Johnson Controls FlexSys CB2 User manual

Other Johnson Controls Controllers manuals

Johnson Controls

Johnson Controls IQ Keypad-PG User manual

Johnson Controls

Johnson Controls VA9300 User manual

Johnson Controls

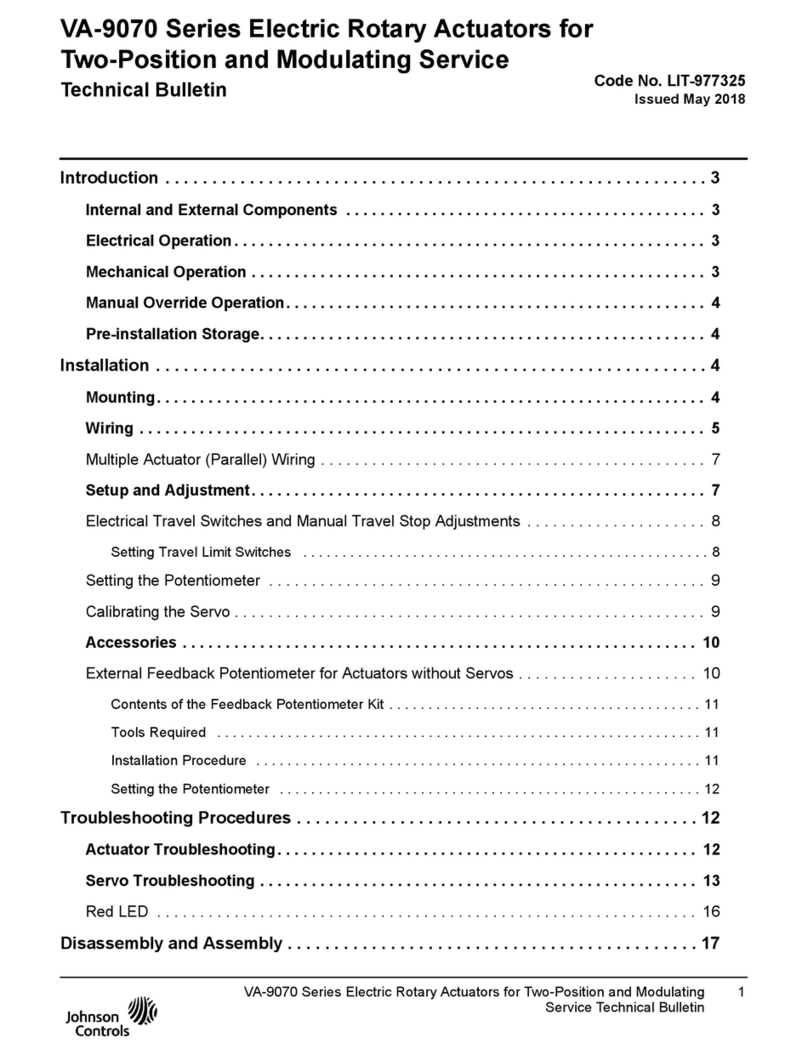

Johnson Controls VA-9070 Series Service manual

Johnson Controls

Johnson Controls tyco Power Neo HS2016 User manual

Johnson Controls

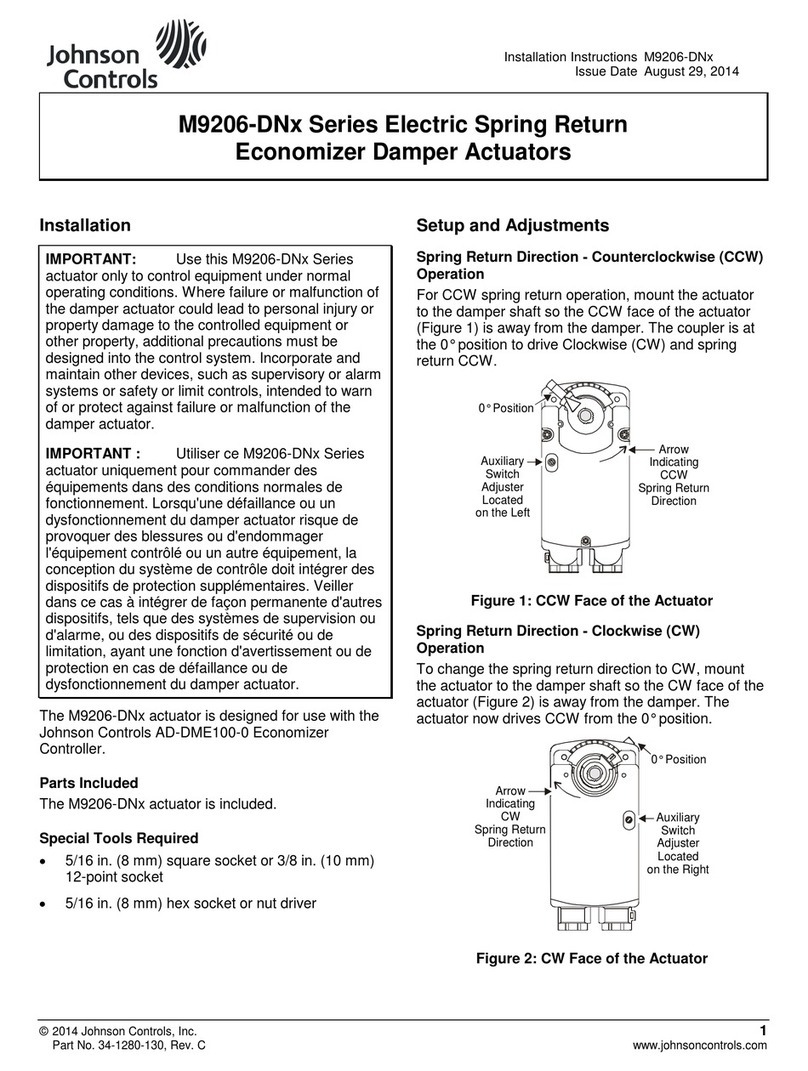

Johnson Controls M9206-DN Series User manual

Johnson Controls

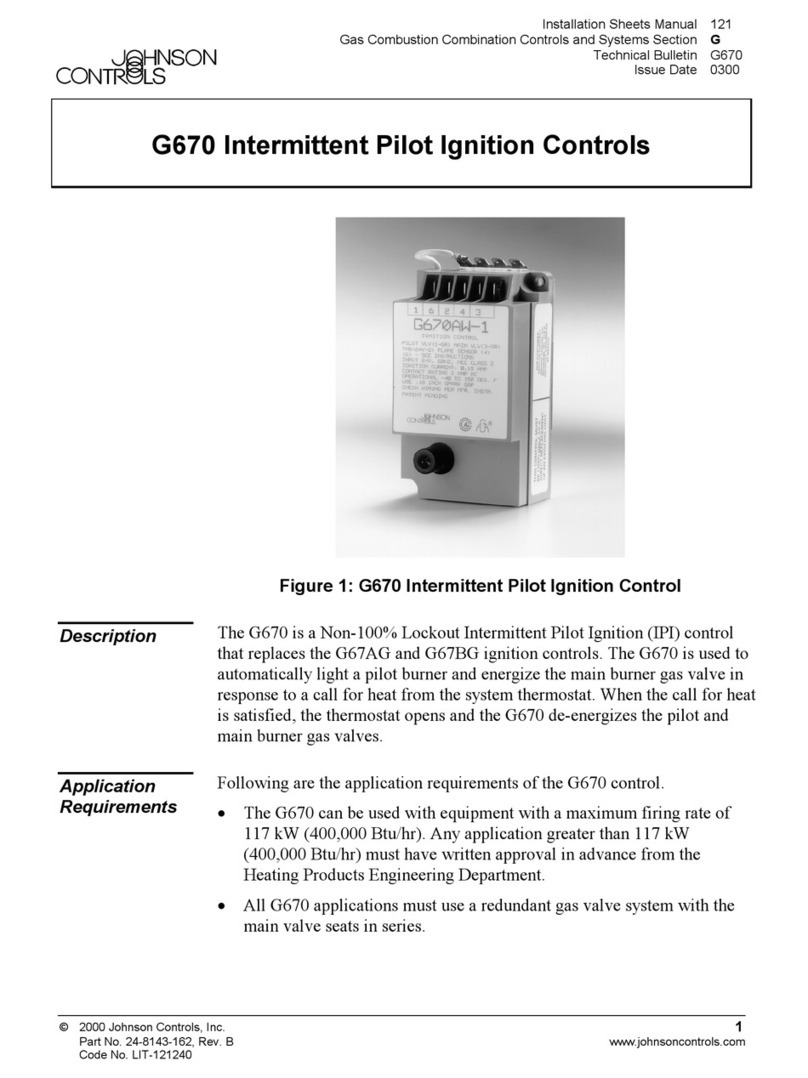

Johnson Controls G670 Assembly instructions

Johnson Controls

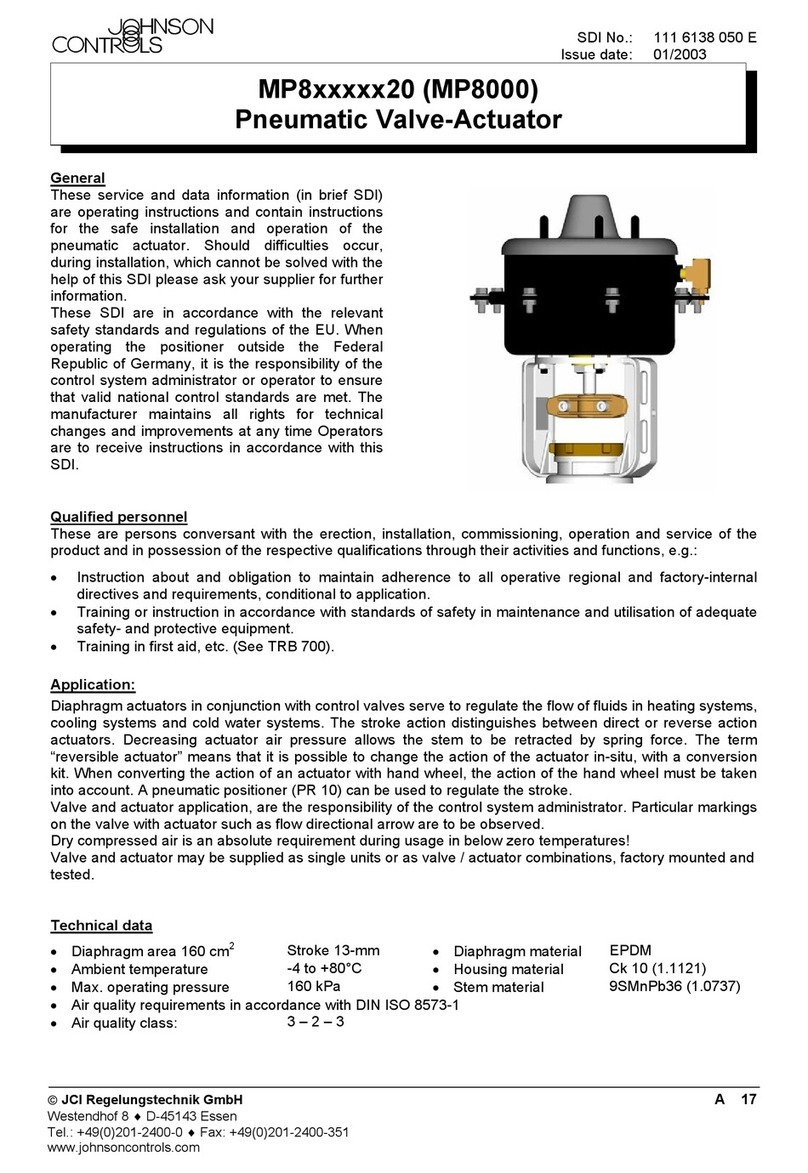

Johnson Controls MP8 20 Series User manual

Johnson Controls

Johnson Controls Tyco KT-1 User manual

Johnson Controls

Johnson Controls VA-747 Series User manual

Johnson Controls

Johnson Controls NAE35 User manual

Johnson Controls

Johnson Controls FX-PCA4911 User manual

Johnson Controls

Johnson Controls FAC2612-2 User manual

Johnson Controls

Johnson Controls HS3032 User manual

Johnson Controls

Johnson Controls NAE Instruction Manual

Johnson Controls

Johnson Controls LN Series User manual

Johnson Controls

Johnson Controls TEC3000 Series User manual

Johnson Controls

Johnson Controls NEO Series User manual

Johnson Controls

Johnson Controls M9108-A-1N Series User manual

Johnson Controls

Johnson Controls A25CN Series Guide

Johnson Controls

Johnson Controls FX-PCV1930 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions