- 3

The waste water with oil content is pumped

using a dirt water pump (14) and/or a dirt

collector attachment set from the dirt collect

(1) into the reaction tank (3) of the plant.

Depending on the pre-set operations type,

the following takes place in the reaction

tank:

If you use liquid splitting agent:

– Add liquid splitting agent from the dos-

ing unit (4) whereby the dosing quantity

needs to be adjusted to match the level

of dirt in the waste water.

– Homogenous mixing of splitting agent

and waste water by stirring and circula-

tion using the bypass pump (18).

– Formation of flakes when dirt binds with

emulgated oil.

– Pumping the mixture of flakes and puri-

fied water to the recycling filter (7) using

the emptying pump for liquid splitting

agent (16). From there, it ultimately

reaches the storage tank for processed

water (9).

If you use liquid splitting powder:

– Add splitting powder from the dosing

unit (5) whereby the dosing quantity

needs to be adjusted to match the level

of dirt in the waste water.

– Homogenous mixing of splitting powder

and waste water by stirring and circula-

tion using the bypass pump (18).

– Formation of flakes when dirt binds with

emulgated oil.

– Use the emptying pump for splitting

powder (17) to pump the mixture of

flakes and cleaned water to the filter for

splitting powder (8). Depending on the

operations type that has been set, it will

then go from there via the waste water

cock (13) to the waste water drainage

system or via a connection hose be-

tween the waste water cock (13) and

the drainage cock (10) to the storage

tank for processed water (9).

Depending on the installation version,

the purified waste water from the stor-

age tank for processed water can be

used as follows:

– Pump the purified water to an external

buffer tank (optional) iva the drain cock

for processed water (19) using the sup-

ply pump for high-pressure cleaner for

further use at a later stage.

– Pump the purified water to a high-pres-

sure cleaner using the high-pressure

cleaner supply pump (12) via the drain

cock for processed water (19) and link-

ing it through the control pipe of the

ASA/HDS attachment set.

Alternately, the plant can also be con-

nected to a high-pressure cleaner via

the HDS - ASA/HDR and the fresh wa-

ter remote conrol attachment set.

In the two recycling versions, water scarcity

(caused by carrying and evaporation) is

balanced out through fresh water supply.

The fresh water can be used for rinsing

processes if the HDS - ASA/HDR attach-

ment set is used.

Sterilisation agent (6) must be added via

the dosing container (6) to regain washing

water. This can help in avoiding bad odour

due to formation of bacteria.

Optionally, you can also install a floater

switch in the dirt collector to prevent over-

flowing. When the floater switch is activat-

ed (dirt collector is full), the water supply to

the high-pressure cleaner is blocked. This

takes place till the floater switch in the dirt

collector releases the system again.

Note: The plant is to be installed and start-

ed only by Kärcher or a dealer trained by

Kärcher.

See "Plant Installation" for installation in-

structions.

Danger

Risk due to irritating/ caustic chemicals that

can cause serious injury to skin and eyes.

Therefore: Do not eat, drink or smoke.

Wear personal safety gear:

– Hand protection: Rubber gloves

– Eye protection: Safety goggles

– Protection for body: Overalls

Ensure proper ventilation!

First aid!

– After skin contact: immediately rinse

with water; then clean with soap.

– After coming in contact with eyes: rinse

with water immediately (15 minutes);

consult the doctor.

– After swallowing in: immediately rinse

the mouth with lots of water or drink lots

of water (see EG safety data sheet); do

no induce vomitting; consult a doctor.

– After breathing in: Breath in fresh air;

clear the respiratory path.

Danger

Danger of crushing on account of the dos-

ing equipment. Top up splitting agent only

when the plant is switched off.

Caution

Damage to the plant due to wrong chemi-

cals. Only use the chemicals that have

been approved and recommended by the

manufacturer.

The treatment chemicals are added in var-

ying proportions depending on the opera-

tions model and area of use.

– Use only in models where splitting pow-

der is to be used.

ÎFill in the splitting powder up to maxi-

mum 2/3 of the container. Comply with

safety regulations on the handling of

splitting powder.

– Use only in models where liquid splitting

agent is to be used.

– RM 847 mmust be prepared according

to details on the label or on the product

info sheet. RM 847 must always be di-

luted and used fresh because the dilut-

ed solution is not stable over a longer

period of time.

ÎFill in the prepared splitting agent solu-

tion into the container. Comply with

safety regulations for handling RM 847.

– For all operation types where washing

water is reused.

ÎFill the sterilisation agent in the mixing

unit container provided for the purpose.

Follow the safety instructions of the

manufacturer of the sterilisation agent.

Note:The dosing quantities of the above-

mentioned product are set at the factory to

an average value! The dosing quantities

must be adjusted by the Customer Service

mechanic at the installation site at the time

of start-up to match the level of dirt in the

waste water.

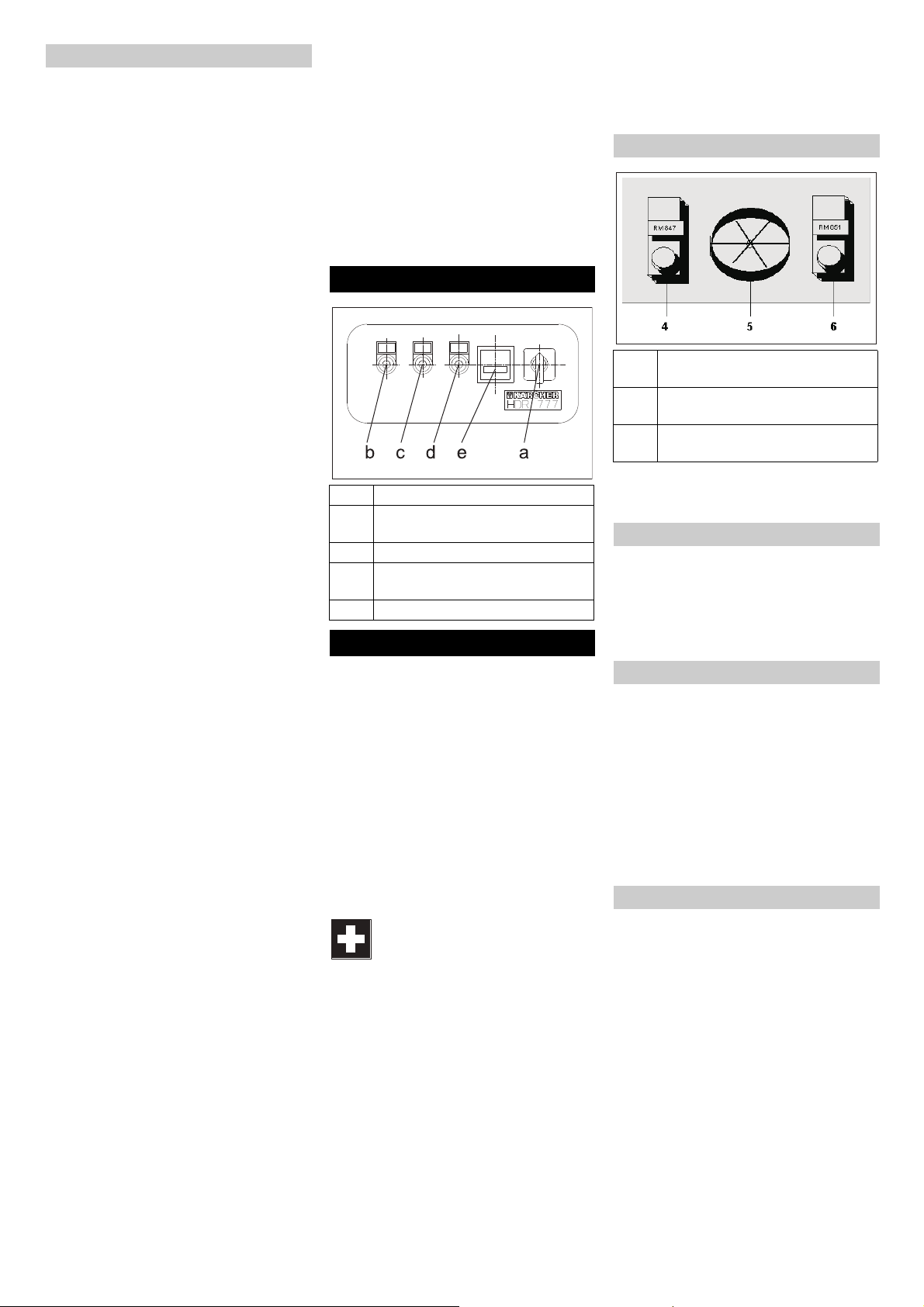

Functional description

Control elements

a Main switch

b Indicator lamp "Operations"

(green)

C Indicator lamp "Fault" (red)

d Indicator lamp "Splitting process

On" (green)

E Operating hour counter

Start up

Chemicals and dosing equipment

4 Dosing container for liquid splitting

agent RM 847

5 Dosing unit for powder splitting

agent RM 846

6 Dosing container for sterilisation

agent RM 851

Splitting powder RM 846

Liquid splitting agent RM 847

Sterilisation agent RM 851

14 EN