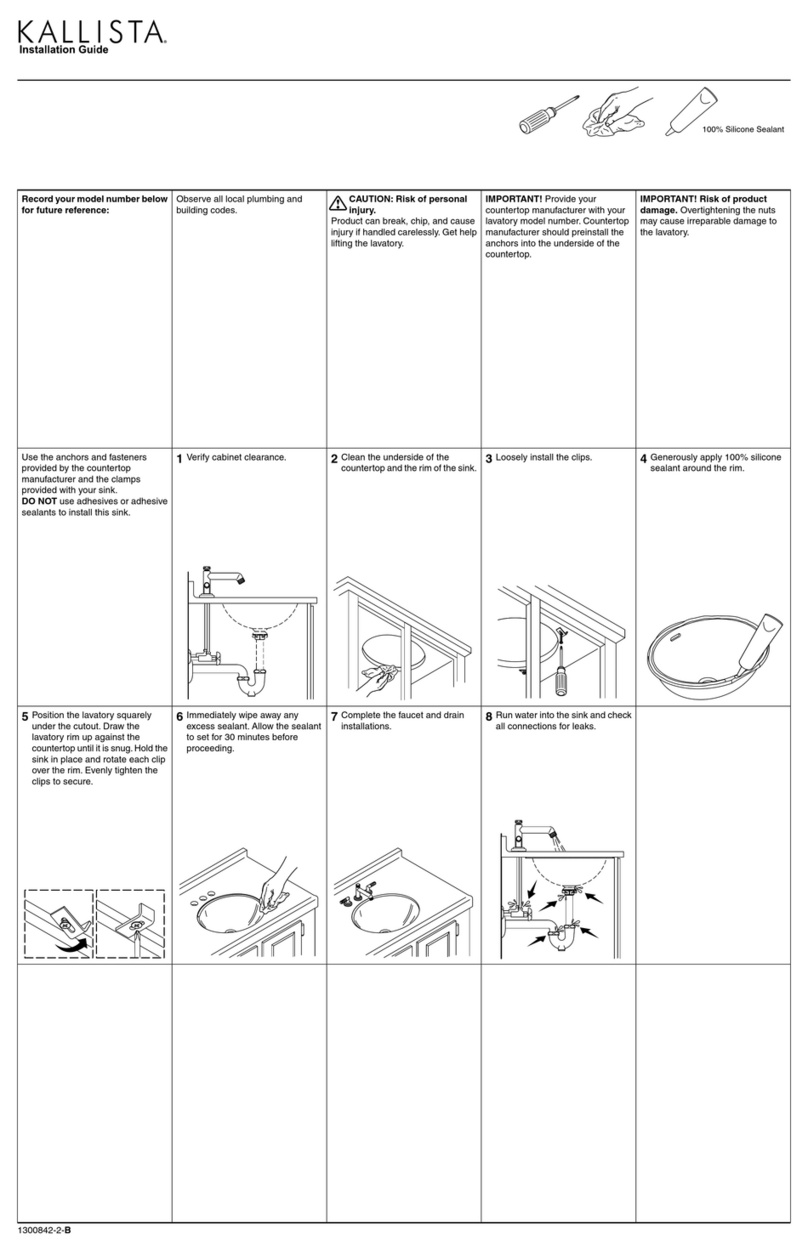

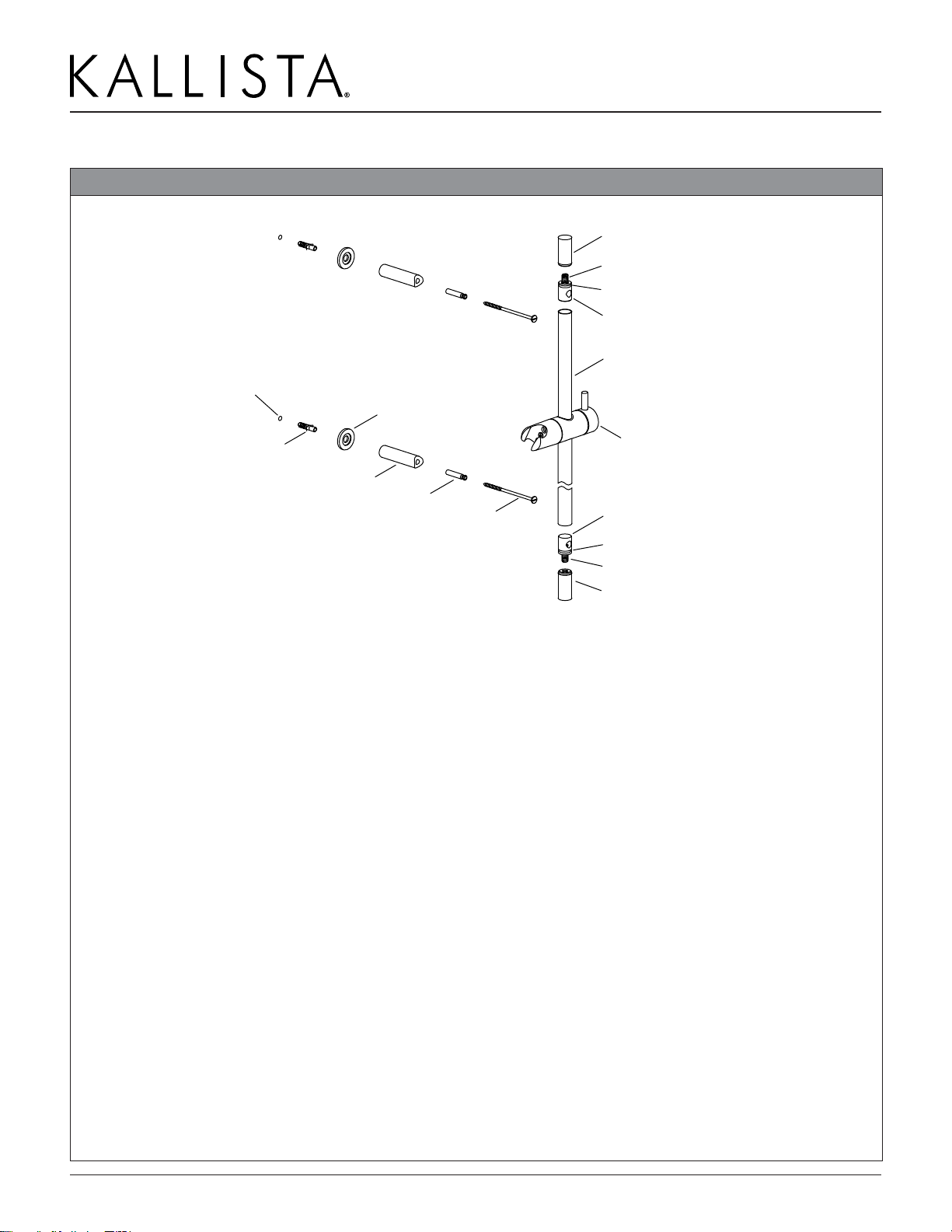

100% Silicone Sealant Sealant Tape Strap Wrench

Important Information

Follow all local plumbing and building

codes.

Shut off the water supply.

NOTICE: Choose an automatic

compensating valve with the appropriate

minimum flow rating, to assure your

valve will provide safety at the lowest

flow rates. For a showerhead with a

maximum flow rate of 1.75 gal/min (6.6

l/min), use with an automatic

compensating valve rated 1.5 gal/min

(5.7 l/min) or less.

IMPORTANT INSTRUCTIONS

Before using your shower, verify your

new showerhead is compatible with

your shower valve (located behind the

wall) by performing the following steps:

• While standing outside the shower,

turn on the shower valve. Do not step

into the shower.

• Adjust the water to your typical

showering temperature.

• Have someone flush the nearest toilet.

• With your hand, carefully check the

water temperature, from the

showerhead while the toilet is refilling.

• If the water becomes significantly

hotter, you will need to either replace

the shower valve with a compatible

KALLISTA valve or return your

showerhead.

CAUTION: Risk of scalding.

KALLISTA low-flow showerheads

are designed for use with compatible

KALLISTA valves. When installing a

low-flow product to an existing

showering system, verify compatibility

before showering. Do not use this

KALLISTA low-flow product with a

shower valve that allows the water

temperature to become too hot when

other plumbing products are used.

CAUTION: Risk of product

damage.

To avoid plugging the showerhead

spray outlets, use thread sealant tape

on the shower arm threads. Do not use

thread sealant compound (pipe dope).

Record your model number.

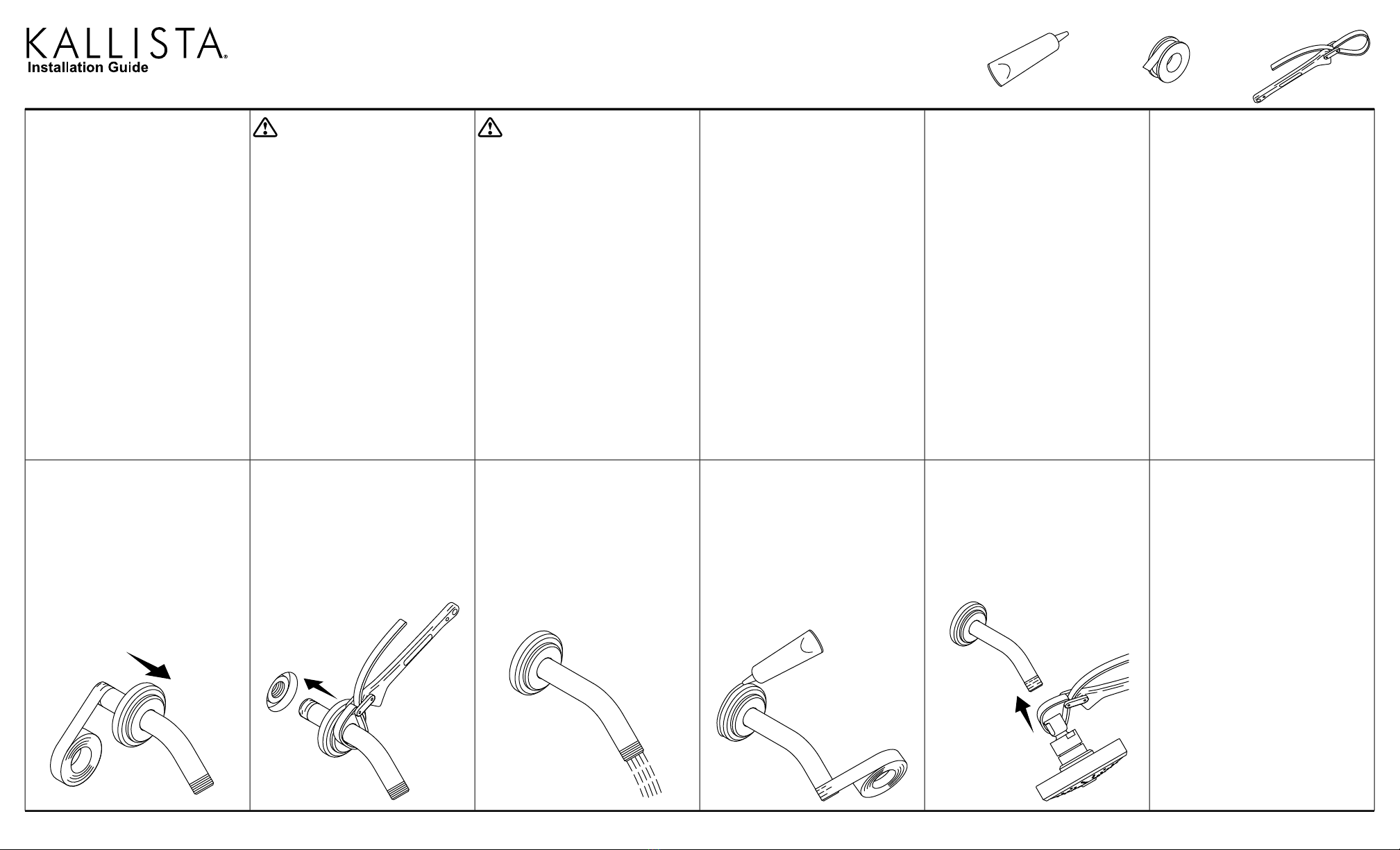

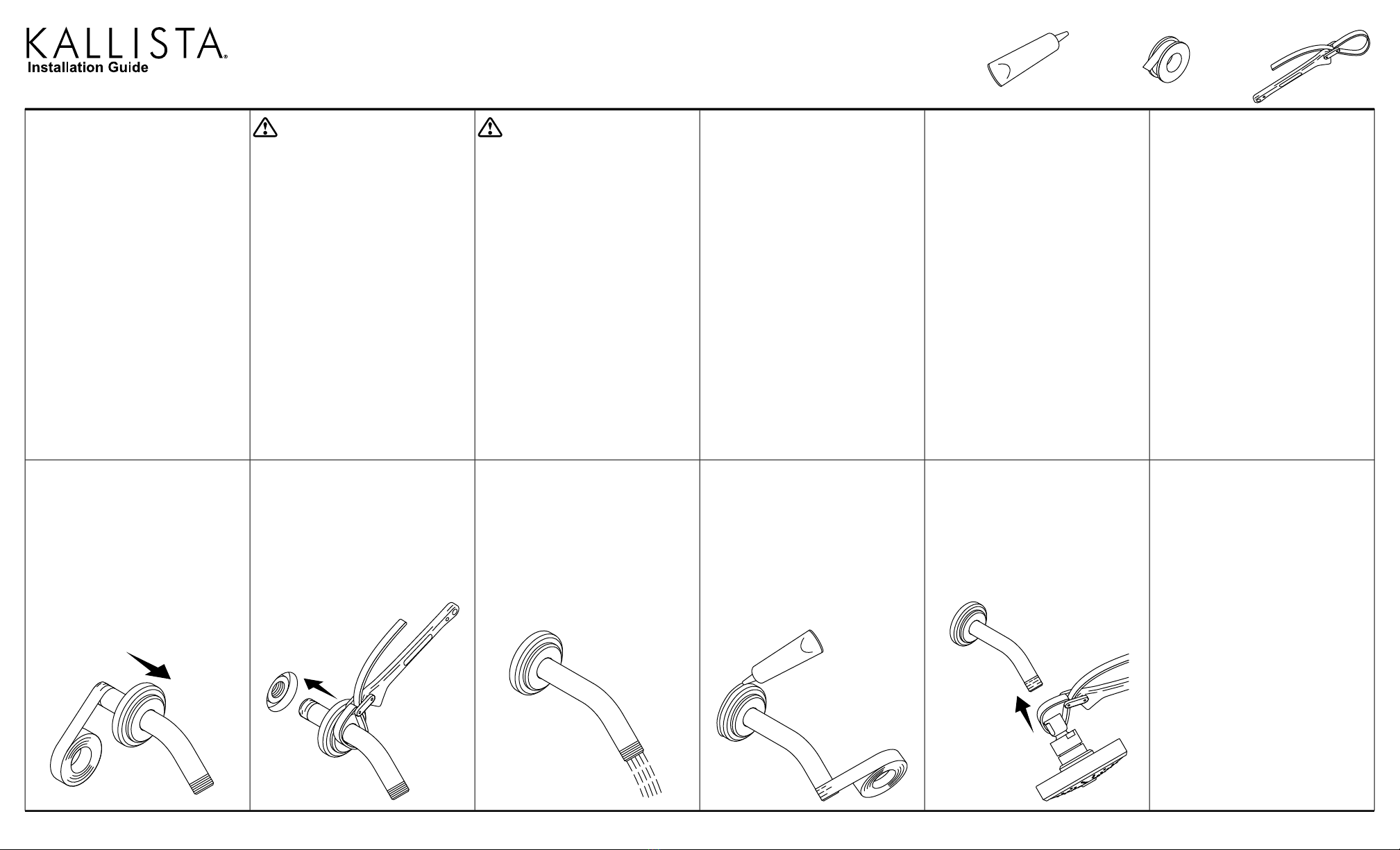

5Use a clean strap wrench to secure

the showerhead to the arm.

4Apply 100% silicone sealant around

the wall plate. Apply sealant tape to

the arm.

3Slide the plate against the wall. Run

water to flush debris.

2Install the arm. Tighten with a clean

strap wrench.

1Slide the wall plate onto the shower

arm. Apply sealant tape.

1333673-2-C