- 4 -

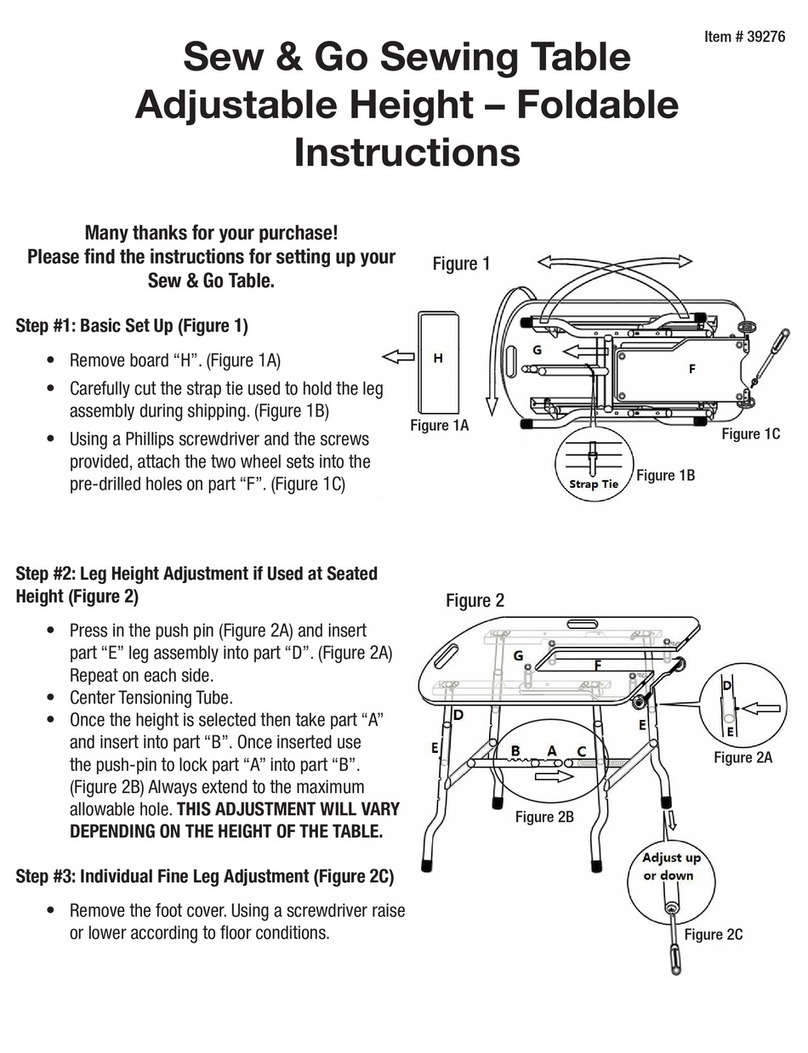

5. Assembly procedures

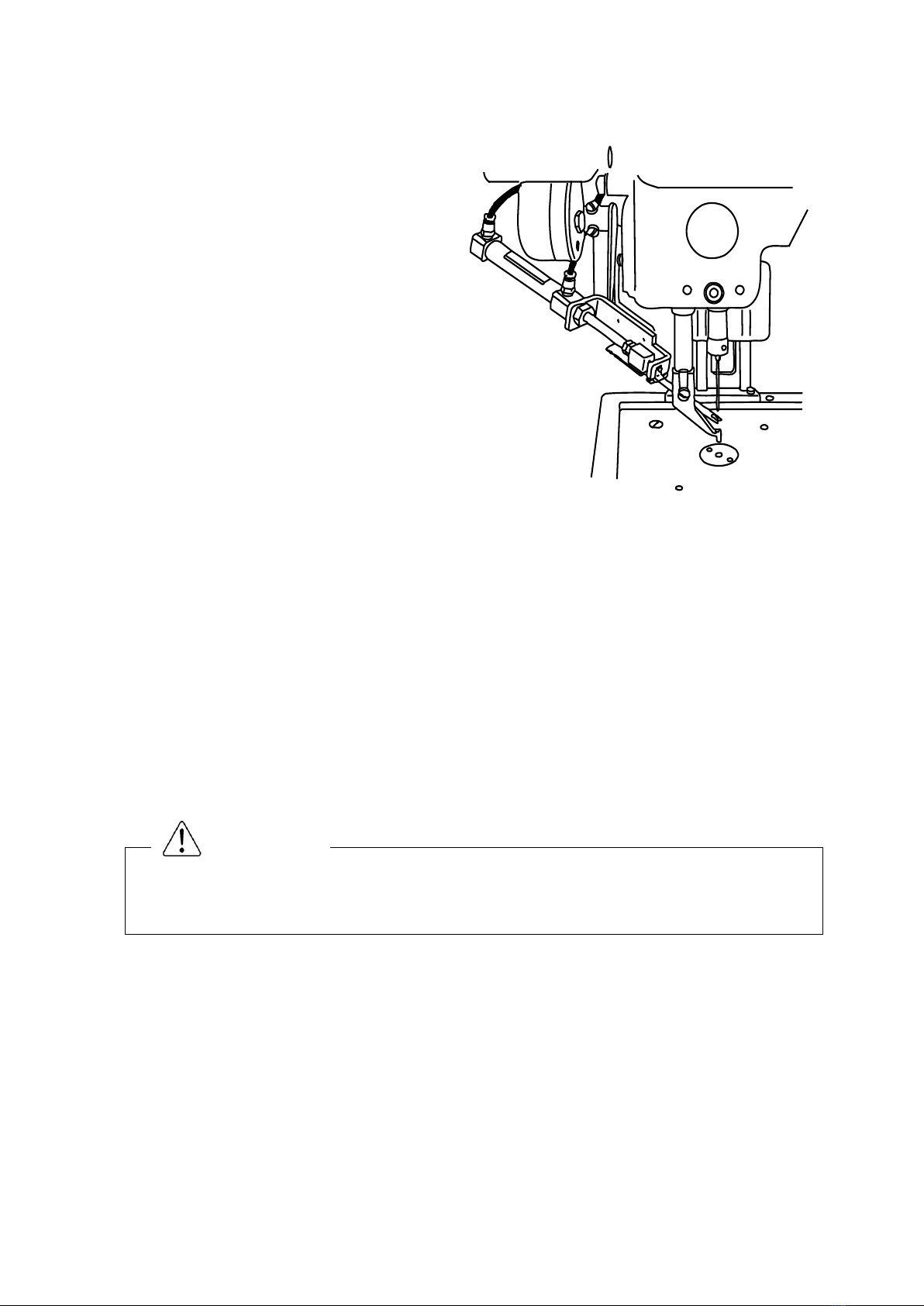

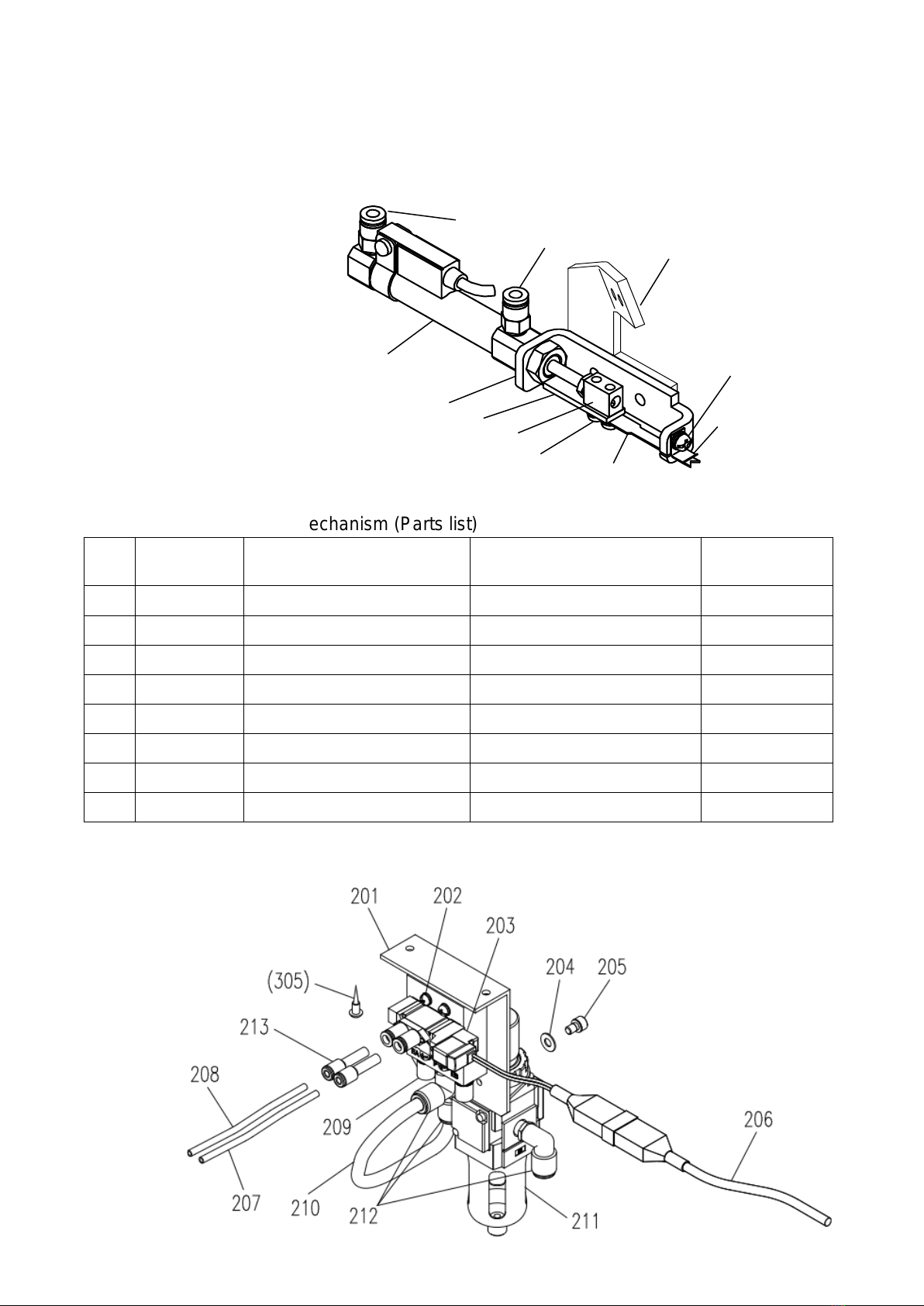

5.1 Installing the upper thread holding mechanism

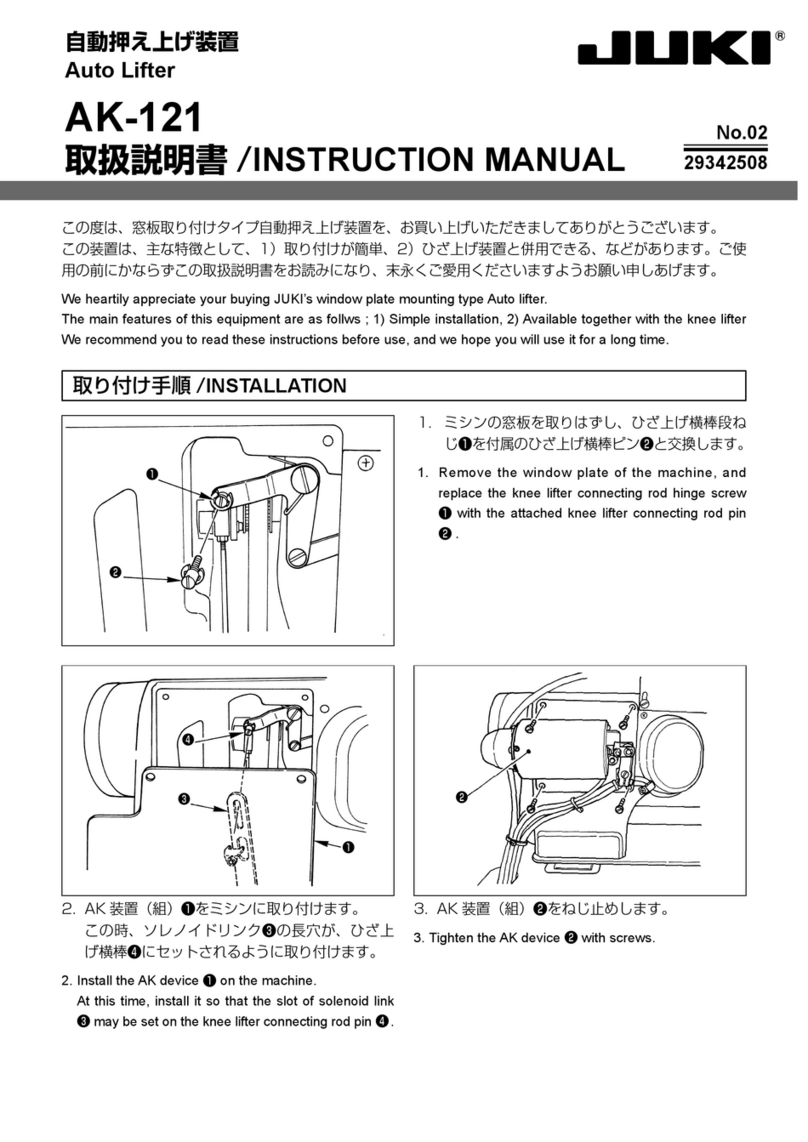

(1) Make a bracket for mounting the upper thread holding mechanism.

(Shows an example in Figure 2.)

★Please consult sewing machine shop for the fabrication of bracket.

The mounting of the upper thread holding mechanism, you can use the mounting holes of the wiper

mechanism, to or attached to the face cover. Attach a position that does not interfere with the holding jig

to position the sewing material, consider including the sewing pattern and workability.

(2) Remove the wiper mechanism from the machine arm. Is not only part of the wiper drive, please remove

the connection wires from the sewing machine.

★Can not be shared with the wiper mechanism and Upper Thread-Holding Device.

(3) Attach the upper thread holding mechanism to the machine arm. Please adjust the position of the upper

thread holding mechanism so that the thread distributor Fig.No.106 scoop a thread between the presser

foot and the needle, as shown in Figure 1.

5.2 Installing the pneumatic pressure control related parts and piping

Please connect the pipes so that the state of the air cylinder rod is returned when the power is turned off. If

the rod is advanced, please replace the pipe to the joint A and B of the solenoid valve after the removal of

the air pressure to stop the air.

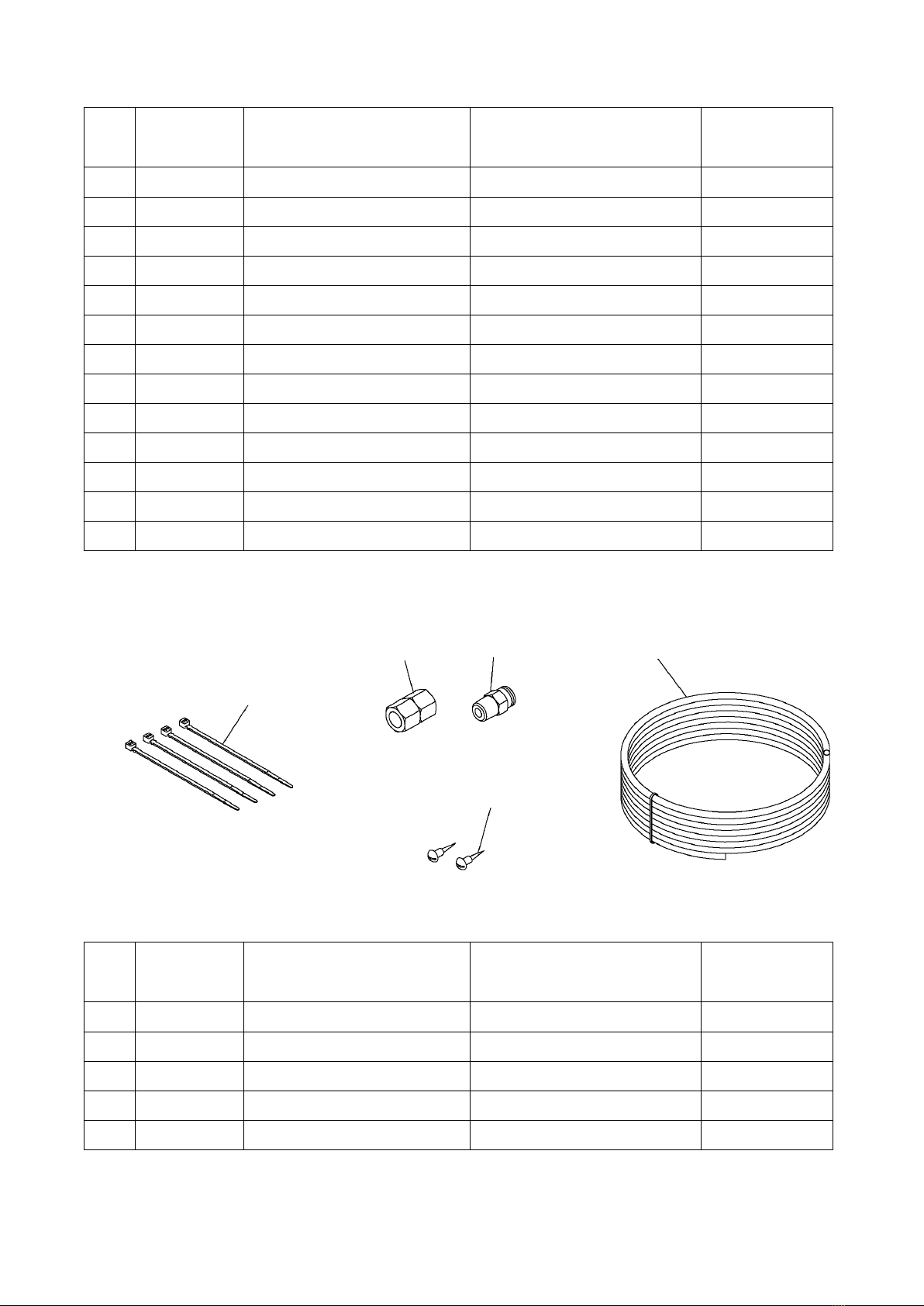

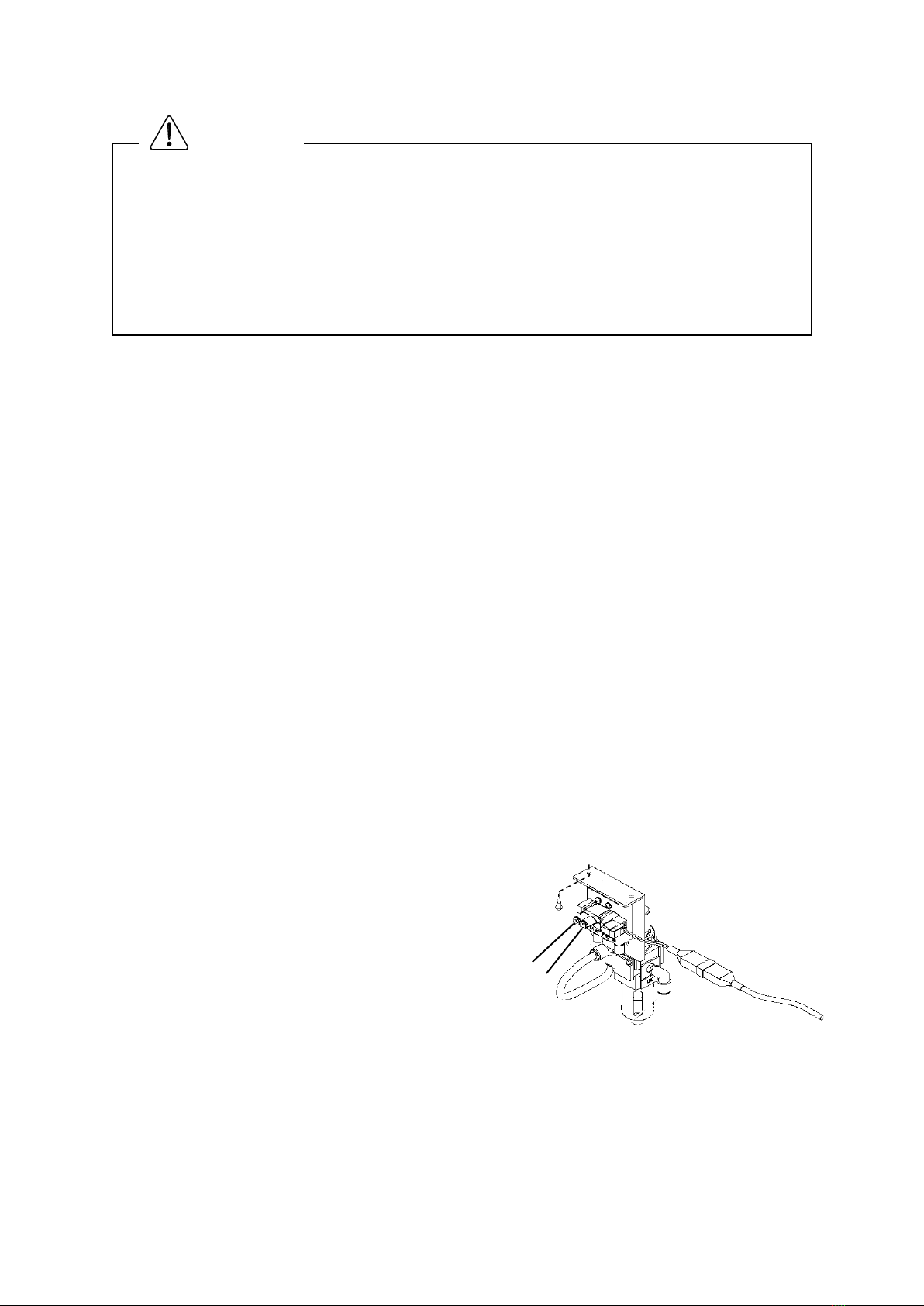

(1) Please fix with two wood screws provided

the pneumatic pressure control unit of sewing

machine table underside as shown in Figure

3.

(2) Insert to match the symbols A and B of the

air tubes "Fig.No.207 and 208" into the ports

"Fig.No.107A and 107B" of the upper thread

holding mechanism.

(3) Pass the air tubes through the notched

section on the side of the sewing machine

unit's motor cover, and lead the tubes to the

bottom of the table from the square hole on

the table.

(4) Insert to match the symbols A and B of the

air tubes into the ports "A and B" of the

solenoid valve.

(5) Bind the air tubes appropriately with the

enclosed Fig.No.301 Cable ties.

★To work in the presence of residual pressure in the pneumatic circuit It is dangerous. Please

work after you remove the residual pressure always. The method of removing the residual

pressure, and pull up the handle of the pressure regulating filter regulator, can be done by turning

counter-clockwise until the pressure gauge shows 0.

★When installing removal of parts, please go to turn off the power before. In addition, qualified

personnel of electrical work, please be performed by wiring work.