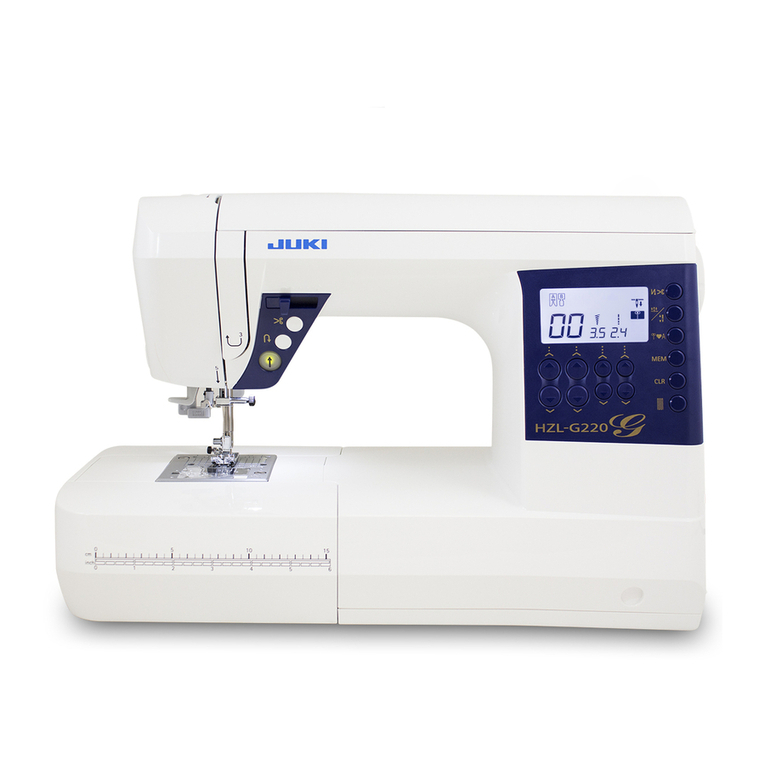

Auxiliary table

(standard accessory)

LED light

(Provided as standard)

17mm

by Digitization

Excellent operability by Digitization

Excellent seam quality

Many functions of the pedal.

The machine is provided as standard with a newly-developed auto-lifter driven by a stepping motor. This helps reduce the operator's fatigue.

As for the pedal, one-pedal and two-pedal models can both be changed over and the intermediate stop, which facilitates positioning of the

sewing product, can be specified.

The work clamp foot lift can be set as desired. The reverse-rotation needle-up function offers a maximum work clamp foot lift of 17mm.

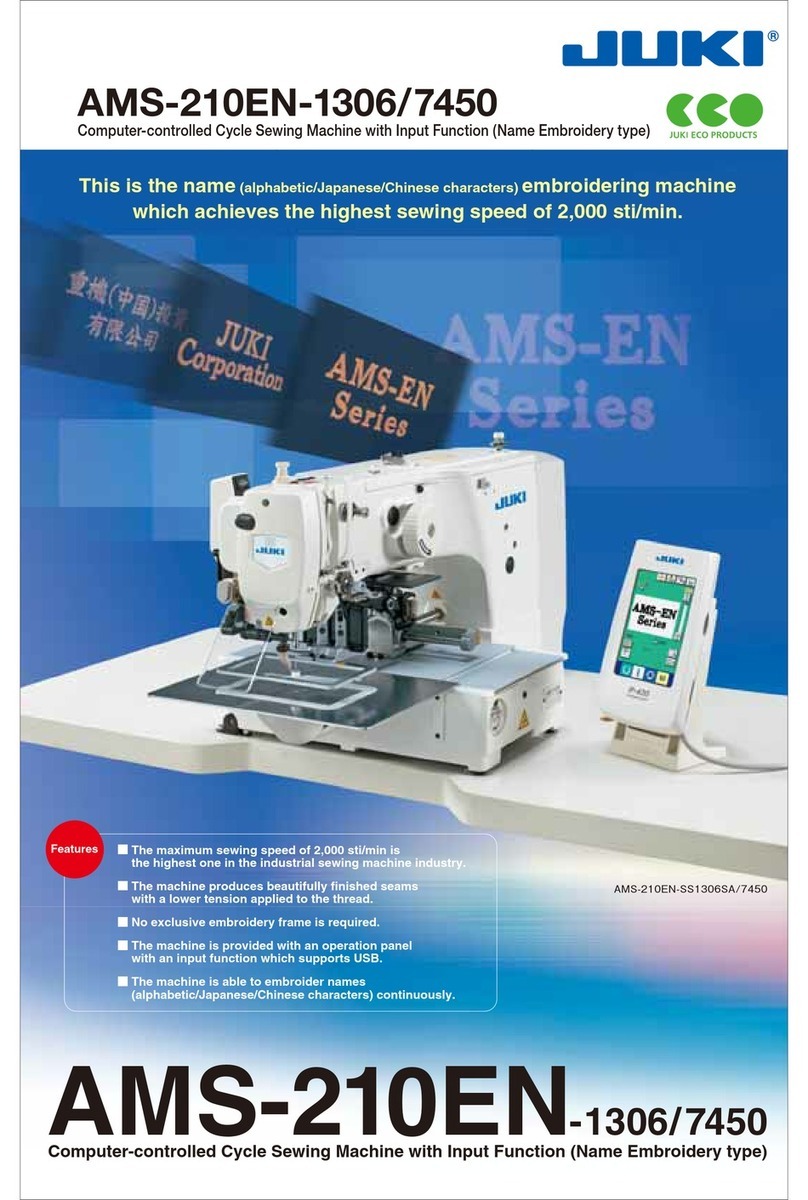

Higher productivity

Cycle sewing and continuous sewing.

All drive mechanisms are electronically controlled

Operator-friendly environment

The maximum sewing speed is 4,200 sti/min., and the jump speed

is 200 mm/s. The cycle time has been further reduced for continuous

sewing.

Electronic control of the material feed mechanism, needle feed

mechanism, needle thread trimming mechanism, bobbin thread

trimming mechanism, cloth trimming mechanism, presser lifter

mechanism and other mechanisms has been achieved.

All adjustment values are digitalized to enable the operator to set

and store those values on the operation panel.

Operation with reduced noise is ensured by the adoption of the

direct-drive motor.

The illuminance of the LED light is adjustable and is located on the

underside of the arm jaw. It is provided as standard for all models of

the LBH-1790A Series.

The sewing product can further be placed on the machine easily by

installing the auxiliary table (standard accessory). In addition, the

needle entry is located in the center of the bed, promising easier

positioning of the sewing product.

Twenty different programs can be registered, and as many as 15

different patterns can be stored in one program.

Cycle sewing

The machine is able to continuously sew two or more different

patterns without requiring the work clamp foot to be lifted. As may as

20 programs can be registered, and six different patterns can be

stored in one program. (Related parts need to be exchanged for

optional ones.)

Continuous sewing

JUKI's unique active tension (Electronic thread tension control system).

Basting stitchWithout basting stitch With basting stitch

(The state in which the material is stretched in

the lengthwise direction after buttonholing)

Finished state of

double stitching

State of firstround

stitch

Whip stitchingPurl stitching

Needle thread tension for sewing parallel and bartacking sections of buttonholes

can be separately controlled through the operation panel and stored in memory

according to various sewing conditions (e.g., type of thread, type of material and

sewing speed).

The basting stitch is effective on elastic materials such as knits.

Basting stitch: Since the needle thread is tucked in without fail, it will

never jut out of the buttonhole seams.

Basting stitch can be sewn by nine rounds.

The machine is able to change the needle thread tensions at the parallel and

bartacking sections of the buttonhole, to produce a beautiful buttonhole shape.

This capability helps greatly in preventing thread breakage.

Needle thread tension is activated at the beginning and end of sewing. This

prevents unthreading of the needle thread, and thread fraying that is likely to

occur at the beginning of sewing.

Thread tension for basting stitching can be specified separately.

(For a changeover between purl stitch

and whip stitch, threading of bobbin,

as well as the bobbin thread tension

need to be changed.)

For double stitching, the bartacking section

is skipped and only the parallel sections are

sewn twice. This prevents any excessively

tight finishes in the bartacking section of the

buttonhole.

First- and second-round stitches can be

sewn using different stitch widths.

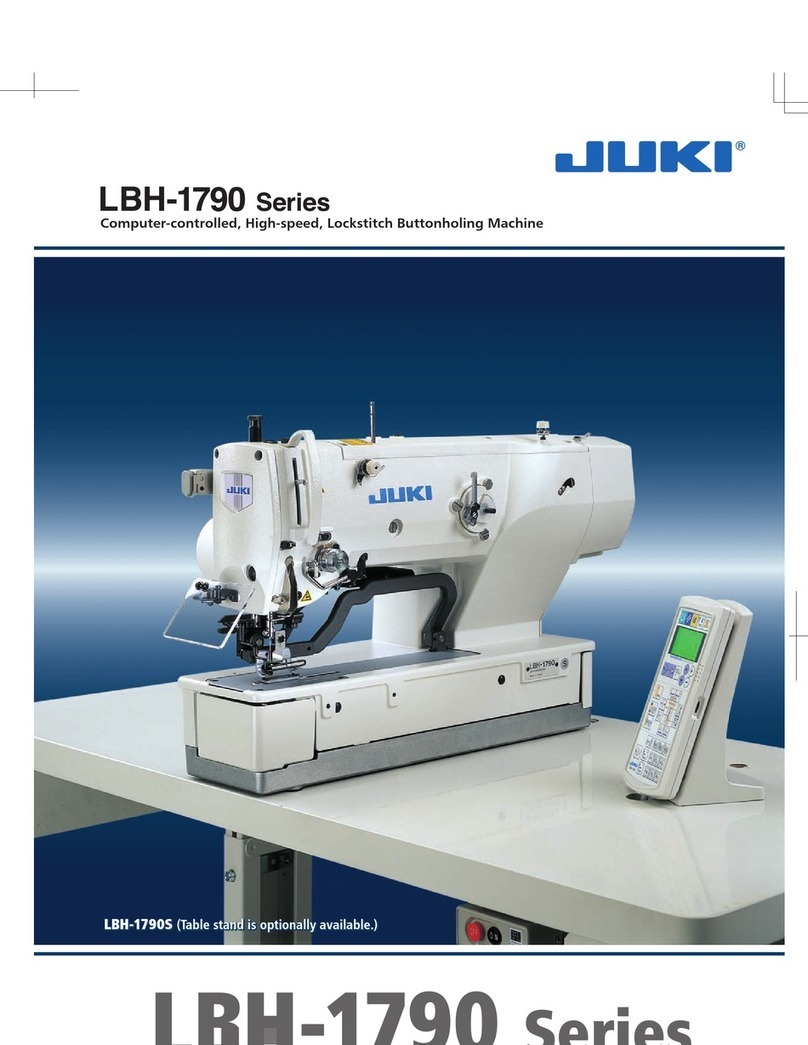

The LBH-1790A Series follows the world's highest sewing speed and dry-head mechanism

of its predecessor model. In addition, this machine comes with the latest model

operation panel which is installed with a USB port.

Furthermore, all drive mechanisms have been digitalized to

manage each sewing pattern individually.

LBH-1790A Series

LBH-1790AS

Solenoid Needle thread tensioner

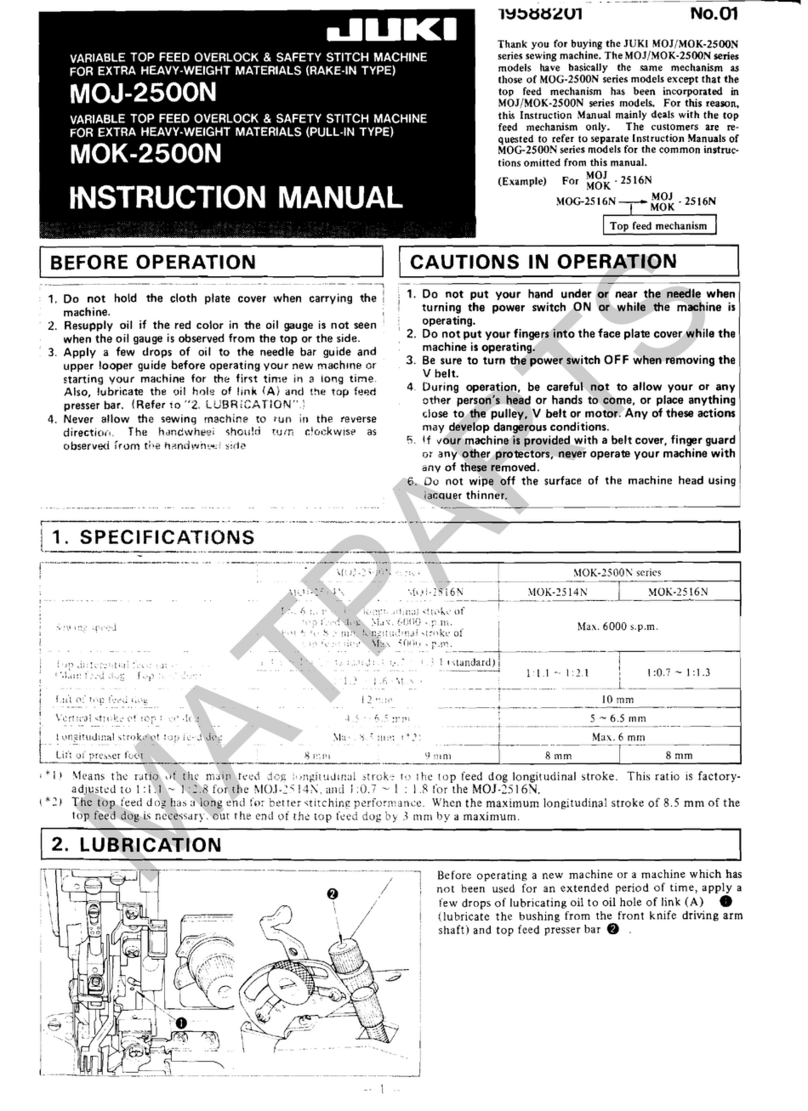

Explanation of pedal motion

Pedal motion

Initial position ②Intermediate position ①Maximum position ①Maximum position

Setting of

sewing product

Start of sewing

End of sewing

Pedal type

2-pedal 1-pedal 1-pedal

The right side pedal is depressed.

The second step of the right side pedal

The third step of the right side pedal

②Presser automatically goes up to

intermediate position.

①Presser automatically goes up to

maximum position.

①Presser automatically goes up to

maximum position.

Work clamp

position

Cloth

③

②

①

Sewing position

Intermediate position

Maximum position

(without intermediate position) (with intermediate position)

Presser goes up as high as the pedal

toe down amount of the left side

pedal. Presser comes down when the

left side pedal is depressed.

→③ Sewing position

The first step of the right side pedal

→③ Sewing position

The first step of the right side pedal

→② Intermediate position

The second step of the right side pedal

→③ Sewing position

Basting stitch mechanism is effective

for the production of beautiful buttonholes.

Sewing settings can be easily changed.

Thanks to the multiple knife-dropping function, it is no longer

required that the knife be changed at the time the buttonhole size is

changed. The number of knife dropping times can be automatically

set according to the buttonholing size in cases where the buttonhole

size is frequently changed for small-lot productions or during the

cycle sewing of buttonholes that are different in size.

The double-acting stepping motor type knife mechanism is free from

the faulty dropping/returning of the knife. In addition, the knife

pressure can be changed according to the material to be sewn.

The knife supports sewing lengths of 41mm at the maximum. In

addition, knife mechanisms for 70mm and 120mm are optionally

available.

The machine is equipped

with a multiple knife-dropping function.

Whip stitchingPurl stitching Double stitchingSingle stitching