V1.00/EN/00709718 [Thyristor power switch TYA S201] 3

contents

1 Introduction..................................................................................7

1.1 Preface ........................................................................................................ 7

1.2 Typographical conventions ....................................................................... 8

1.2.1 Warning symbols ................................................................................................. 8

1.2.2 Note symbols ....................................................................................................... 9

1.2.3 Performing an action ........................................................................................... 9

1.2.4 Display types ........................................................................................................ 9

1.3 Order details ............................................................................................. 10

1.3.1 Scope of delivery ............................................................................................... 10

1.3.2 Accessories ........................................................................................................ 10

1.3.3 General accessories .......................................................................................... 11

1.4 Brief description ....................................................................................... 12

1.5 Standards, approvals, and conformity ................................................... 13

2 Mounting ....................................................................................15

2.1 Important installation notes .................................................................... 15

2.1.1 Environmental influences .................................................................................. 16

2.1.2 Filtering and interference suppression ............................................................ 17

2.1.3 Admissible load current depending

on the ambient temperature and the site altitude .......................................... 17

2.1.4 Wall mounting with screws (per default) ......................................................... 19

2.1.5 Fastening on DIN rail (accessories) ................................................................. 22

2.2 Dimensions ............................................................................................... 23

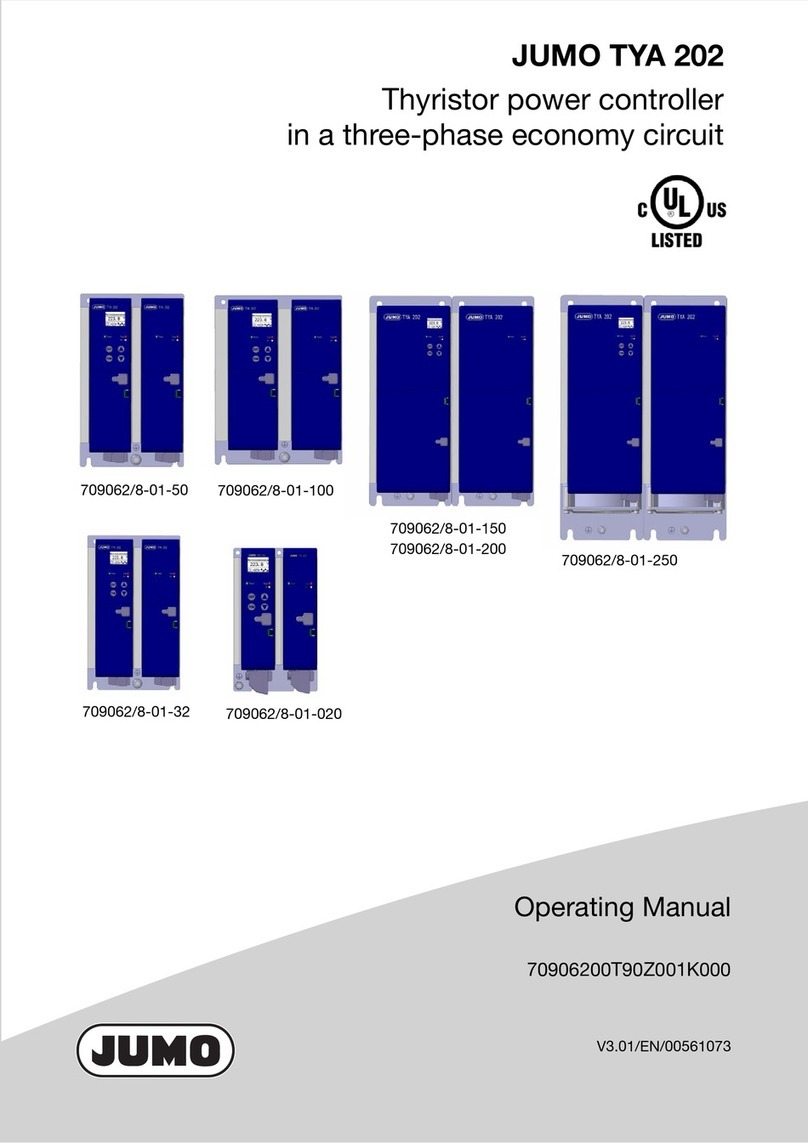

2.2.1 Type 709065/X-0X-020-0X-XXX-XX .................................................................. 23

2.2.2 Type 709065/X-0X-032-0X-XXX-XX .................................................................. 23

2.2.3 Type 709065/X-0X-050-0X-XXX-XX .................................................................. 24

2.2.4 Type 709065/X-0X-100-0X-XXX-XX .................................................................. 24

2.2.5 Type 709065/X-0X-150-0X-XXX-XX

Type 709065/X-0X-200-0X-XXX-XX .................................................................. 25

2.2.6 Type 709065/X-0X-250-0X-XXX-XX ................................................................. 26

2.2.7 Clearances (all types) ........................................................................................ 26

3 Electrical connection ................................................................27

3.1 Pluggable screw terminals with 20 A ..................................................... 27