– 3 –

❷

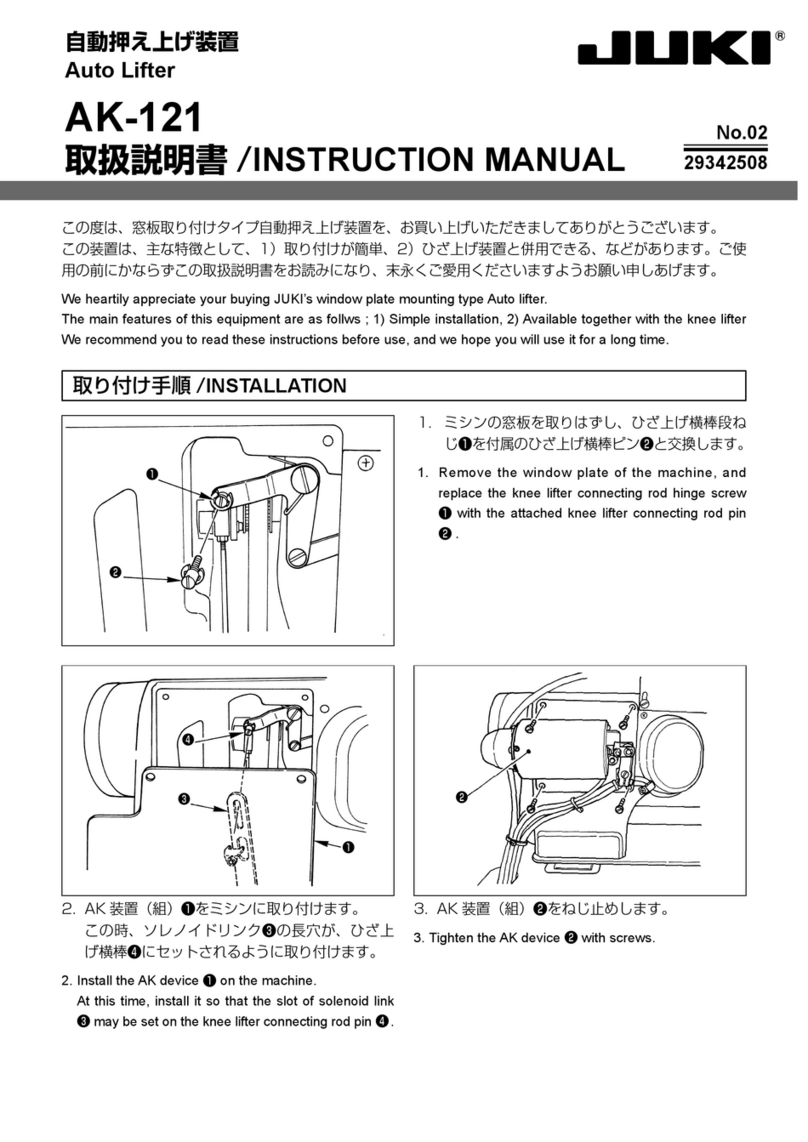

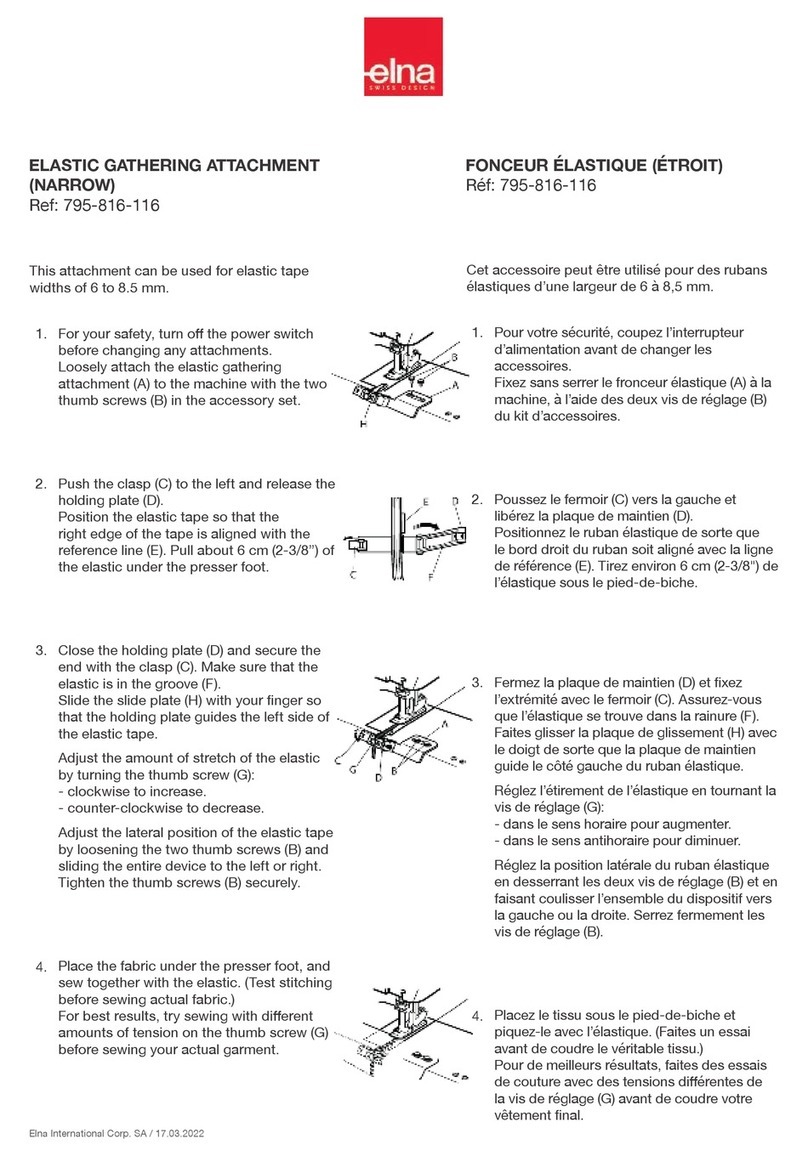

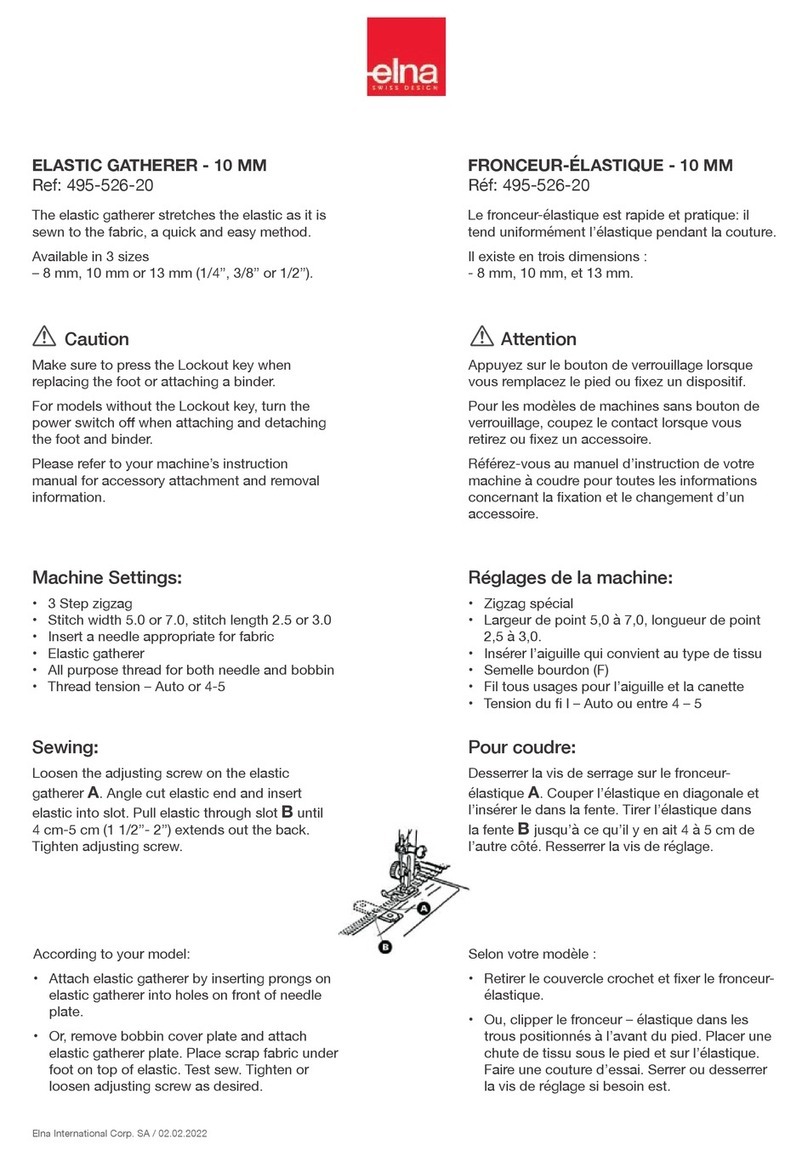

5) Align the scale mark "7" of the stitch dial ❷with

the marker dot on the machine arm. Place a spac-

er ❼with plate thickness of 1 mm between the

reverse feed lever ❺and the reverse feed lever

stopper ❻.

6) Loosen the setscrews of the feed lever arm

(asm.).

7) While pushing up the reverse feed lever ❺to

prevent the 1-millimeter spacer ❼from slipping

out, tighten the setscrew of the feed lever at

the position where the feed lever arm pin ❽lightly

comes in contact with the feed regulating rod ❾.

8) Align the scale mark "7" of the stitch dial ❷with

the marker dot on the machine arm. At this time,

check to make sure that thread is a slight back-

lash (play) in the reverse feed lever ❺in its mov-

ing direction.

(Caution) If there is no aforementioned backlash,

abnormal noise or breakage of the re-

lated parts may occur while the sewing

machine is in operation.

9) Turn the handwheel by hand in the direction of the arrow to check the actual stitch length.

Inthecasetheactualstitchlengthdiersfromthestitchlengthsetwiththestitchdial❷, loosen the set-

screw of the feed regulating base and adjust the feed regulating pin with an open-end wrench.

❺

❻

❽

❾

❼