7

www.jotoimagingsupplies.com 1-800-565-5686 Blaine, WA | Las Vegas, NV | Antioch TN | Coquitlam, BC | Brampton, ON

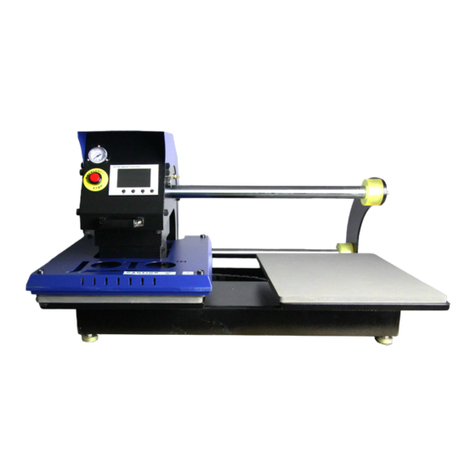

Operating Instructions

Pressing a images to your substrate

1.) Ensure that the air supply is connected to the press.

2.) Turn on the Main Power Switch.

3.) Adjust the air pressure to 0.6-0.8Mpa. Heat platen will open automatically.

4.) Draw out the under plate and place the substrate on top of the under plate.

5.) Set the appropriate Press Temperature, and Time as per your transfer paper,

transfer vinyl or sublimation instructions.

6.) Wait until current temperature is the same as the set temperature. Once the

press has reached set temperature, place transfer material on the shirt. For

Sublimation, place the paper with the image face down. For cuttable transfer

vinyl, place the matte side with the transparent carrier backing facing the heat

platen. For some sublimation items, the imaged transfer paper is on

the bottom with image face up while the substrate is placed on top with printable

side face down. If unsure, please refer to the instructions you received with your

transfer materials.

7.) Push the green start-up switch. The platen will close automatically.

The current time value will start counting down. Once the

timer reaches the last 2 seconds before reaching 0, it will start to beep to warn

you. It is recommended to stand clear of the press and let the auto-open

feature work without obstruction. Once time reaches zero, the press will open.

Note: Once the press is closed, it cannot be opened manually until the timer

reaches zero. In an emergency, you may press the red emergency stop button

to force open the press. When pressing the red emergency stop button, the

press will open immediately without warning. Keep hands on the heat press

handle at all times during and after pressing the emergency stop button. Not

securing the handle with your hands may cause injury.

8.) For most sublimation and transfer vinyl, the peel is hot. If unsure, refer to the

instructions that came with your transfer materials.

CAUTION: Suitable air pressure is 0.4-0.5Mpa or 75-80Psi. Do not exceed this range as

too much air pressure may damage the machine, and not enough air pressure

will not allow the heat platen to work properly.