Joto E-HP-JAR-DS-1620 User manual

Joto Manual Shuttle Press Manual

Model No.: E-HP-JAR-DS-1620

OPERATOR’S MANUAL

Bringing images to life

TM

TM

2

Safety Instructions

For Use By Qualied Personnel Only

When using your Heat Press,

basic precautions should always be followed,

including the following:

Read all instructions.

Use heat press only for its intended use.

Keep the heat press dry at all times. Do not get the heat press wet to reduce the risk of electric

shock. Do not store heat press in a wet or damp area.

Never pull cord to disconnect the power, grasp plug and pull to disconnect from power outlet.

Protect the power cord by keeping it away from hot surfaces. Do not allow objects to sit on top of

the cord. This could cause damage to the cord and could become a re hazard risk.

Do not operate heat press with a damaged cord or if the equipment has been damaged. Do not

disassemble or attempt to repair the heat press to prevent risks to injury. Call or take it to a

qualied service person for examination and repair. Incorrect assembly or repair could increase the

risk of re, electric shock, or injury to persons when the equipment is used.

Supervision is necessary for any heat press being used by or near children. Do not leave equipment

unattended while connected.

Metal parts on the press can become hot. Burns may occur when touching hot metal parts. Take

caution when using the heat press

To reduce the likelihood of circuit overload, It is recommended to use a dedicated circuit if possible.

Care should be taken to arrange the cord so that it cannot be pulled or tripped over.

To reduce the likelihood of circuit overload, do not operate other high voltage equipment on the

same circuit.

If an extension cord is necessary, then a 20 amperage rated cord should be used. Cords rated for

less amperage may overheat. Care should be taken to arrange the cord so that it cannot be pulled or

tripped over.

Note: This heat press should not be set to exceed 210C. Setting the press temperature to above

210C may cause a re hazard.

3

Congratulations on your purchase of a Joto Manual Shuttle Heat Press! In order to work

professionally with the machine and start production, please make sure you read this manual

carefully. Reproduction of this manual requires written consent from Joto. Errors and

amendments of technical details excepted, all rights reserved. Joto is not liable for any direct or

indirect damages caused by the use of this product.

Table of Contents

Safety........................................................2

Introduction .............................................3

Setting Up Your Heat Press ......................4

Operating Instructions .............................6

Heat Press Overview ................................7

Maintenance .............................................8

Joto Sublimation/Transfer Vinyl Guide .... 8

Circuit Diagram .........................................9

Expanded View .......................................10

Contact ...................................................12

4

Turning On Your Heat Press

Turn the Main Power Switch on. The

Main Power Switch is at the side

of the heat press.

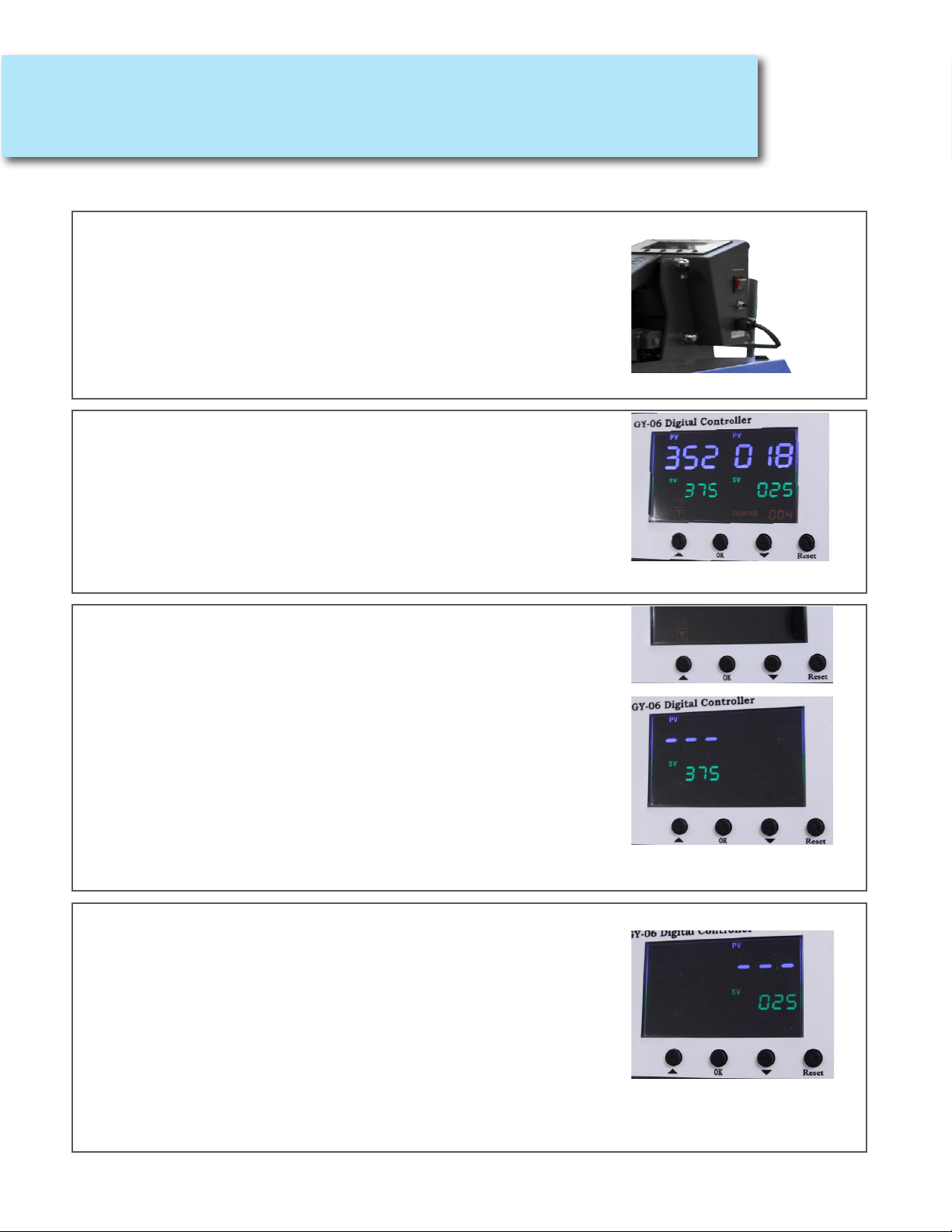

Current temperature, set temperature,

current time, set time will display.

How to Read The Display

1.) Left side PV value = Current Temperature

2.) Right side PV value = Current Time

3.) Left side SV value = Set Press Temperature

4.) Right side SV value = Set Press Time

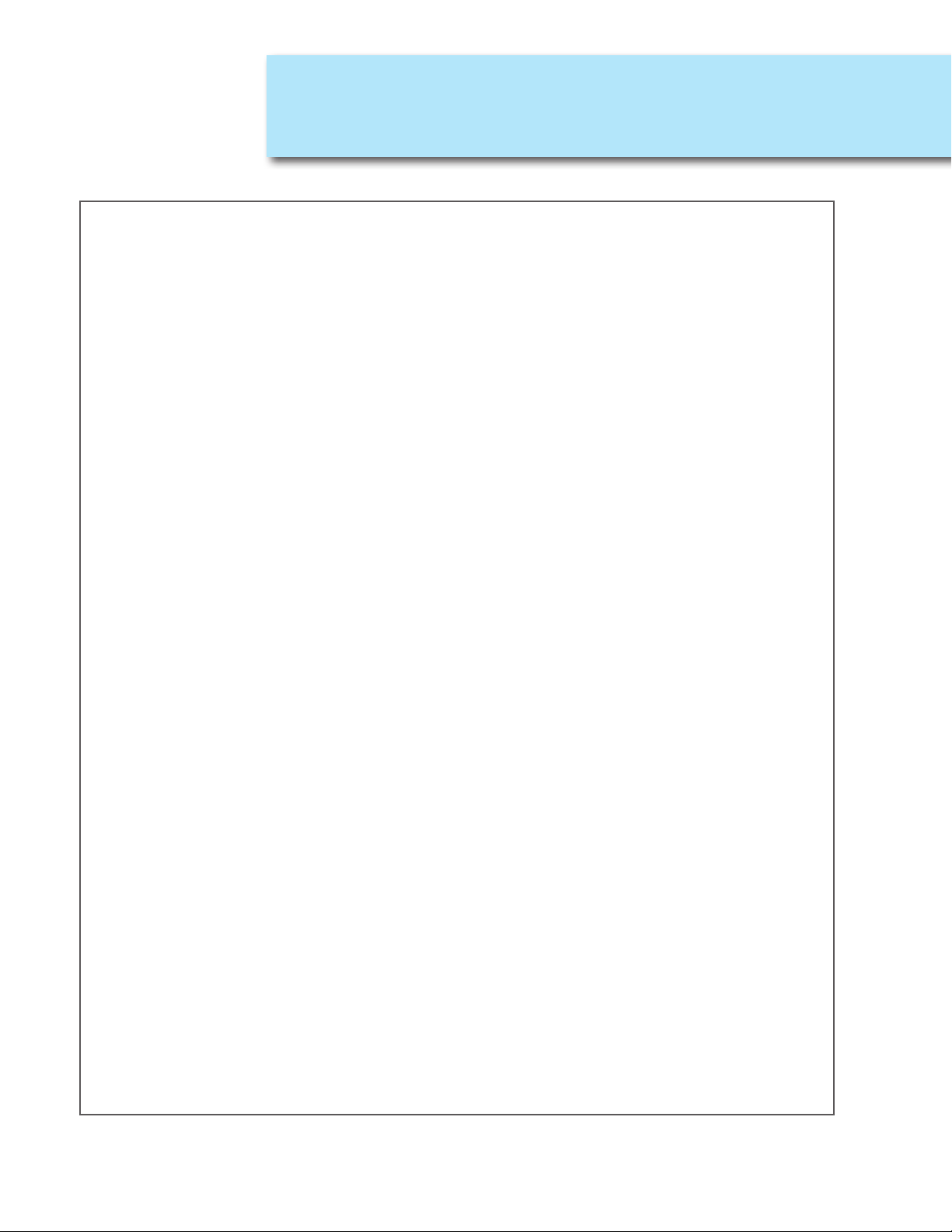

Setting Press Temperature

Press OK to start. Use the up and down

arrows to choose to display in °F or °C.

°F stands for Fahrenheit

°C stands for Celsius

Once selection is made, press ok to save

Greensettemperaturevaluewillash.

Use the up and down arrows to set

press temperature value. Press ok to save

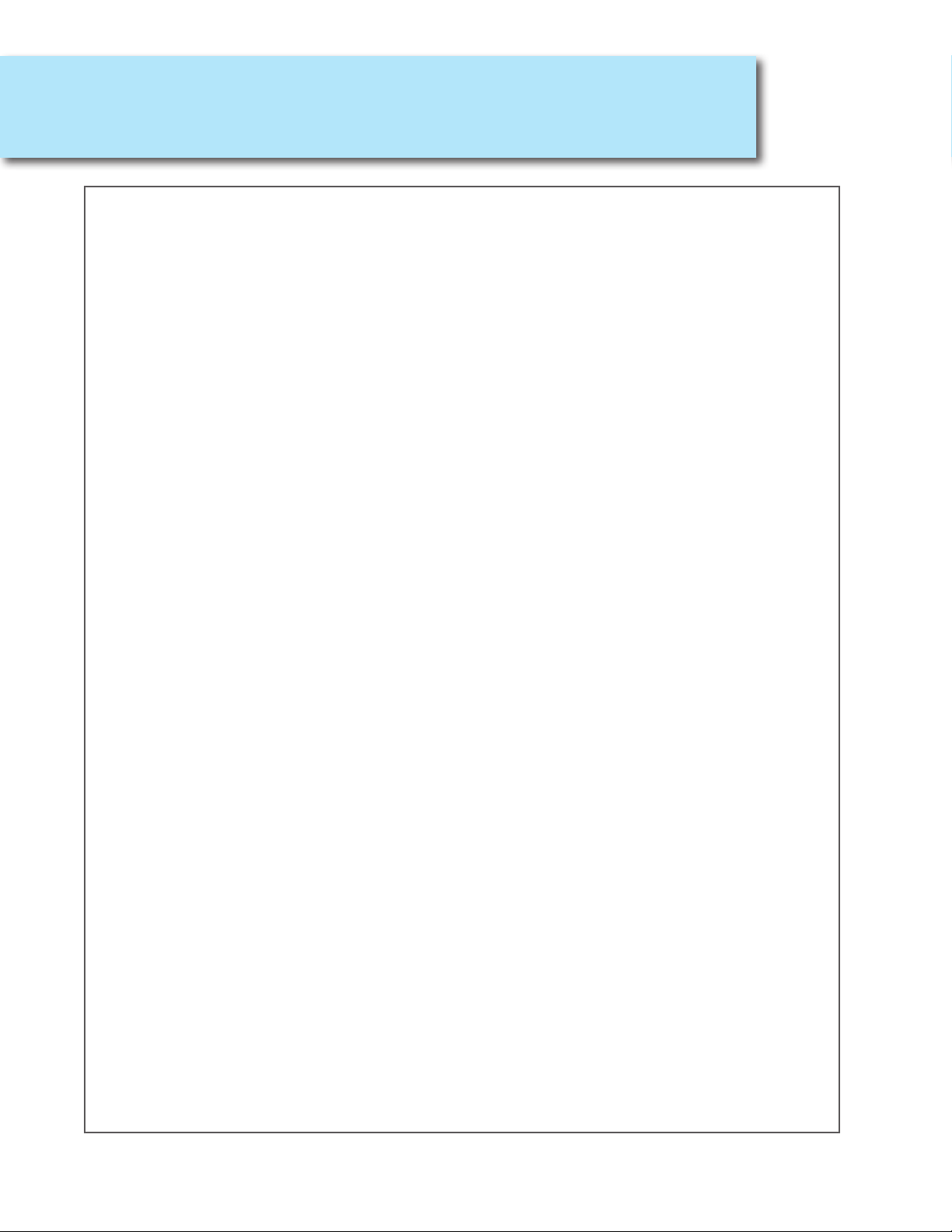

Setting Press Time

GreenSetTimeValuewillash

Use the up and down arrows to change

the value.

Press ok to save the value.

Wait until the current

temperature is the same as the set temperature

before using. The press will beep once set temperature

is reached. Close and open the press to stop the beeping

Setting Up Your Heat Press

Note:Settingthepresstemperaturetoabove210Cmaycausearehazard.

5

Operating Instructions

Pressing a T-shirt

1.) Turn on the Main Power Switch

2.) Set the appropriate Press Temperature, and Time as per your transfer vinyl

or sublimation instructions.

3.) Place your t-shirt on the heat press.

5.) Set the pressure by adjusting the air pressure adjust knob.

6.) Wait until current temperature is the same as the set temperature. Once the

press has reached set temperature, place transfer material on the shirt. For

Sublimation, place the paper with the image face down. For cuttable transfer

vinyl, place the matte side with the transparent carrier backing facing the heat

platen. If unsure, please refer to the instructions you received with your

transfer materials.

7.) Slide the heat platen towards the base plate you are pressing. Press the two

start switch buttons to close the press. Once press is closed the current time

value will start counting down. Once the timer reaches the last 2 seconds before

reaching0,itwillstarttobeeptowarnyou.Oncetimereacheszero,thepress

will open. Slide the heat platen over to press on the next plate.

Note: Once the press is closed, it cannot be opened manually until the timer

reacheszero.Inanemergency,youmaypresstheemergencyswitch

to force open the press. When pressing the emergency switch, the

press will open immediately without warning. Keep hands on the heat press

handle at all times during and after pressing the emergency switch. Not

securing the handle with your hands may cause injury.

8.) For most sublimation and transfer vinyl, the peel is hot. If unsure, refer to the

instructions that came with your transfer materials.

Operation of throttle valves:

On the right side of the press head there are two silver screws where the speed of the

press opening and closing can be adjusted. Tightening the top screw (turning clockwise)

will decrease the speed the press opens. Tightening the bottom screw (turning clock-

wise) will decrease the speed the press closes. Loosening the screws (turning counter

clockwise) will increase the speed. Adjust accordingly.

6

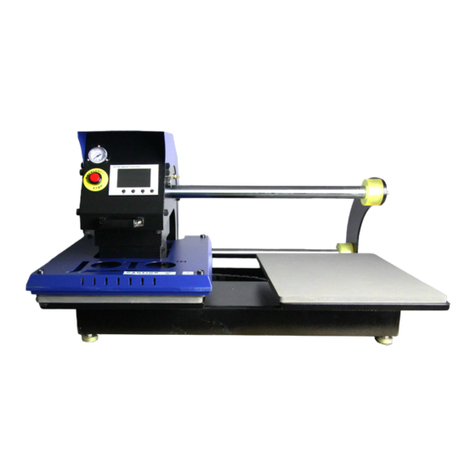

Heat Press Overview

Note: This heat press should not be set to exceed 210C. Setting the press temperature to

above210Cmaycausearehazard.

Technical Specs

Model No.: E-HP-JAR-DS-1620

Machine Type: Manual Shuttle Press

MachineSize: 34.5” x 29.5” x 14” (87.63cm x 47.93cm x 35.56cm)

HeatPressplatenSize: 16” X 20”

Maximium Thickness: 1.20” (30mm)

Controller GY-06 Digital Controller

Voltage: 120V 14amp

Power: 1500W

Time Range:

Maximum Temp:

0-999 Seconds

410°F (210°C)

PackingSize: 39.76” x 34.64” x 22.8346” (101cm x 88cm x 58cm)

Gross Weight: 209lbs (95kg)

7

Maintenance

Heat Press Guide

General Maintenance

Please switch off the machine and unplug the power cord when the machine is not

in use.

To protect the heat platen, do not allow any hard surface objects to be in direct con-

tactwiththeplaten.Thisincludeszippers,buttons,metalsublimationitems.When

pressing these items, place a protective sheet between the platen and the objects.

The heat-releasing fan will automatically starts when the temperature of heat platen

reaches 80 degree C (176 degree F). It helps to reduce the temperature of electrical

parts and prolong the service life of them.

Heat platen may pivot slightly back and forth. This is due to movement allowance

within the clamp assembly, and is normal.

Please add the lubrication oil regularly on the joints to prolong the life of your heat

press. The frequency will depend on how often you use your machine.

When changing parts, turn off the power, To ensure the accuracy of GY-06 controller,

rest time and temperature.

Note: This heat press should not be set to exceed 210C. Setting the press

temperature to above 210C may cause a re hazard.

MultiCut Ultra Matte

Temperature: 320F

Time: 20 seconds

Peel: Hot

MultiCut Flock Premium

Temperature: 320F

Time: 20 seconds

Peel: Hot

MultiCut Nylon

Temperature: 345F

1st Press Time: 3 seconds

2nd Press Time: 10 seconds

MultiCut Premium

Temperature: 320F

Time: 10 seconds

Peel: Hot

MultiCut Lustre

Temperature: 310-330F

Time: 15-20 seconds

Peel: Hot to Cold

MultiCut Style

Temperature: 310-330F

Time: 15-20 seconds

Peel: Hot to Cold

8

Sublimatable Ceramic Tiles

Temperature: 400F

Time: 360-420 seconds

Peel: Hot

Method: Substrate face down

Image face up

Porcelain Ornaments

Temperature: 400F

Time: 180-240 seconds

Peel: Hot

Method: Substrate face down

Image face up

MousePads/CanCoolers

Temperature: 400F

Time: 35-45 seconds

Peel: Hot

Method: Substrate face up

Image face down

Coasters/Fabric Puzzles

Temperature: 400F

Time: 35-45 seconds

Peel: Hot

Method: Substrate face up

Image face down

Phone cover inserts

Temperature: 360F

Time: 120 seconds

Peel: Hot

Method: Substrate face down

Image face up

Unisub Metals

Temperature: 400F

Time: 60 seconds

Peel: Hot

Method: Substrate face up

Image face down

Unisub Plastics

Temperature: 400F

Time: 75-80 seconds

Peel: Hot

Method: Substrate face up

Image face down

Unisub Wood

Temperature: 400F

Time: 75-80 seconds

Peel: Hot

Method: Substrate face up

Image face down

Unisub Plaques

Temperature: 400F

Time: 75-80 seconds

Peel: Hot

Method: Substrate face up

Image face down

ilumiPix Photo Panels

Temperature: 360-375F

Time: 120-140 seconds

Peel: Hot

Method: Substrate face down

Image face up

Sublimation Items

Heat Pressing Guide (continued)

9

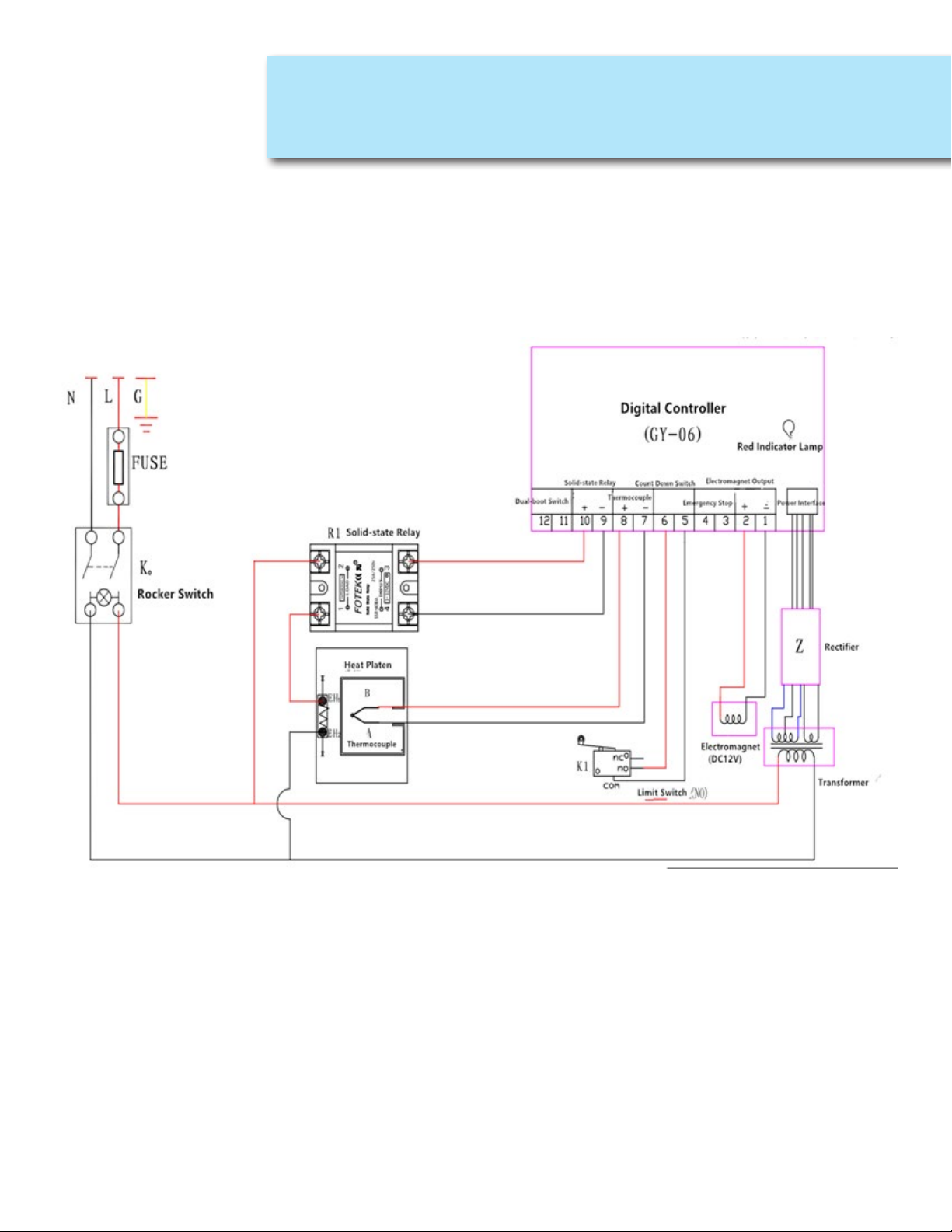

Circuit Diagram

10

Expanded Diagram

Other manuals for E-HP-JAR-DS-1620

1

Table of contents

Other Joto Power Tools manuals

Joto

Joto E-HP-JMP-51N User manual

Joto

Joto E-HP-JCH-51 User manual

Joto

Joto E-HP-JLF-3243 User manual

Joto

Joto E-HP-JAR-1515 User manual

Joto

Joto E-HP-JMP-1S2E User manual

Joto

Joto E-HP-JMP-1S7E User manual

Joto

Joto E-HP-JMP-2S5E User manual

Joto

Joto E-HP-JAR-DS-1620 User manual

Joto

Joto XSTM-40 User manual

Joto

Joto E-HP-JSP-1620 User manual