iii

CONTENTS

蠢. EXPLANATION OF LK-1900A, COMPUTER-CONTROLLED

HIGH-SPEED BARTACKING MACHINE .................................................................... 1

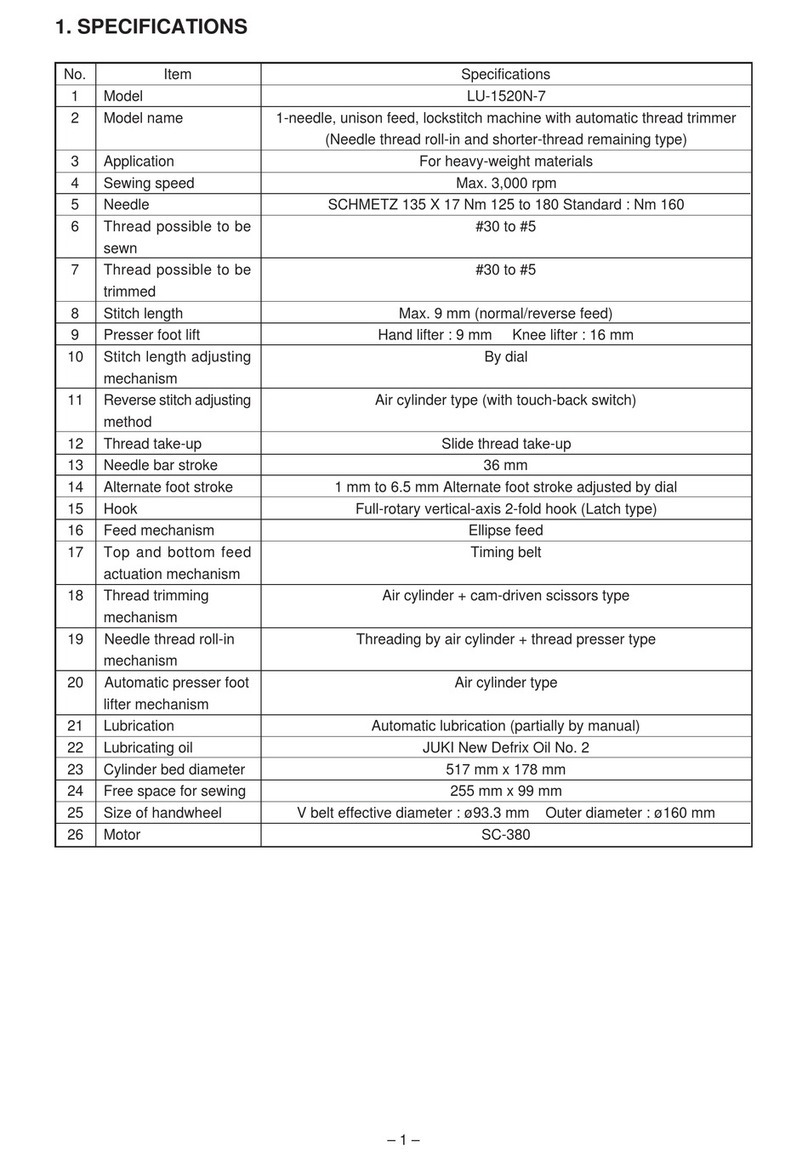

[1] SPECIFICATIONS .................................................................................................................................. 1

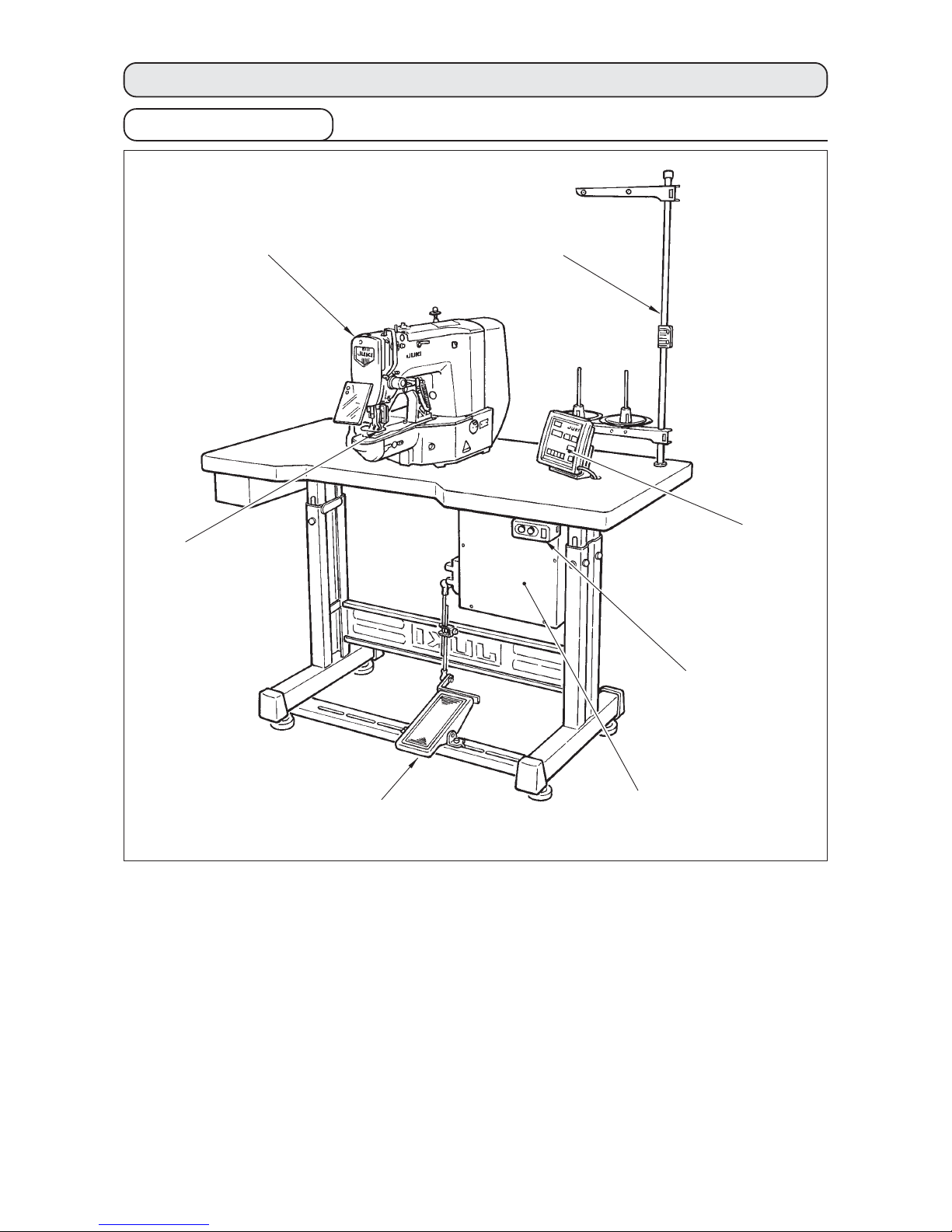

[2] CONFIGURATION .................................................................................................................................. 2

1. Names of main unit .......................................................................................................................................... 2

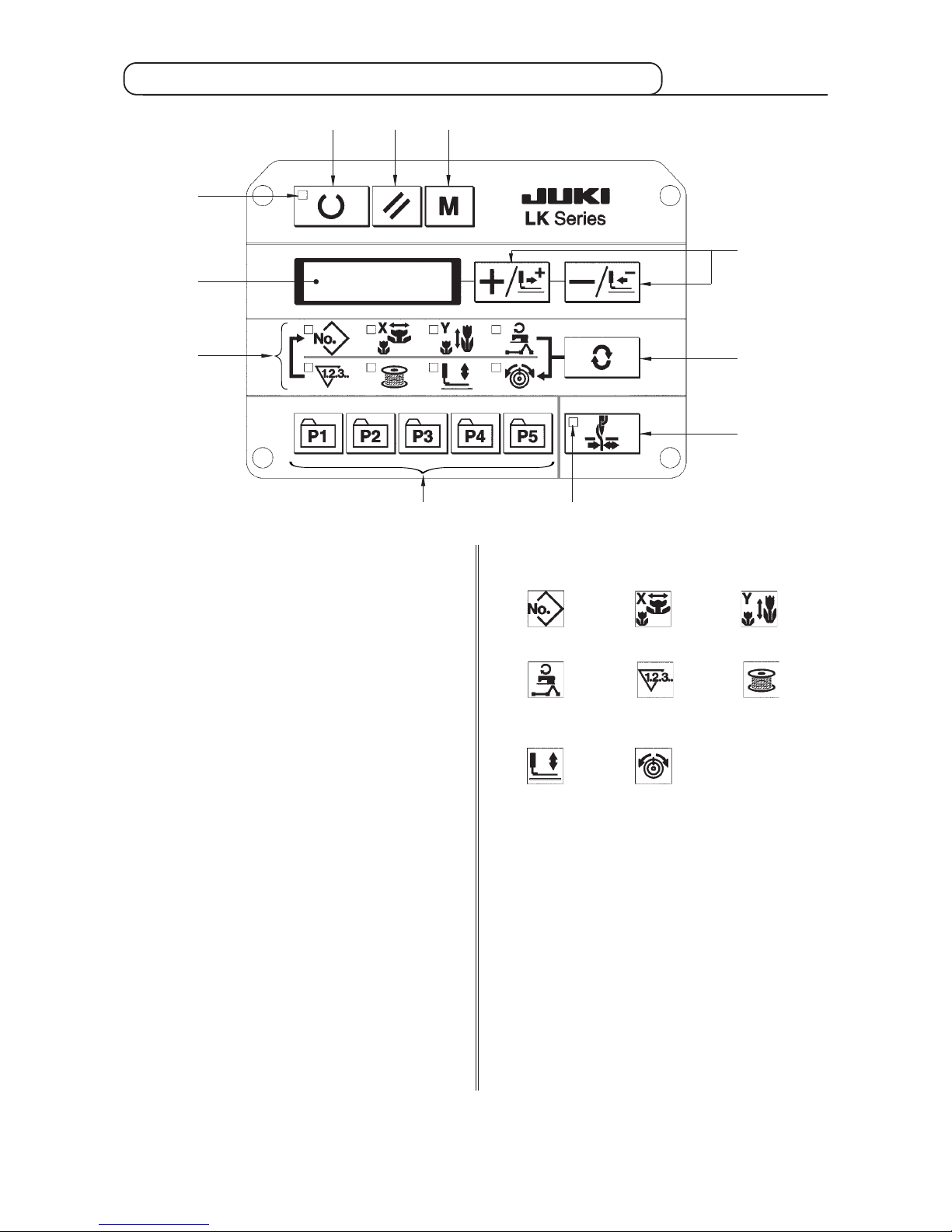

2. Names and explanation of switches on the operation panel ....................................................................... 3

[3] INSTALLATION ...................................................................................................................................... 4

1. Installing the electrical box ............................................................................................................................. 4

2. Attaching the connecting rod ......................................................................................................................... 4

3. Installing the head support rod ...................................................................................................................... 4

4. Installing and connecting the power switch.................................................................................................. 5

5. Installation of the sewing machine head ....................................................................................................... 6

6. Installing the drain receiver and the head support rubber .......................................................................... 6

7. Safety switch .................................................................................................................................................... 7

8. Tilting the sewing machine head .................................................................................................................... 7

9. Installing the operation panel ......................................................................................................................... 8

10. Connecting the cord ........................................................................................................................................ 9

11. Installing the motor cover ............................................................................................................................. 10

12. Managing the cord ......................................................................................................................................... 11

13. Installing the eye protection cover ............................................................................................................... 11

14. Installing the thread stand ............................................................................................................................ 12

[4] OPERATION OF THE SEWING MACHINE .......................................................................................... 13

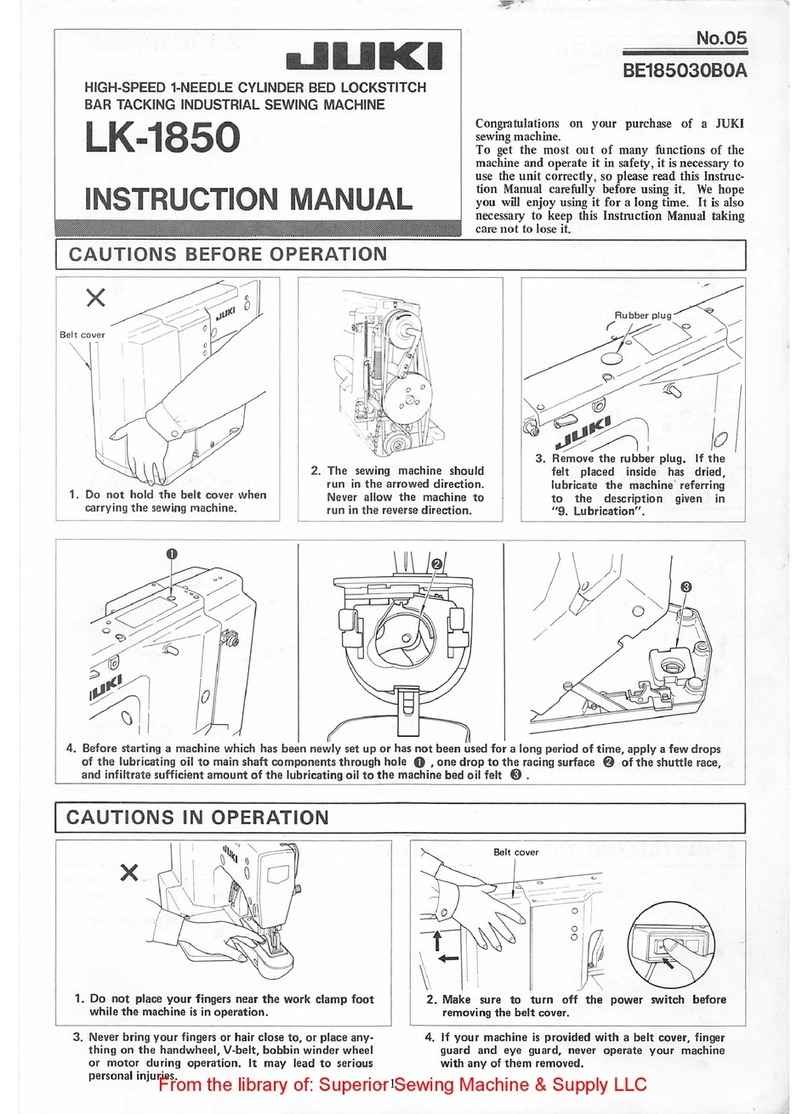

1. Lubrication ..................................................................................................................................................... 13

2. Attaching the needle ...................................................................................................................................... 13

3. Threading the machine head ........................................................................................................................ 14

4. Installing and removing the bobbin case .................................................................................................... 14

5. Installing the bobbin ...................................................................................................................................... 15

6. Adjusting the thread tension ........................................................................................................................ 15

7. Adjusting the thread take-up spring ............................................................................................................ 16

8. Example of the thread tension ...................................................................................................................... 17

[5] OPERATION OF THE SEWING MACHINE (BASIC) ...........................................................................16

1. Item data setting ............................................................................................................................................ 16

2. Checking the contour of a sewing pattern .................................................................................................. 19

3. Sewing ............................................................................................................................................................ 20

4. Change to the other sewing pattern ............................................................................................................. 20

5. Winding a bobbin ........................................................................................................................................... 21

6. Thread clamp device ..................................................................................................................................... 22

[6] OPERATION OF THE SEWING MACHINE (ADVANCED) ..................................................................24

1. Performing sewing using the pattern keys ( , , , and ) ....................................................... 24

2. Performing sewing using the combination function .................................................................................. 27

3. Performing sewing using the “bobbin thread counter” ............................................................................. 29

4. How to use the temporary stop .................................................................................................................... 29

5. Setting the pattern thread tension ............................................................................................................... 30

6. Cautions in operation .................................................................................................................................... 31

[7] MAINTENANCE ................................................................................................................................... 31

1. Adjusting the height of the needle bar ........................................................................................................ 31

2. Adjusting the needle-to-shuttle relation ...................................................................................................... 32

3. Adjusting the lift of the work clamp foot ..................................................................................................... 33

4. The moving knife and counter knife............................................................................................................. 33

5. Needle thread clamp device .......................................................................................................................... 34

6. Adjustment of the wiper ................................................................................................................................ 34

7. Draining waste oil .......................................................................................................................................... 35

8. Amount of oil supplied to the hook .............................................................................................................. 35

9. Replacing the fuse ......................................................................................................................................... 35

10. Changing the voltage of 100/200V ................................................................................................................ 36

11. Replenishing the designated places with grease ....................................................................................... 37

[8] HOW TO USE THE MEMORY SWITCH ............................................................................................... 38

1. Start and change of the memory switch ...................................................................................................... 38

2. Example of the memory switch setting ....................................................................................................... 38

3. Table of functions of the memory switch .................................................................................................... 42