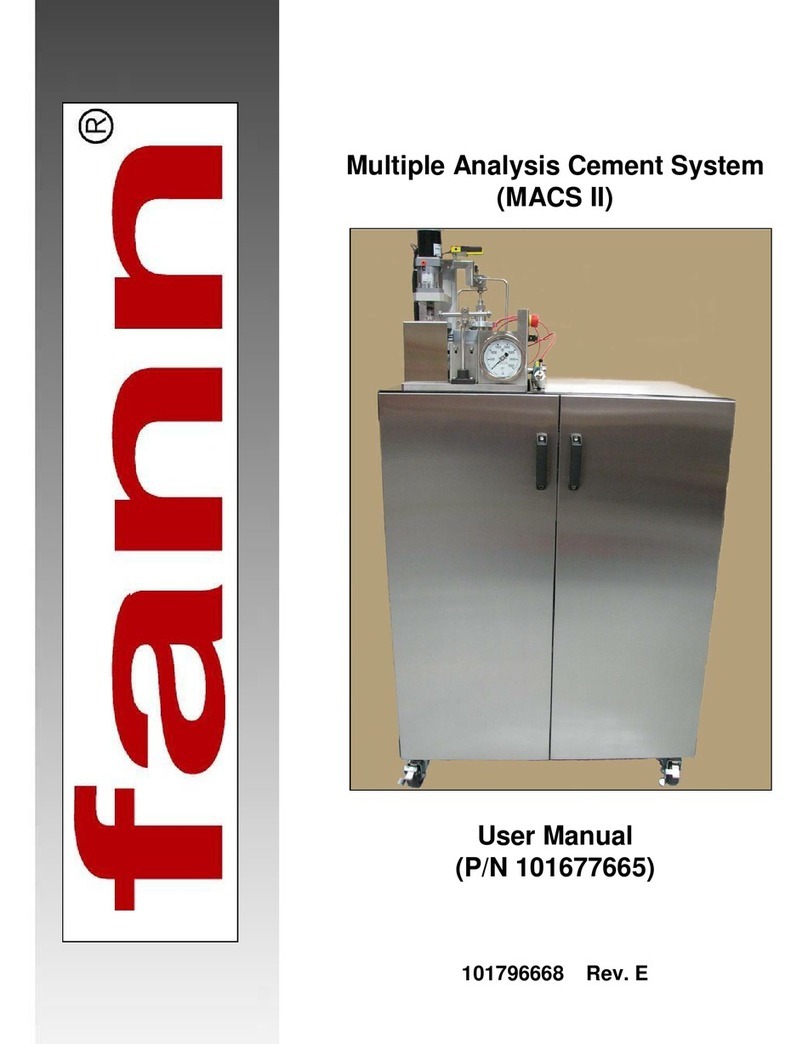

HI-903 HARDY SHAKER

Installaon Manual

DOC# 100928 • REV A (October 2017)

1180

1. OVERVIEW

The METRIX Model HI-903 Portable

Vibraon Calibrator provides a eld

tested method for on-the-spot dynamic

vericaon of accelerometers, velocity

pickups and non-contact displacement

transducers. Oponal mounng xtures

and hardware needed to connect

transducers to the HI-903 mounng

plaorm are available upon request.

A closed-loop control algorithm provides

enhanced stability and accuracy of

frequency and amplitude levels.

The HI-903 incorporates a built-in

sine wave oscillator, power amplier,

electrodynamic shaker, NIST traceable

reference accelerometer, digital display,

and internal memory. The HI-903 is

completely self-contained and operates

on baery or AC power.

The built-in reference accelerometer

is aached permanently to the shaker

armature, maximizing the accuracy

between the reference accelerometer

and the test transducer. The HI-903 is

designed to provide long-term reliable

performance over the frequency range of

7 Hz to 10 kHz. The HI-903 can be used

for a variety of applicaons that include:

• Vericaon and calibraon of

vibraon transducers and related

vibraon test systems

• Vericaon of connector and cabling

integrity

Conrm machine vibraon alarm trip

points are set properly and ensure

end-to-end funconality of vibraon

monitoring systems.

Notes

• Loads of up to 800 gram (28.3

oz) can be mounted directly to

the HI-903 mounng plaorm.

Larger loads may be applied to the

plaorm, however, if prolonged

tesng of a heavy load is planned,

we recommend using an external

transducer suspension system.

Under these condions the vibraon

waveform should be viewed on the

oscilloscope to aid in posioning

the test transducer and plaorm to

reduce distoron that can occur with

very heavy weights.

Doc# 100928 • HI-903-Shaker • October 2017-RevA Page 2 of 33

• The HI-903 should always be operated on a stable, at surface.

The HI-903 is designed for eld test applicaons but care must be taken to maintain

the integrity of the mounng plaorm assembly

• Hearing protecon recommended when operang the HI-903 for an extended

amount of me

Accessories

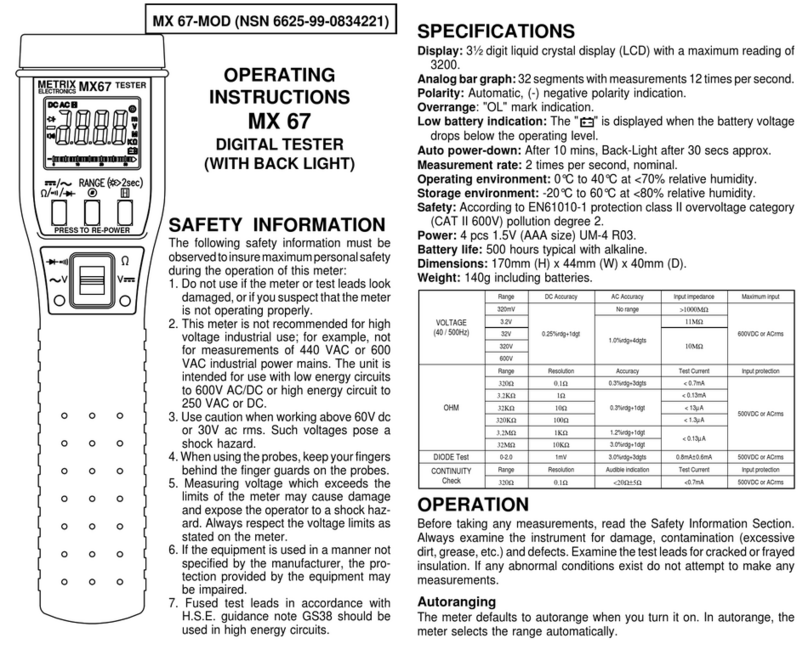

Accessories pictured below are included with each HI-903 Portable Vibraon Calibrator.

Mounng Wrench

1-Mounng Pad

2-1/4-28 to 1/4-28 Adapter

3-10-32 to 1/4-28 Adapter

Universal Power Supply and Plug Adaptors Acessory Pouch

USB Flash Drive Pre-Loaded with Report Generang Worksheet

12

3

Doc# 100928 • HI-903-Shaker • October 2017-RevA Page 3 of 33

2. BASIC OPERATION

For the basic operaon of the HI-903, a vibraon sensor and appropriate cable

are needed. Typically the HI-903 is used as a vibraon excitaon source and as a

readout device with the vibraon sensor connected to the HI-903’s Test Sensor BNC

Input. Alternavely, the HI-903 unit can be used to test dierent types of vibraon

equipment (i.e. a vibraon meter or vibraon monitoring system), in which case

the sensor will be directly connected to the vibraon measurement equipment and

the HI-903 is used just as a controlled excitaon source.

Test Setup

1. Mount your sensor to the HI-903 mounng plaorm

• The HI-903 sensor mounng plaorm is threaded for a ¼-28 stud. Select

an appropriate adaptor for mounng the sensor.

• While ghtening the sensor, secure the HI-903 mounng plaorm with

the supplied wrench to prevent damage from torque

2. Connect sensor under test (SUT) to “Test Sensor In.” Make sure that

connecons are secure.

3. Power the unit ON by pressing and holding the FREQUENCY dial for 3 seconds.

NOTE: It is good pracce to perform calibraons on baery power. Disconnecng

from line power ensures a power surge will not cause the calibrator to power down

during test. If excess current is detected during use, the portable calibrator shuts

down to prevent damage.

Selecng Input Mode

4. The HI-903 can accept ICP® as well as AC voltage and AC current output

sensors. Press and hold the AMPLITUDE dial to select between ICP®, Voltage Mode

or Modulated Current mode. Modulated Current mode is only available if the 9110-

MC rmware opon is ordered, otherwise user will not see this mode as an opon.

Note: ICP® (or IEPE) mode sensors are the most popular type of accelerometer

transducers and require a 2 mA to 20 mA constant current supply to operate.

The HI-903 unit supplies the necessary constant current to power this class of

sensors. Voltage output sensors are typically moving coil velocity sensors but

can also be the voltage output of a signal condioner associated with any type

of vibraon transducer such as the output from the probe driver in a proximity

probe system. Refer to the Sensor Signal Measurement Electronics (SUT Input

Characteriscs and Consideraons) for details.

Seng the Frequency and Amplitude Units

5. Select the correct Frequency Units for your test by pressing the FREQUENCY

dial to enter into the CALIBRATION OPTIONS menu:

• Use the FREQUENCY dial to highlight TEST SETTINGS then press.

• Within the Test Sengs Menu rotate the FREQUENCY dial to

highlight FREQUENCY UNIT then press to toggle between Hertz and

CPM.

6. Select the correct Amplitude Units for your test by pressing and releasing the

AMPLITUDE dial. The following opons are available:

Doc# 100928 • HI-903-Shaker • October 2017-RevA Page 4 of 33

Acceleraon Velocity Displacement

g’s pk

g’s RMS

m/s2 pk

m/s2 RMS

in/s pk

in/s RMS

mm/s pk

mm/s RMS

mils p-p

µm p-p

7. Select the desired vibraon amplitude and frequency for tesng by turning the

AMPLITUDE and FREQUENCY dials clockwise to increase or counter clockwise to

decrease the seng.

•Slow Turns – sengs will increase or decrease by single steps

•Fast Turns – sengs will increase or decrease by larger increments

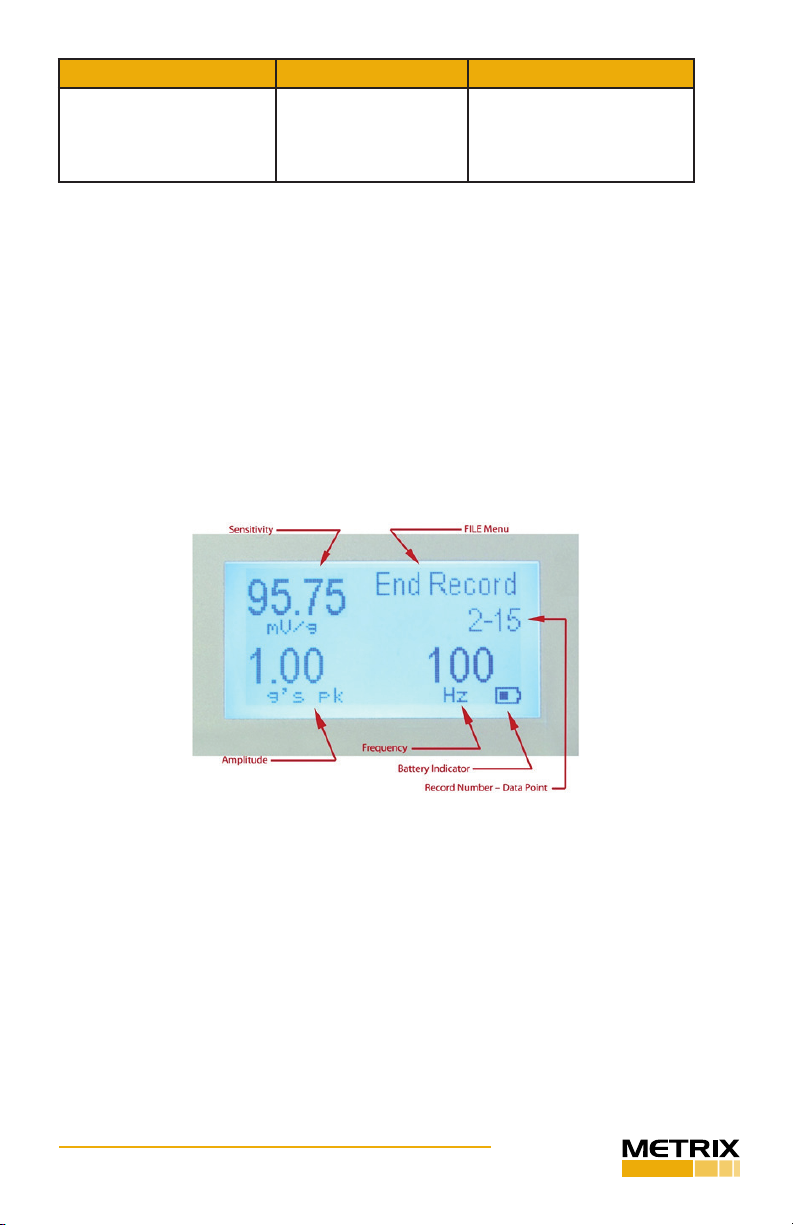

Record and Save Calibraon Points

8. Once the frequency and amplitude are set to desired values, with the le

menu set to “Save Point,” press the FILE dial to store the calibraon data point.

9. Repeat steps 7 through 9 to set the frequency and amplitude to increment to

the next calibraon data point and save.

Compleng and Storing Record to Memory

10. Once all data points have been saved in a record and record is complete, rotate

FILE dial and press it to select “End Record.”

• The screen will prompt with:

11. Rotate the FILE dial to “Edit” to enter the model number, serial number and

axis. The FILE menu for this screen also includes the tools “Next” and “Back.”

• Push the FILE dial to choose “Next,” which goes to the next save

screen.

12. To “Save” the record without inpung an annotaon, press the FILE dial two

more mes.

13. Rotate the FILE dial to “Edit” and press to store any annotaons or addional

notes (such as technician inials, etc):

• Turn the FILE dial to the le and right to select each individual leer

or number you wish to input as part of an annotaon. Push the FILE

dial to save each character.

• Rotate the FILE dial and select “Save.” This will save all data points in

the listed record number. The record number shown on the screen

increments automacally.

Doc# 100928 • HI-903-Shaker • October 2017-RevA Page 5 of 33

Transfer Records to USB Flash Drive

14. Rotate FILE dial and press to select “Tools.”

15. Rotate FILE dial and press to select “USB Menu.”

• A USB ash drive must be connected to the unit. The USB must be

formaed to FAT32. You can use the HI-903 or a PC to format the

ash drive.

16. To copy all data points and records to a USB Flash Drive, rotate FILE dial and

press to select “Copy All Records.”

• This will leave current records on unit memory and also create a

copy on the USB.

17. To move all data points and records to USB, rotate FILE dial and press to select

“Move All Records.”

• This will remove current records on unit memory and move onto the

USB.

Note: The USB hardware may not always recognize a USB ash drive if it is plugged

into the USB port while the HI-903 is in sleep mode. Metrix recommends connecng

the USB drive while the HI-903 is on and operaonal.

Powering O

18. Suggested Best Pracce: Before powering the unit OFF, reduce the vibraon

amplitude. The HI-903 retains the sengs used prior to shutdown when it

is powered back ON. Reducing the amplitude prior to shutdown ensures the

sensor under test will not be jarred when the HI-903 is powered ON.

19. Power the unit OFF by pressing and holding the FREQUENCY dial for

approximately 3 seconds.

• To preserve baery charge, the HI-903 will automacally power o

aer 20 minutes of inacvity when not plugged in to the charger.

Aer Tesng

20. Suggested Best Pracce: Plug the HI-903 into an AC power source when not in

use. This will ensure the baeries are fully charged for your next test and also

help to maximize the lifespan of the baeries.

21. Periodic calibraon checks are recommended:

• A dedicated “vericaon sensor” can be used to check the system

readings and results. By using a dedicated sensor, you can ensure

that the system is providing the same result during each test. Metrix

oers Model 9105D for this purpose. (The 9105D includes a transfer

standard reference accelerometer and ICP sensor signal condioner,

for system vericaon of portable vibraon calibrators).

• The HI-903 should be returned to Metrix for regular recalibraon

(recommended annually - Service Code 9100-CAL01) or for any

maintenance or repair. The most current factory calibraon date or

the calibraon due date is displayed on the LCD screen during the

HI-903 boot up sequence. The default due date is set for 12 months

aer the last factory calibraon, but the calibraon interval can be

user dened to be anywhere from 1 to 72 months, or set up to never

expire.

• NOTE: The aforemenoned Model 9105D allows users to duplicate

Metrix’s calibraon process without returning the shaker to the

factory.

Doc# 100928 • HI-903-Shaker • October 2017-RevA Page 6 of 33

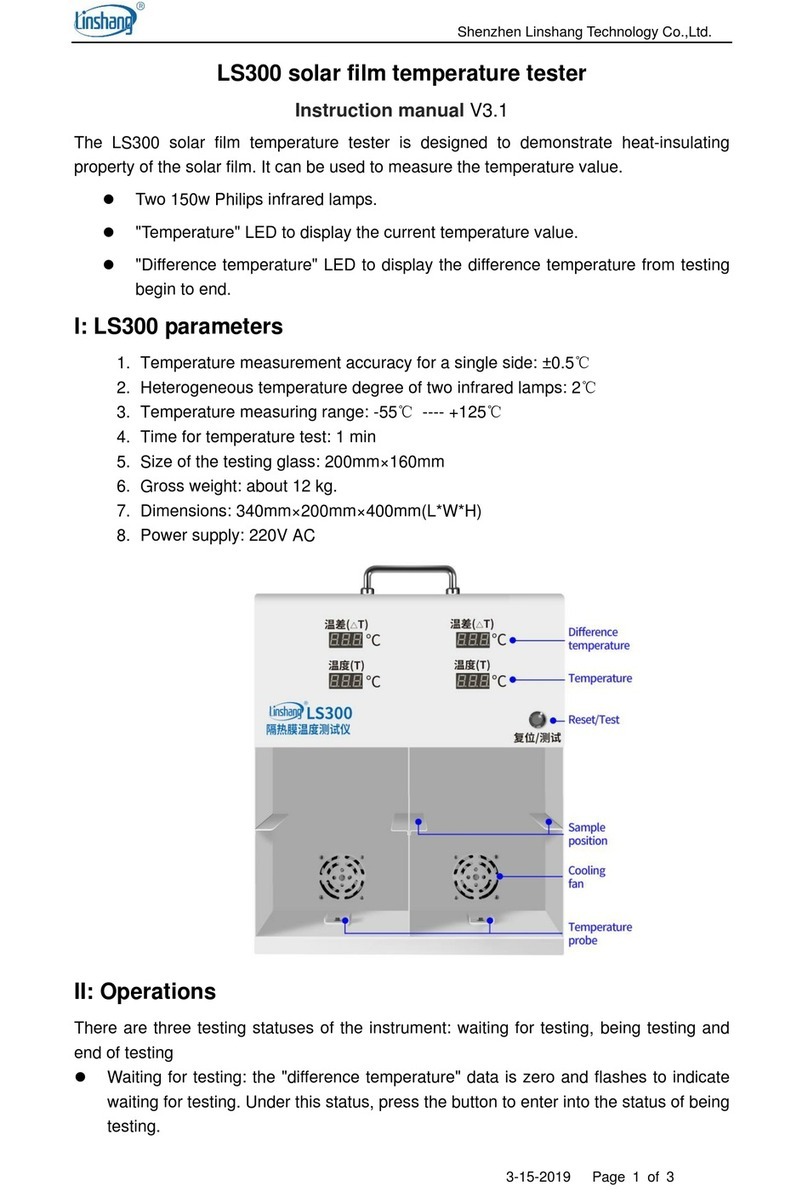

Report Generaon Workbook

Calibraon data can be saved into the HI-903’s internal memory and easily

exported to a personal computer using a USB Flash Drive.

The HI-903 Portable Vibraon Calibrator includes a pre-formaed USB Flash

Drive with a Microso Excel Report Generaon Workbook for the creaon of

customizable calibraon cercates. The Excel le provides an intuive interface

which allows a user to create and print a calibraon cercate with just a few

mouse clicks. In order to use the le, make sure macros are enabled, otherwise

Excel won’t be able to load data and create the cercates.

The Excel workbook consists of the following worksheets or tabs:

• FRData – Use this tab to create a frequency response cercates in just 2

steps:

1. Clicking on Import Data from File buon prompts the user to select and import

a .pvc calibraon data le previously created by the HI-903

2. Once data is loaded into the table, click View Cercate to see and print a

calibraon cercate containing the frequency response data (the reference

frequency for the calibraon cercate is 100Hz and can be changed by the

user as needed)

Note: If tesng a charge-mode accelerometer and calibraon cercate

in pC units is desired, click the box at top le of the FRData tab and enter

the sensivity of the charge amplier in the “mV/pC” box located at cell

D8. See the secon “Calibrang Charge-Mode Accelerometers” for more

informaon.

• LINData – Use this tab to create linearity response cercates. The worksheet

applies linear regression to interpolate the data. The Max Linearity is calculated

for the worst deviaon of a parcular point from the best-t straight line (BFSL)

of all tested points. The table also displays the specic results at each test level.

The LINData worksheet has 2 tables. The le table should be used for creang

dynamic linearity data calibraon cercates in just 2 steps:

1. Click on Import Data from File to select and import a .pvc calibraon data le

previously created by the HI-903

2. Once data is loaded into the table, click View Cercate to see and print a

calibraon cercate containing the linearity response data. The worksheet

expects the data points to be taken at the same frequency (speed). A checkbox

opon labeled Set Y-intercept to zero is available to force the interpolaon to

go through the origin point.

The right table in the LINData worksheet is used to create a DC proximity probe

curve or linearity cercate for 4-20 mA vibraon transmier. Creang a DC

proximity probe curve requires the proximity probe adaptor kits and a DC

voltmeter (not included). Creang a linearity cercate for a 4-20 mA vibraon

transmier requires DMM set to DC current input. A 24 VDC power supply may

also be needed:

1. Select the appropriate vibraon scale (Acceleraon, Velocity or Displacement)

by clicking in cell H12 and selecng from drop down menu.

2. Select the appropriate units (g’s pk, g’s RMS, m/sec2 pk, m/sec2 RMS, in/sec pk,

in/sec RMS, mm/sec pk, mm/sec RMS, mils p-p or µm p-p) in cell H13. Make

sure cell H12 is set to the right scale rst.

3. Enter known amplitude and output for the rst test point next to “Starng

Point” and repeat for each addional test point moving down the table.

Once data is entered into the table, click View Cercate to see and print a

calibraon cercate containing the linearity response data.

• FRCert - Displays the frequency response calibraon cercate using the

Doc# 100928 • HI-903-Shaker • October 2017-RevA Page 7 of 33

current data and informaon from FRData.

• LINCert - Displays the linearity response calibraon cercate using dynamic

linearity data from LINData.

• SLINCert - Displays the linearity response calibraon cercate using stac

linearity data from LINData.

• Route Creator – If rmware opon HI-903 CALROUTE is ordered, this tab can

be used to create semi-automated tests with instant pass/fail nocaon for

almost any vibraon sensor. See “Calibraon Route” for more informaon.

Addional Features

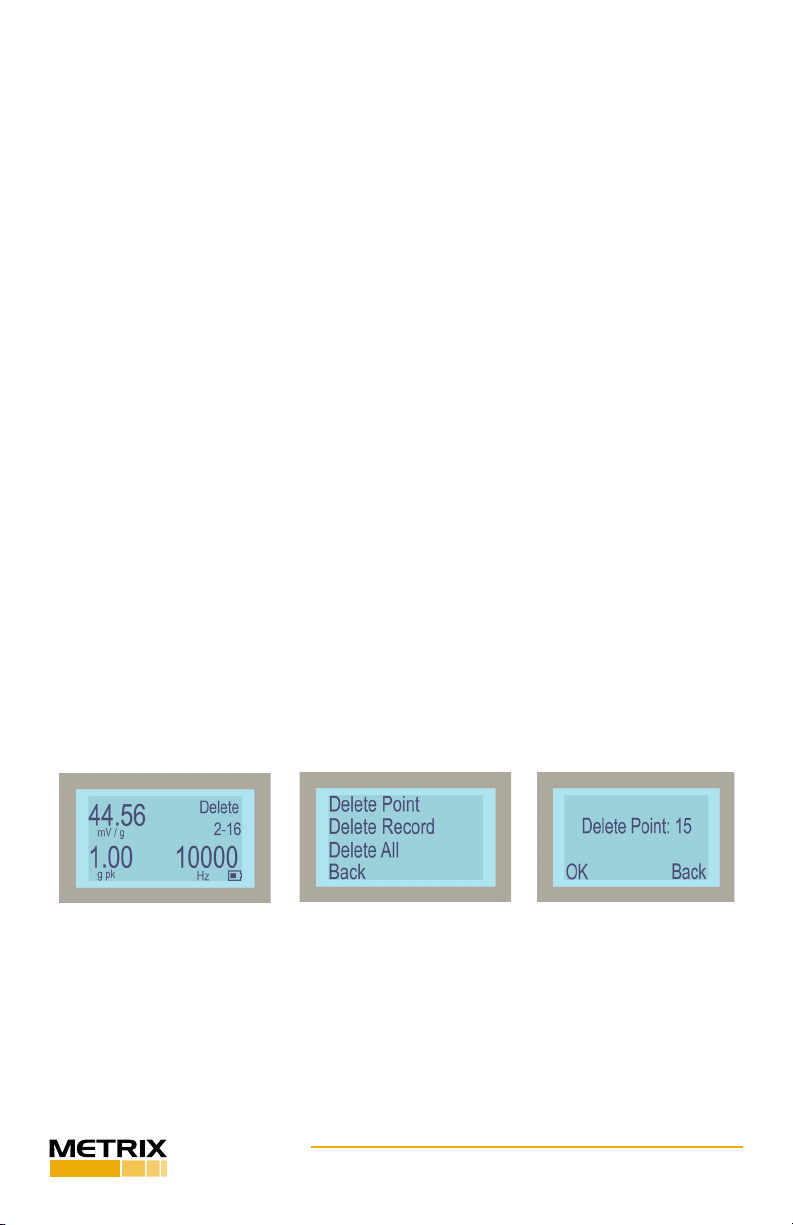

Delete

The “Delete” feature can be found under the FILE dial > “Delete.” When “Delete” is

selected, the shaker will stop moving and four opons will appear:

1. “Delete Point” will delete a current point.

2. “Delete Record” will delete the enre current record.

3. “Delete All” will delete all data points and all records that are stored on the

internal unit memory.

4. “Back” will return to the main screen.

USB Opons

The “USB Opons” feature can be found under the FILE dial > “Tools” > “USB

Menu” > “USB Opons.” When “USB Opons” is selected, the following

informaon will appear on the screen:

• “Status” – USB ash drive connected or not connected.

• “Paron” – Format of USB ash drive connected to the unit.

• “Available” – Memory space available on USB ash drive.

• “Required” – Space required to save all records on USB ash drive.

And the following acons are available:

• “Eject Drive” will safely eject the USB ash drive from the unit.

• “Format USB” for formang the USB ash drive. (FAT32 paron)

• “Back” to go back to the USB Menu.

Date and Time

The “Date and Time” feature can be found under the FILE dial > “Tools” > “Opons”

> “Date and Time.”

1. Press the FILE dial to select “Adjust.”

2. Turn the AMPLITUDE dial to the select the current month, day and year and

push the FREQUENCY dial to conrm or the AMPLITUDE dial to change.

3. Press the AMPLITUDE dial to select “yes” this is correct.

4. Turn the AMPLITUDE dial to select the current hours and minutes then push

the FREQUENCY dial to conrm the me is correct.

5. Press the AMPLITUDE dial to select “yes” this is correct.

Calibraon Interval

The “Calibraon Interval” can be adjusted under the FILE dial > “Tools” > “Opons”

> “Calibraon Interval.”

1. Select “Adjust” and press FILE dial.

2. Turn AMPLITUDE dial to select number of months for Calibraon Interval.

• Suggested Best Pracce: 12 months. The calibraon interval can be

dened to be anywhere from 1 to 72 months, or set up to never expire.

3. Press FREQUENCY dial to conrm selected Calibraon Interval.

Doc# 100928 • HI-903-Shaker • October 2017-RevA Page 8 of 33

Traceability

The “Traceability” feature can be found under FILE dial > “Tools.”

1. Press FILE dial to select “Traceability.” A screen with the following informaon

will appear:

• Model

• Serial Number

• Firmware Revision Number

• Calibraon Date

• Reference Sensor Sensivity

• PRD-P

• NIST Traceability Number

• PTB Traceability Number

2. Press FILE dial to go back to main screen and shaker will go back to shaking.

Test Sengs

The “Test Sengs” menu can be found by pressing FREQUENCY dial > “Test

Sengs.” A screen with the following will appear, use the FREQUENCY dial to

highlight and toggle all sengs:

• Back – returns user to “Calibraon Opons” menu

• Cal Route: N/A, Acve or o

o N/A indicates the Calibraon Route rmware opon has not

been purchased. Calibraon Route allows users to program semi-

automated test points with instant pass/fail nocaon. See

“Calibraon Route” secon for more informaon. Contact Metrix

to unlock this feature.

• Source: Internal or External

o If external is selected the shaker can be controlled with an external

source. See “Input/Output” for more informaon.

• Frequency Unit: Hertz or CPM (cycles per minute)

• Sensor Type: ICP®, Voltage or Modulated Current

o Use ICP® for most accelerometers, Voltage for proximity probes

and moving coil sensors, Modulated Current for high-temp turbine

vibraon sensors with AC current output. See “Selecng the Input

Mode” for more informaon. Modulated current is oponal;

contact Metrix to unlock this feature.

• Sensor Readout: mV/EU or mV

o Changes the display to show the sensor under test’s sensivity

(output voltage divided by input vibraon, mV/EU) or the sensor

under test’s raw AC output voltage.

Amplitude Units

Amplitude units that are seldom or never used can be turned o by using the

“Amplitude Units” feature, found by pressing FREQUENCY dial > “Amplitude Units.”

The “Amplitude Unit Screen” shows all 10 available amplitude scales on model

HI-903 Portable Vibraon Calibrator. Use the FREQUENCY dial to highlight each

scale and press the dial to toggle the scale on or o. A lled circle next to the

scale indicates it is acve. An empty circle next to the scale indicates it is inacve.

Inacve scales do not appear when cycling through scales using the AMPLITUDE

dial during normal operaon.

Doc# 100928 • HI-903-Shaker • October 2017-RevA Page 9 of 33

To go back to the “Calibraon Opons” menu use the FREQUENCY dial to highlight

“Back” then press.

Calibraon Route

Firmware Opon: HI-903 CALROUTE

Model HI-903 must be ordered with rmware opon 9110-CALROUTE for the

Calibraon Route features to be available. This rmware can be added at any me.

Contact Metrix for ordering and installaon informaon.

The Calibraon Route rmware allows users to create and run semi-automated

frequency response and amplitude linearity tests for vibraon sensors on model HI-

903 with instant pass/fail nocaon. Tests or “routes” are created in the Report

Generaon Workbook then uploaded to the HI-903 via supplied USB drive. Once

uploaded the test is acvated. But the test can also be de-acvated at any me,

pung the HI-903 back into manual operaon mode. When a Calibraon Route

is acve the HI-903 can only adjust to the pre-dened amplitude and frequency

points that have been programmed.

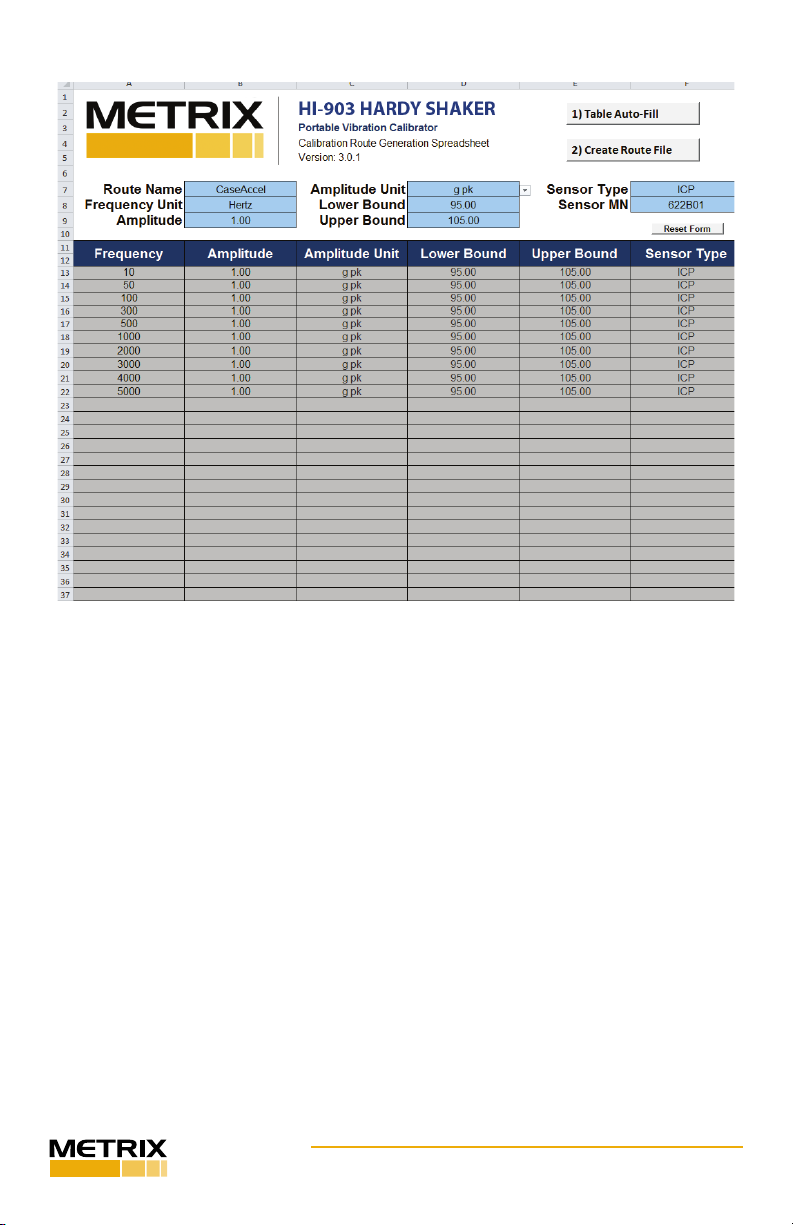

Creang A New Test (Route)

Version 2010 or later of Microso Excel® is required for the CalRoute features

in Report Generaon Workbook to operate correctly. Drop-down arrows for

frequency and amplitude units may not appear if using older versions of this

soware.

1. Open the Report Generaon Workbook (version 3.0.2 or later required)

using Microso Excel®

2. At boom, select the Route Creator tab

3. Route Name: Enter the name of the test in cell B7 next to “Route Name”.

When the test le is created and saved the le name will be this value

followed by “_Route.pvc”.

4. Frequency Unit: Use the drop down arrow to choose the frequency unit

(Hertz or CPM) in cell B8. One cannot toggle between Hertz and CPM

during the test.

5. Amplitude Unit: Use the drop down arrow to choose the amplitude unit

(g pk, g RMS, m/sec2 pk, m/sec2 RMS, in/sec pk, in/sec RMS, mm/sec pk,

mm/sec RMS, mils p-p or µm p-p) in cell D7.

6. Amplitude: If desired, enter the amplitude for all test points in cell B9 next

to “Amplitude”. This is useful for a frequency response test where all test

points will have the same amplitude value. If creang a linearity test leave

this cell blank since the amplitude values will change for each test point.

Doc# 100928 • HI-903-Shaker • October 2017-RevA Page 10 of 33

7. Sensor Type: Use the drop down arrow in cell F7 to select the sensor type

(ICP®, Voltage or Modulated Current).

8. Sensor MN: if desired, enter the sensor model number in cell F8. This

is oponal. The sensor model number that is entered will print on the

calibraon cercate. It can be changed at any me. If the model number

is not consistent leave this cell blank.

9. Lower Bound: in cell D8 enter the minimum sensivity value for the

sensor under test at each test point that will pass calibraon test. For

example, the minimum acceptable sensivity for 100 mV/g accelerometer

with +/- 5% sensivity tolerance is 95 mV/g, thus lower bound would be:

95.00.

10. Upper Bound: in cell D9 enter the maximum sensivity value for the

sensor under test at each test point that will pass calibraon test. For

example, the maximum acceptable sensivity for 100 mV/g accelerometer

with +/- 5% sensivity tolerance is 105 mV/g, thus upper bound would be:

105.00.

11. Press Table Auto-Fill. The grey cells in the table will automacally

populate with the values chosen in steps 3-10. All cells will populate. The

table is capable of creang a 30-point test. But any number of test points

can be programmed. Before creang the route le user must delete values

in cells for test points that should not be created (see example).

12. Enter the desired Frequency values for each test point in column A

beginning with cell A13. The test will be conducted in the exact order as

programmed. The rst test point will be as programmed in row 13; the

next will use row 14 values and so on.

a. The HI-903 can only simulate vibraon in CPM values that are

mulples of 60. I.e. 1800 CPM, 3600 CPM, 4200 CPM, etc. If a

value is entered that is not a mulple of 60, the HI-903 will adjust

down to the nearest CPM value that is a mulple of 60.

b. Example: 1900 CPM is entered as a test point. The HI-903 will

adjust to 1860 CPM and 1860 CPM will be displayed.

13. Enter the desired Amplitude values for each test point in column B

beginning with cell B13. Skip this step if all amplitude values have been

automacally populated using the Table Auto-Fill buon.

14. Modify any individual test point as desired. For example, most

accelerometers have a wider sensivity tolerance at extreme low and high

frequencies. User may wish to expand the upper and lower bounds for

certain test points.

15. Delete undesired test points. For example, a 10-point test only requires

rows 13-22. The Table Auto-Fill feature saves typing but one must delete

data from cells that are not needed. For a 10-point test rows 23-42 should

be blank thus they can be highlighted and cleared.

16.Press Create Route File. A .pvc le will be created, save this le to the USB

drive in the Calibraon_Route folder.

a. When prompted to save, open the USB Disk

b. Open the METRIX_PVC folder

c. Open the Calibraon_Route folder

d. Press save

Doc# 100928 • HI-903-Shaker • October 2017-RevA Page 11 of 33

Example Accelerometer Test (Route)

An example of a 10-point accelerometer test, created in the Report Generaon

Workbook, is shown above. Some helpful notes…

• When run, this test will shake the accelerometer at 1g pk at all points. If

the shaker cannot generate 1g pk it will output the maximum vibraon

possible given the sensor’s weight and test speed. The shaker will not

allow user to program points that can damage the shaker.

• The test will begin at 10 Hz and end at 5000 Hz, with test points at

50,100, 300, 500, 1000, 2000, 3000 and 4000 Hz as well.

• If the sensor under test’s sensivity is above 105 mV/g or below 95 mV/g

the HI-903 will alert the user that test point failed.

• The le name will be CaseAccel_Route.pvc, when uploading to the HI-903

one would choose this le.

• ICP® power is acve for all test points. If this test were applied to a self-

powered sensor data would be invalid. One would select “Voltage” for a

self-powered sensor such as a moving coil velocity transducer.

Doc# 100928 • HI-903-Shaker • October 2017-RevA Page 12 of 33

Example Proximity Probe Test (Route)

An example of a 10-point proximity probe test, created in the Report Generaon

Workbook, is shown above. Some helpful notes…

• This test will simulate vibraon at 3600 CPM for all test points.

• This is a linearity test. Vibraon will start at 1.0 mils p-p and escalate to

10.0 mils p-p. The sensor will be evaluated every 1.0 mils.

• The test is designed for a 200 mV/mil proximity probe with 5% tolerance.

Thus sensivity of 190-210 mV/mil passes calibraon. If outside those

values the HI-903 will indicate the test point has failed.

• The sensor type is voltage. This means ICP® power is turned o. The

proximity probe is being powered by its probe driver. To run this test the

technician must connect the output of the probe drive to “Test Sensor In”

on the HI-903.

• The name of the le will be ProxProbe_Route.pvc.

• The model number 330101 will print on each test report created using

this route. It can be modied on the cercate if desired to add thread

lengths, cable length, etc.

Loading & Acvang a Calibraon Test (Route)

With the calibraon test saved as a .pvc le to the Calibraon_Route folder on the

USB and the USB inserted into the port on the HI-903 the following instrucons

detail how to upload to model HI-903 and acvate:

1. Press the FREQUENCY dial to enter “Calibraon Opons” menu, rotate to

highlight TEST SETTINGS and press again to enter “Test Sengs” menu.

2. Use FREQUENCY dial to highlight and click selecon next to “Cal Route:”.

Selecon will be “O” or “Acve” depending upon previous status. When

clicked user will enter into “Route Opon” menu.

a. If display indicates “Cal Route: n/a” the HI-903-CALROUTE

rmware has not been purchased. Contact Metrix to add this

rmware to the HI-903.

3. Use FREQUENCY dial to highlight and click on LOAD FILE FROM USB

4. Up to six route les (tests) are shown. Use FREQUENCY dial to highlight

and click on desired le.

Doc# 100928 • HI-903-Shaker • October 2017-RevA Page 13 of 33

5. Display will indicate “Route Load Successful Acvate Now?” To acvate

press the AMPLITUDE dial.

a.To load to memory but not acvate the test press FREQUENCY.

The calibraon test is now loaded and acve. Rotang the FREQUENCY dial allows

user to scroll through programmed test points without saving data.

Execung the Semi-Automated Calibraon Test (Route)

The calibraon test has been created and saved to the USB. It has also been

uploaded and acvated in the HI-903 using the previous secon. The following

instrucons detail usage of the HI-903 while the pre-programmed test is acve. To

use the HI-903 in manual mode again the calibraon route must be de-acvated

(see next secon).

• With a Calibraon Route acve the HI-903 will only cycle to the pre-

programmed test points. The FREQUENCY dial can be used to cycle and

preview test points without saving data.

• Pressing the amplitude dial will not change amplitude scales while route is

acve.

• Data is sll stored to internal memory when Calibraon Route is acve if

FILE dial is pressed while “Save Point” is displayed. Delete, Save, Tools and

End Record funcons operate as previously detailed in “Basic Operaon”

secon.

1. Once the Calibraon Route is acvated shaker will vibrate at rst pre-

programmed test point. Use FILE dial to display “Save Point” then press

the dial.

2. A pass/fail indicaon is displayed. The frequency, amplitude, sensivity

of sensor under test, upper and lower bounds are shown. If sensivity

is between upper and lower bounds “Pass” is shown at top right. If

sensivity is outside of bounds “Fail” is displayed. Press FILE dial to

connue to next test point.

a. If test point fails technician can delete the point and try again

by using FILE dial to display “Delete” then press and make

appropriate selecon. Deleng the point will step the test back

to the previously failed test point.

3. Connue the test point-by-point by pressing the FILE dial with “Save

Point” displayed. The pass/fail screen will appear aer each point.

4. When test is complete the model and serial number entry screen is

displayed. Enter data as outlined in “Basic Operaon” secon or skip by

pressing FILE with “Next” displayed.

5. A nal data entry screen is displayed, with “Save” displayed press FILE to

save the calibraon test results to internal memory and begin next test.

Doc# 100928 • HI-903-Shaker • October 2017-RevA Page 14 of 33

Creaon of print-able test reports is done as previously menoned. Follow

instrucons in “Basic Operaon” secon to create frequency response and linearity

calibraon cercates in Microso Excel®.

Route Opon Menu

The Route Opon menu is accessed by pressing FREQUENCY dial then using the

dial to highlight and click on Test Sengs, then using the dial to highlight the text

next to Cal Route: and clicking on it. The menu has the following funconality and

the FREQUENCY dial is used to navigate and select:

• Back – returns to Test Sengs menu

• Acvate Route – acvates the calibraon test stored in memory

• Deacvate Route – returns the HI-903 to manual operaon, de-acvates

semi-automated test

• Load File From USB – shows a list of up to six pre-programmed tests

(routes) read from Calibraon_Route folder on USB drive

• Delete Route – returns the HI-903 to manual operaon and also deletes

the pre-programmed test from memory

• File Informaon – displays name of semi-automated test, number of test

points and date it was created. If no test is acve pressing le while this

opon is highlighted does nothing.

• Eject USB – allows user to safely remove the USB drive from HI-903

Denion of Frequency Units

• Hertz (Hz) is dened as the number of periodic cycles per second and it is

a standard unit for measuring signal frequency.

• CPM stands for Cycles Per Minute. CPM is commonly used for tesng

industrial sensors that monitor rotaonal vibraon. 1 Hz=60 CPM

Denion of Amplitude Units

• Root Mean Square (RMS) is a calculaon that takes the square root of

the average of the squared amplitudes from a set of data. This type of

measurement takes all amplitudes of a signal into account rather than just

one, making it an accurate tool for an overall calculaon.

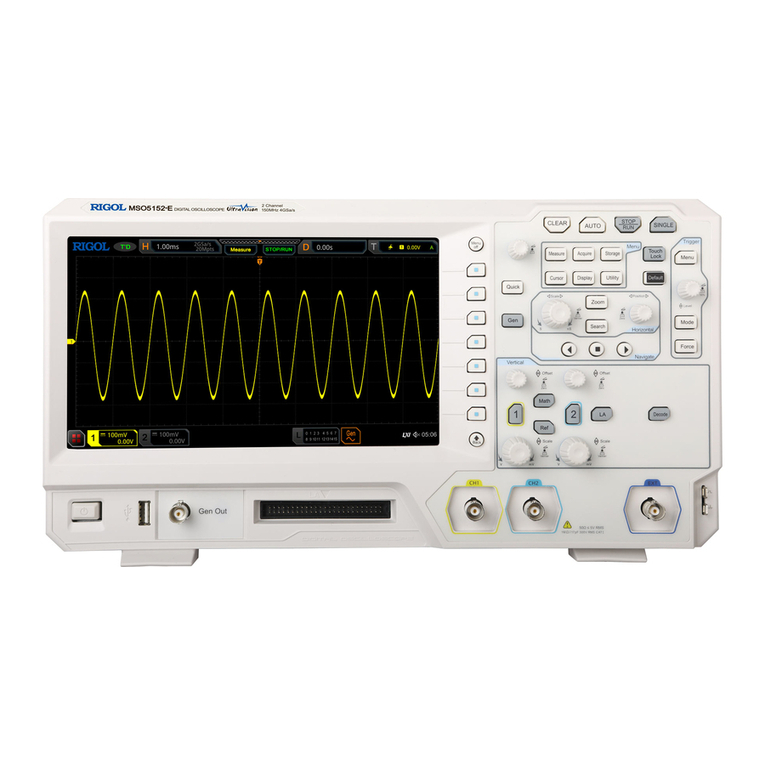

• Peak (pk) bases calculaons on the highest value of the signal generated

during tesng. For a sinusoidal wave (as is produced by the HI-903), the

peak value is calculated by RMS* . The HI-903 does not measure a true

Figure: Sinusoidal Wave

Doc# 100928 • HI-903-Shaker • October 2017-RevA Page 15 of 33

peak value, but instead esmates the value mathemacally based upon

the RMS value.

• Peak to Peak (p-p) is a calculaon of the dierence between the highest

posive peak and the lowest negave peak of a recorded sine wave. The

p-p value is calculated as two mes the peak value.

• Gravitaonal acceleraon (g) is the acceleraon experienced naturally by

objects in earth’s gravitaonal eld. It is approximately equal to

9.80665 m/s2.

Mounng Basics

Connecng Sensor to HI-903 Plaorm

1. Mang surfaces of the mounng plaorm and sensor should be at,

parallel and free of dirt, paint, epoxy, scratches, etc.

2. Threads in plaorm, sensor and adaptor (if needed) must match to ensure

a proper t and that tesng is free of errors. Clean any worn threads with

a tap or die and coat them in silicone grease for best results.

3. An adaptor may be needed to connect the sensor to the armature. The

HI-903 plaorm requires a ¼-28 thread.

4. Silicone grease can be applied to the mang surfaces and threads to

ensure good mechanical coupling. This is parcularly important when

tesng at high frequencies.

5. For threaded sensors, please follow the sensor manufacturer’s torque

recommendaon.

Tightening and Loosening Connecons

1. When ghtening or loosening the connecon between the sensor and

the HI-903 mounng plaorm, secure the mounng plaorm with the

supplied wrench.

2. It is important to keep sensors and xtures centered and straight when

aaching them to the HI-903 mounng plaorm. This will ensure a stable,

even connecon and eliminate potenal alignment issues.

Input / Output

EXTERNAL SOURCE IN Input BNC

It is possible to drive the HI-903 by using an external signal source or a funcon

generator. First, connect a signal source to the EXTERNAL SOURCE IN BNC Input

located on the top le corner of the unit. To enable the EXTERNAL SOURCE

IN input, press the FREQUENCY dial to enter the “Calibraon Opons” menu

then rotate FREQUENCY dial to highlight and click on TEST SETTINGS. Next, use

FREQUENCY dial to highlight selecon next to “Source:” and toggle between

“Internal” and “External” by pressing the dial, select “External”.

1. When in Ext Sig mode, the vibraon amplitude is measured and displayed on

the screen, however, the frequency and amplitude of the shaker is controlled by

the external source, not by the HI-903. The frequency of the input signal is not

displayed on this mode.

2. The amplitude and sensivity values displayed on the screen are for reference

only. The measurements are not accurate while in Ext Sig mode and do not fall

under the published specicaons for the product.

Doc# 100928 • HI-903-Shaker • October 2017-RevA Page 16 of 33

Do not exceed 1V RMS! Overdriving the unit may cause clipping,

unwanted distoron and damage to the unit

MONITOR REFERENCE OUT Output BNC

The HI-903 is controlled by an internal shear mode quartz reference accelerometer.

The voltage output of the reference accelerometer can be monitored through the

available MONITOR REFERENCE OUT BNC output by connecng it to a readout

device (e.g. voltmeter or oscilloscope).

Diagnosc Screen

The diagnosc screen can be displayed by holding down the le buon for

approximately 2 seconds. This screen displays informaon about the operaon of

the HI-903. The informaon found in this menu is displayed in real me:

Reference ICP Bias Voltage

Test Sensor Bias Voltage

Test Sensor Type: Voltage, ICP® or Modulated Current

Signal Type: Internal or External

Reference THD

Sensor THD

Exit the diagnosc screen by pressing the le buon.

TEST SENSOR IN Input BNC

The HI-903 provides the capability to measure the test sensor’s voltage signal,

replacing the need for an external DMM or data acquision. The input electronics

can be congured for Voltage, ICP® or Modulated Current mode as described in

Step 4 of Basic Operaon earlier in this manual.

The TEST SENSOR IN input BNC is capable of measuring a voltage input of up to

10V AC pk-pk. As an ICP® sensor signal condioner, it measures up to 10V pk-pk AC

signal while supplying 5mA ICP® constant current at 25V DC. While in ICP® mode,

the input circuit is also monitoring the ICP® sensor Bias Voltage and will indicate a

Bias Fault when the DC voltage is below 2V DC or above 15V DC. The open circuit

voltage of the ICP® supply will be 25V DC. This open circuit and the ICP® Bias

Voltage may be checked using the diagnosc menu.

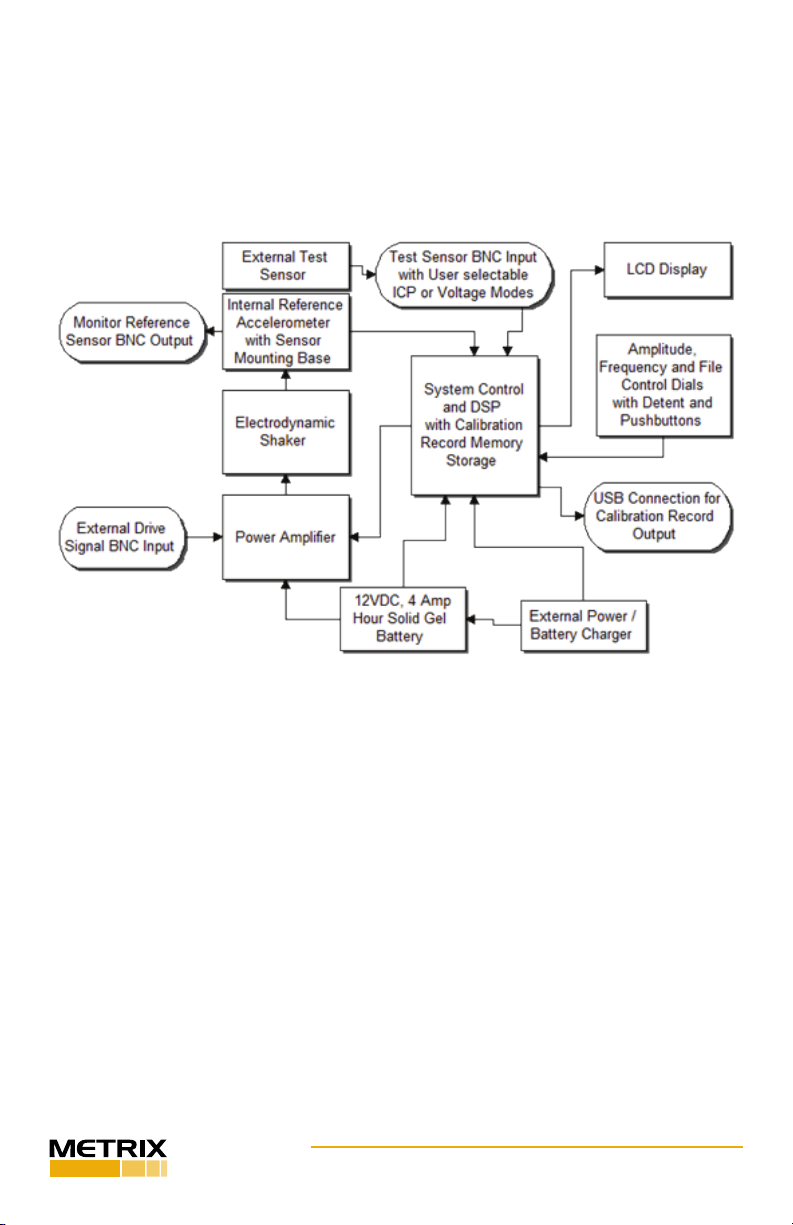

3. THEORY OF OPERATION

Instrumentaon

The Model HI-903 Portable Vibraon Calibrator internal electrical system is

comprised of several dierent mechanisms:

• Electrodynamic Shaker

• Power Amplier

• Reference Accelerometer

• Signal Generaon Electronics

• Sensor Signal Measurement Electronics

• LCD Digital Display

Doc# 100928 • HI-903-Shaker • October 2017-RevA Page 17 of 33

• 3 Dials with Detent and Integrated Pushbuons

• 12 VDC, 4 Amp Hr Solid Gel Baery

• External Charger

• Three dierent BNC ports: “External Source In,” “Monitor Reference Out” and

“Test Sensor In”

• USB Flash Drive Port

The LCD display connuously shows the frequency of the shaker drive signal and

the vibraon amplitude of the mounng plaorm as measured by the reference

accelerometer.

The reference accelerometer is a PCB Piezotronics ICP® quartz shear sensor,

integrated into the mounng plaorm. A calibraon “standard” maintained by

METRIX is used to calibrate the HI-903 as a complete system and provides NIST

traceability. Traceability informaon can be viewed under the tools menu as

described in the previous secon.

The power amplier is specically designed to provide the current required to drive

the electrodynamic shaker. The electronic signal processing system produces a

variable frequency sine wave to the power amplier, which becomes the source of

the driving signal to produce the vibraon at the mounng plaorm.

The frequency of the shaker drive signal is controlled by the front panel

FREQUENCY dial. The amplitude of the shaker drive signal is controlled through a

feedback loop, to maintain the stability of the actual moon. Adjusng the front

panel AMPLITUDE dial adjusts the target vibraon amplitude.

Pressing the AMPLITUDE dial toggles the amplitude measurement units through

the following choices if all units are acve:

Doc# 100928 • HI-903-Shaker • October 2017-RevA Page 18 of 33

Acceleraon Velocity Displacement

g’s pk

g’s RMS

m/s2 pk

m/s2 RMS

in/s pk

in/s RMS

mm/s pk

mm/s RMS

mils p-p

µm p-p

Users can de-acvate amplitude scales by using the “Amplitude Units” menu.

See the secon “Amplitude Units” for more informaon. If desired scale is not

appearing while pressing AMPLITUDE to cycle through scales, then it has likely

been turned o in the “Amplitude Units” menu.

Turning the FILE dial acvates the le menu. Turn the FILE dial to toggle between

the below opons and press the dial again to select.

Save Point End Record Delete Tools

Next

Edit

Back

Delete Point

Delete Record

Delete All

Back

USB Menu

Opons

Traceability

Back

Below are the opons to choose from when the USB Menu is selected. Turn the

FILE dial to the proper opon and press it to select.

Copy All Records Move All Records USB Opons

Eject

Format USB

Back

Below are the opons to choose from when the USB Menu is selected. Turn the

FILE dial to the proper opon and press it to select.

Date and Time Calibraon Interval Set Resistance Value

Adjust Adjust Adjust

Back Back Back

Pressing and holding the le buon will return the main calibraon screen from

any new level.

Baery and Charger

The Model HI-903 can be operated from AC line power or from its internal

rechargeable baery. When the external power supply is connected, it becomes

the primary power source, operang the unit while simultaneously charging the

baery.

Doc# 100928 • HI-903-Shaker • October 2017-RevA Page 19 of 33

NOTE: It is good pracce to perform calibraons on baery power. Disconnecng

from line power ensures a power surge will not cause the calibrator to power down

during test. If excess current is detected during use, the portable calibrator shuts

down to prevent damage.

Baery power is supplied by a sealed solid gel lead acid 12 VDC rechargeable

baery. The baery can be permanently damaged if completely drained. To

prevent damage, the HI-903 will automacally shut o when the baery power

level gets too low. Suggested Best Pracce: Keeping the baery fully charged

ensures the unit is always ready for use.

Under mild operang condions (lower mass transducers at lower test amplitudes),

a fully charged baery will allow the HI-903 to operate for up to 18 hours. The

charge life of the baery depends on both the length of use and the amount

of power (dependent upon payload, frequency and amplitude) required for a

parcular test. When tesng requires high vibraon levels, the charge life will be

shorter than during less rigorous tesng. For example, connuous tesng of 100

gram payload at 10 g pk will drain the baery charge in approximately 1 hour.

A Baery Charge Indicator is displayed on the LCD screen to approximate the unit’s

remaining charge life. Replacement baeries (Model 9100-BAT01) and power

supplies/chargers (Model Number 9100-PS01) are available from Metrix.

The HI-903 calibrators connuously monitor the state of baery charge during

operaon, storage and charging. During operaon, if the baery capacity falls

near minimum, the unit will shut o aer approximately 2 minutes of inacvity

rather than the usual 20 minutes. During storage, if the baery voltage falls near

the minimum, the unit will go into deep sleep, requiring connecon of AC power

and reset of me and date before resumpon of operaon. During charging, the

unit connuously displays charging indicaon and state of charge, depending upon

operaon level and me of charge.

Baery Informaon and Care

• The unit is delivered in a parally charged state. Fully charge unit

for 20 hours before using for the rst me. (The unit cannot be

overcharged by keeping it plugged into the power supply.)

• To recharge the unit, use only the universal power supply included.

All baeries lose energy from self-discharge over me and more

rapidly at higher temperatures. A full charge cycle can take up to 20

hours.

• If not used for a prolonged period of me, recharge every 2 months.

• Suggested Best Pracce: Charge unit fully prior to eld use. Recharge

the unit as soon as possible aer use.

Doc# 100928 • HI-903-Shaker • October 2017-RevA Page 20 of 33

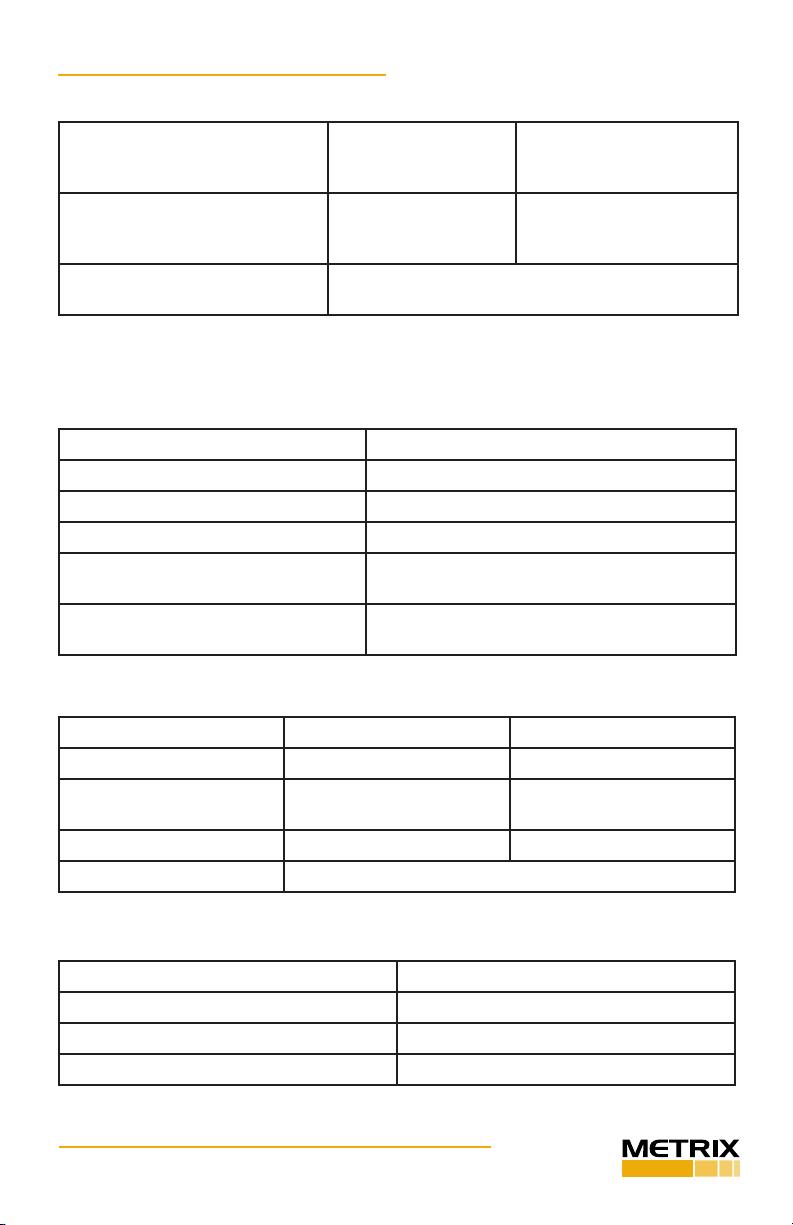

4. SPECIFICATIONS AND PERFORMANCE

General

Frequency Range (for

acceleraon)

(operang, 100 gram payload)

7 Hz - 10 kHz 420 CPM - 600k CPM

Maximum Amplitude

(100 Hz no payload)

20 g pk

15 in/s pk

50 mils pk-pk

196 m/s2 pk

380mm/s pk

1.27mm pk - pk

Maximum Payload[1] 800 gram

[1] Operang range reduced at higher payloads. Reference manual for full details

Accuracy of Readout

MEASURED WITH 10 GRAM QUARTZ REFERENCE ACCELEROMETER

Acceleraon (30 Hz to 2 kHz) ± 3%

Acceleraon (7 Hz to 10 kHz) ±1 dB

Velocity (10 Hz to 1000 Hz) ± 3%

Displacement (30 Hz to 150 Hz) ± 3%

Amplitude Linearity (100 gram

payload, 100 Hz)

< 1% up to 10 g pk

Waveform Distoron (100 gram

payload, 30 Hz to 2 kHz)

< 5% THD (typical) up to 5 g pk

Units of Readout

Acceleraon (peak/RMS) g m/s2

Velocity (peak/RMS) in/s mm/s

Displacement (peak to

peak)

mils µm

Frequency Hz CPM

Test Sensor Sensivity mV/EU[2]

[2] EU can be [g], [m/s2], [in/s], [mm/s], [mils] or [µm].

SUT Specicaons

SUT input Voltage range 10V AC pk-pk

SUT ICP current 5mA

SUT Bias oset measurement range 0-25 V DC

SUT Bias Fault Voltage limits 2V/15V DC

Other manuals for HI-903

1

Table of contents

Other Metrix Test Equipment manuals

Metrix

Metrix MX 535 User manual

Metrix

Metrix MX 604 User manual

Metrix

Metrix OX 5042 User manual

Metrix

Metrix GX 1025 User manual

Metrix

Metrix PX 110 User manual

Metrix

Metrix OX 530 User manual

Metrix

Metrix MX 407 User manual

Metrix

Metrix DOX 2 Series User manual

Metrix

Metrix OX 832 User manual

Metrix

Metrix OX 6062-II User manual

Metrix

Metrix MX 535 User manual

Metrix

Metrix MX 59HD User manual

Metrix

Metrix MX 407 User manual

Metrix

Metrix DOX3104 User manual

Metrix

Metrix MX 435D User manual

Metrix

Metrix ScopiX IV Series User manual

Metrix

Metrix HX0074 User manual

Metrix

Metrix HI-903 User manual

Metrix

Metrix HI 803 Specification sheet

Metrix

Metrix MTX 162UE TX 162UE User manual