– 1 –

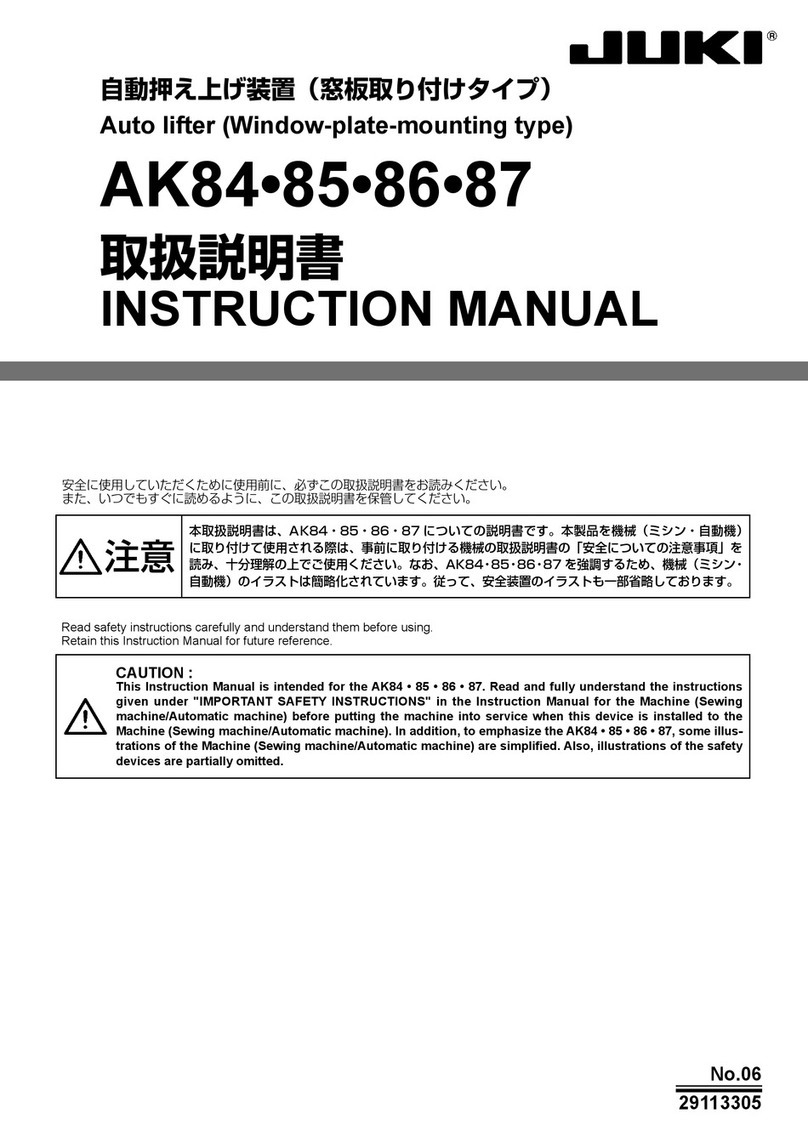

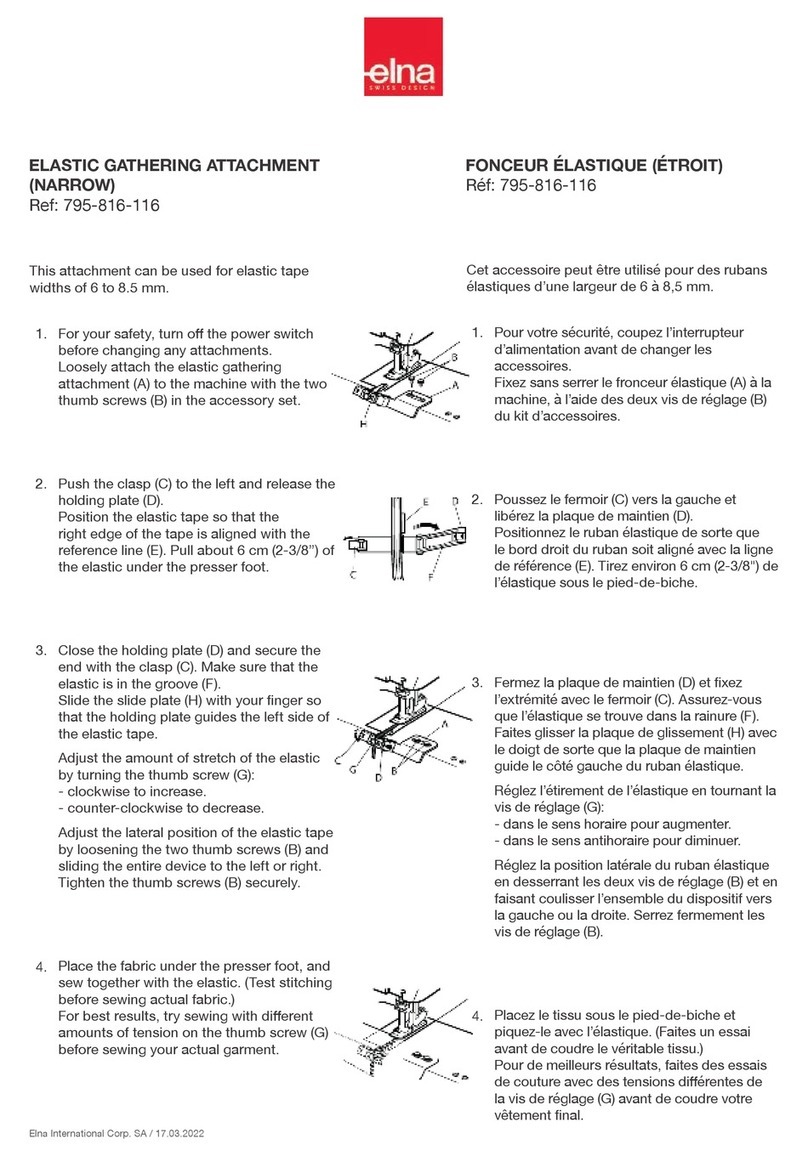

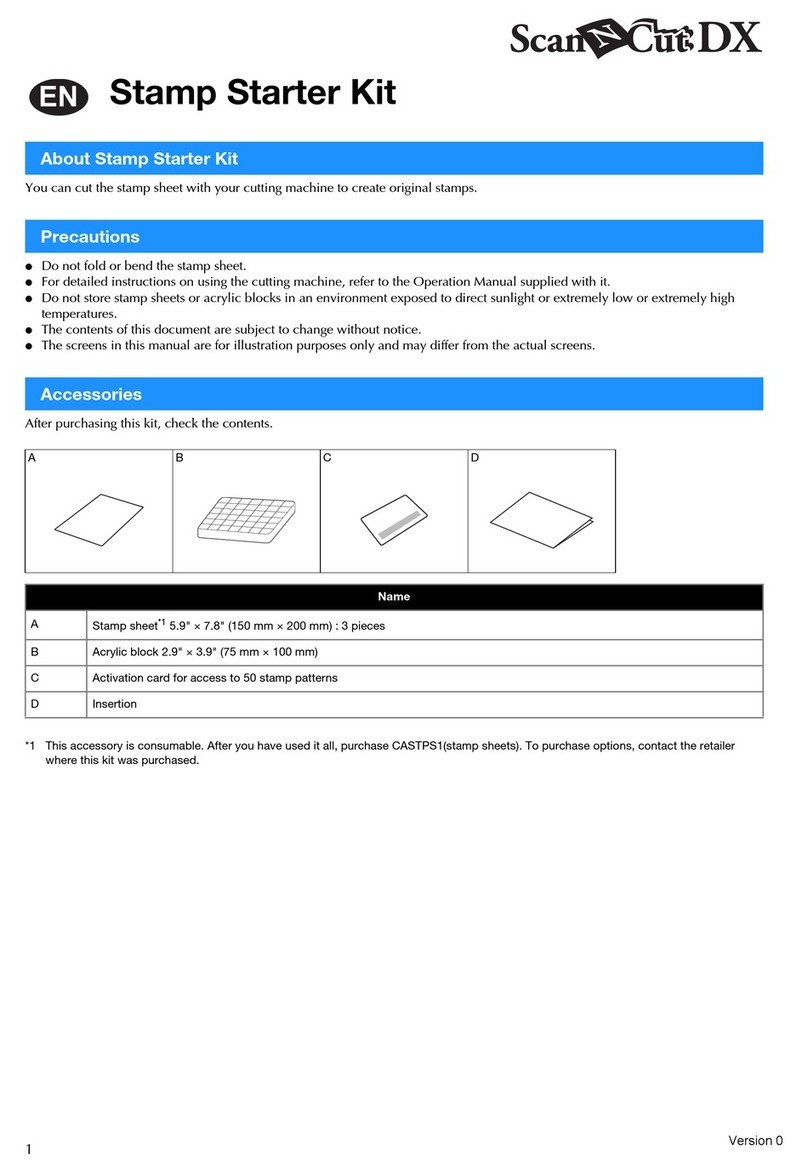

1. List of parts

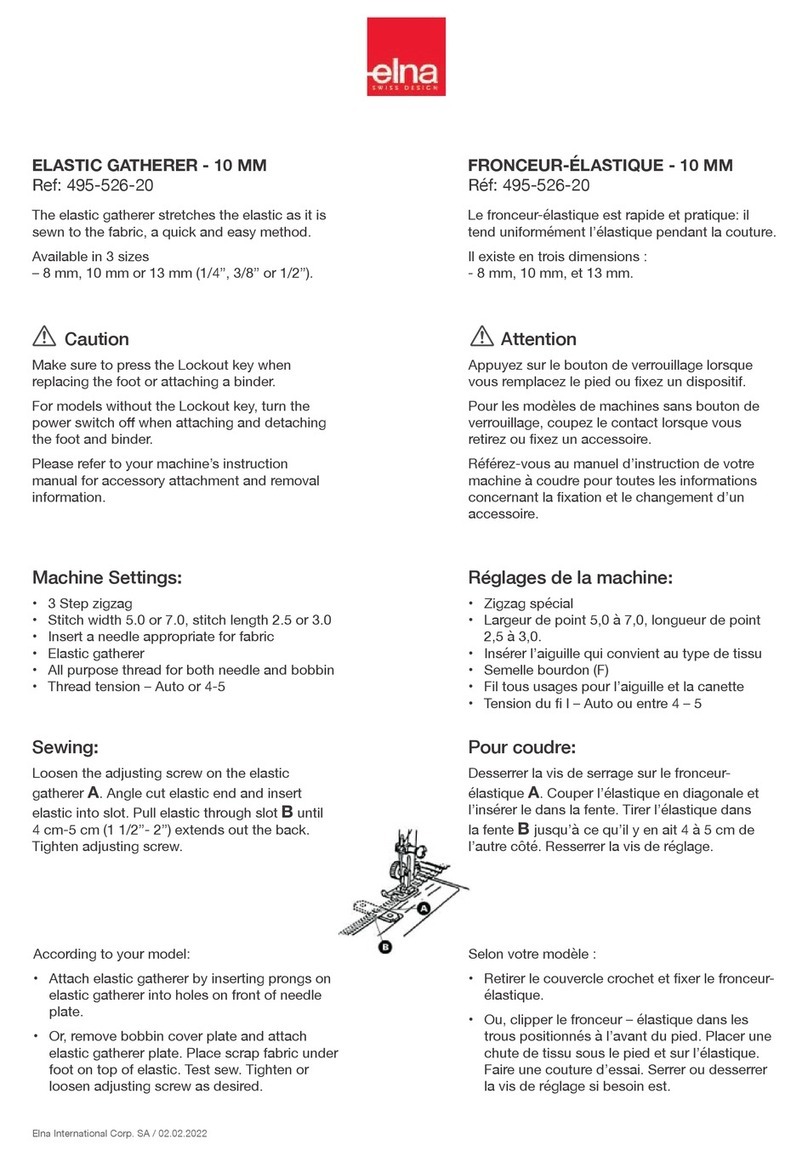

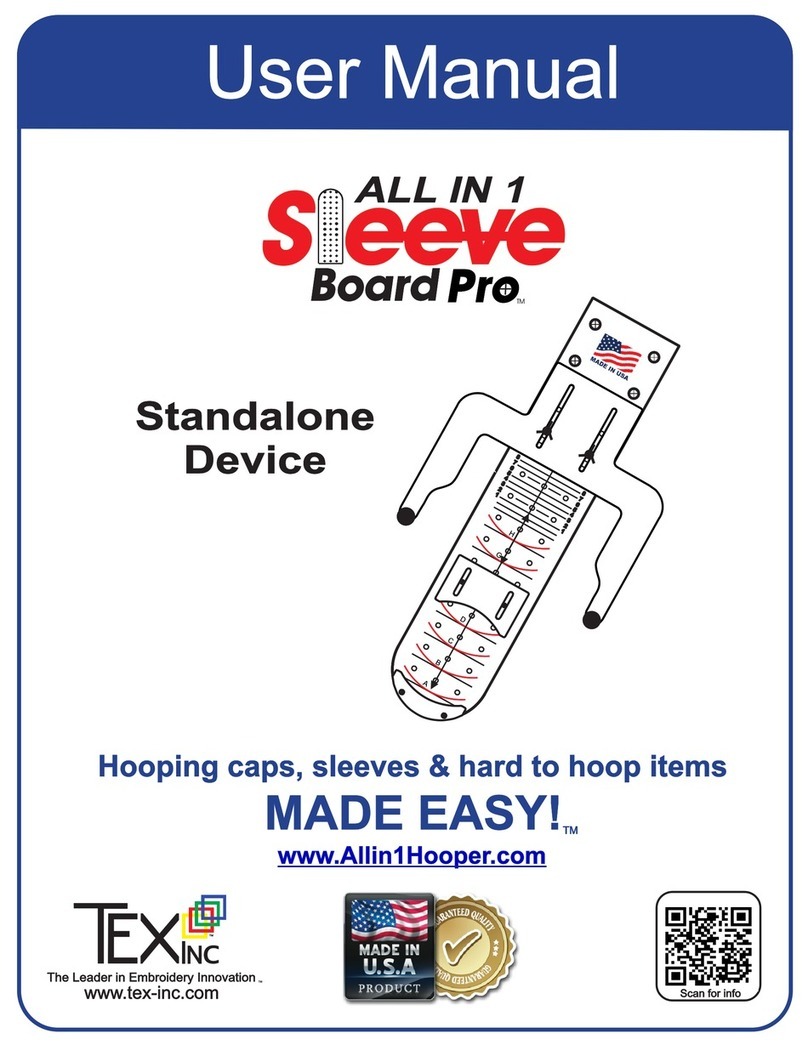

Active tension (asm.)

No. Part number Part name Qty

①40244934 Tension release auxiliary shaft (asm.) 1

①-1 40236683 Tension release auxiliary shaft (1)

①-2 40236685 Tension release auxiliary pin (1)

①-3 26201004 Guide pin (1)

①-4 RE0320000K0 E retaining ring (1)

②40244974 AT solenoid asm. 1

②-1 40236465 Solenoid (1)

②-2 RE0500000K0 E retaining ring (1)

②-3 NM6040000SN Hexagonal nut M4 1 type (1)

②-4 40236686 Solenoid screw (1)

②-5 40236680 Solenoid mounting plate (1)

②-6 40236681 Left AT shaft bushing (1)

②-7 SM1850600SP Countersunk head screw (2)

②-8 SM6040802TP Bolt screw (2)

①40244934 Tension release auxiliary shaft

①-2

①-1

①-4 ①-3

②40244974 AT solenoid

②-4

②-3

②-2

②-1 ②-5

②-6

②-7

②-8

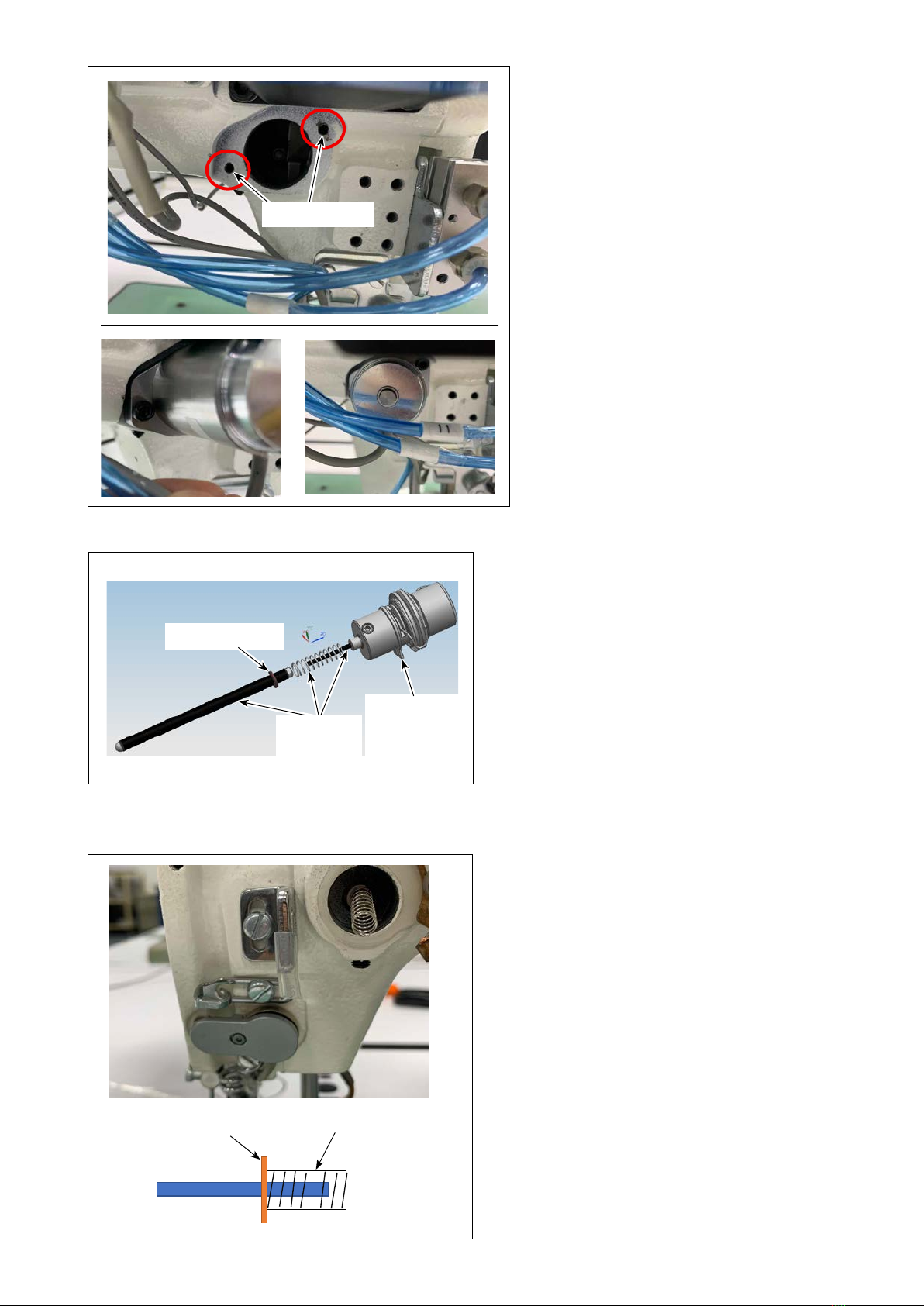

WARNING :

In order to prevent accidents caused by a sudden start of the sewing machine, the following proce-

dure has to be carried out after turning OFF the power supply and air supply to the sewing machine.