CONTENTS

Introduction............................................................................................................................. 1

I. Operation of the terminal (for operators)......................................................................... 1

1. Terminal display........................................................................................................... 1

1-1. Display of power-ON of the sewing machine....................................................... 1

1-2. How to view the terminal display.......................................................................... 2

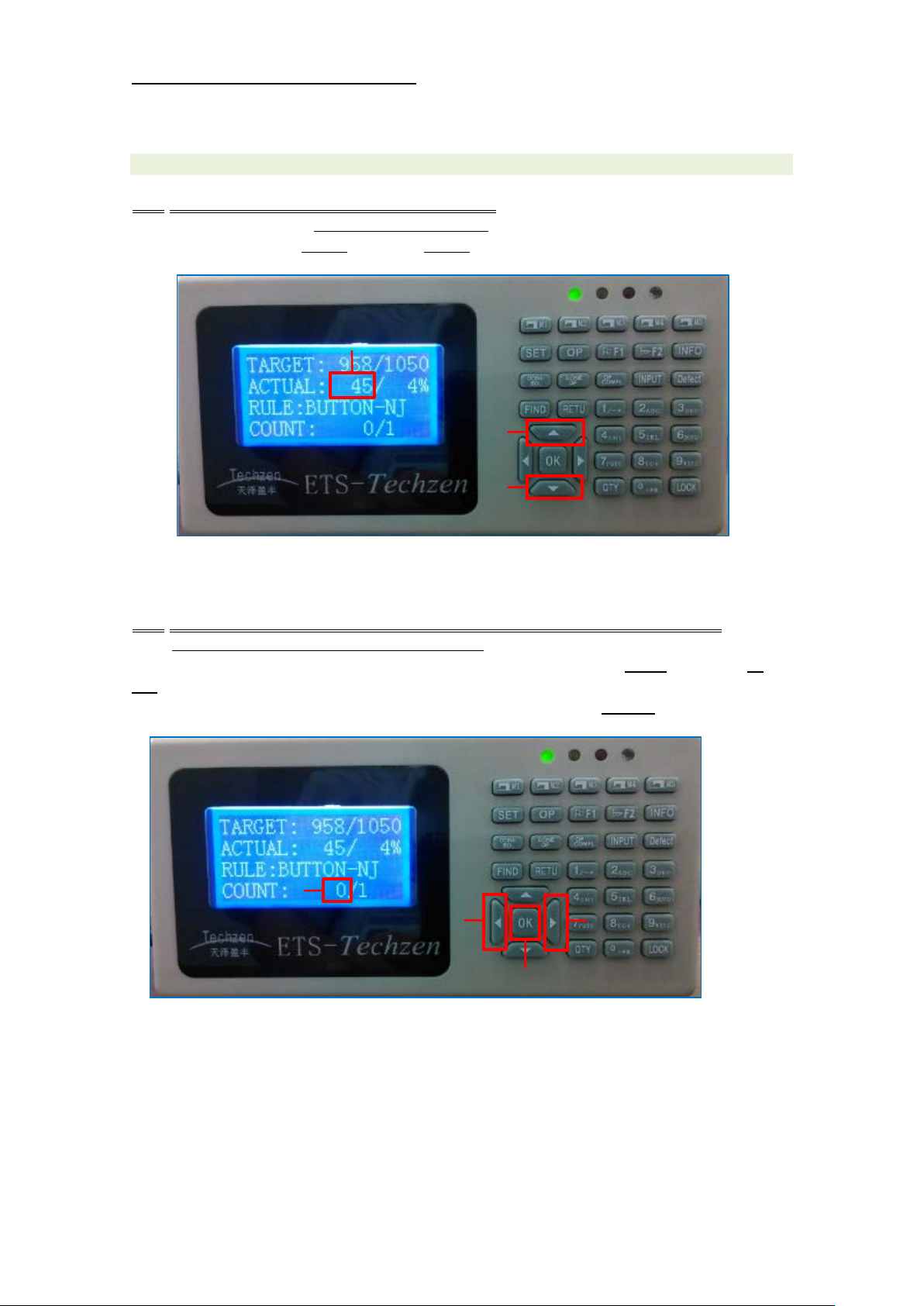

2. Correction of the quantity of output............................................................................. 3

2-1. How to correct the quantity of output ................................................................... 3

2-2. How to correct the current number of times of thread trimming .......................... 3

3. Maintenance call ......................................................................................................... 4

3-1. Issuing a maintenance call................................................................................... 4

4. Confirmation and change of machine settings ........................................................... 6

4-1. Confirming the machine settings.......................................................................... 6

4-2. Changing the count condition .............................................................................. 7

4-3. Changing the final process................................................................................... 8

4-4. Changing the machine number............................................................................ 9

II. How to use the report system (for line managers) ....................................................... 10

1. Dashboard................................................................................................................. 10

1-1. Selecting a line................................................................................................... 10

1-2. Real-time display items .......................................................................................11

2. Progress management monitor................................................................................. 12

2-1. Selecting a line................................................................................................... 12

2-2. Real-time display items ...................................................................................... 13

3. Operation rate chart of the sewing machine............................................................. 15

3-1. Operation rate chart on a line-by-line basis ....................................................... 15

3-2. Operation rate chart on a machine-by-machine basis....................................... 18

3-3. Time-series operation rate chart of the sewing machine................................... 20

4. Output-quantity chart................................................................................................. 22

4-1. Output-quantity chart on a section-by-section basis.......................................... 22

4-2. Time-series output-quantity chart....................................................................... 25

5. Net processing time chart ......................................................................................... 28

6. Output of CSV files.................................................................................................... 30

6-1. Operation on the screen..................................................................................... 30

6-2. Event list items ................................................................................................... 31

III. Restarting the server and management PC (for managers)....................................... 32

1. System configuration................................................................................................. 32