4

1

5

8

10

12

11

2

3

7

6

9

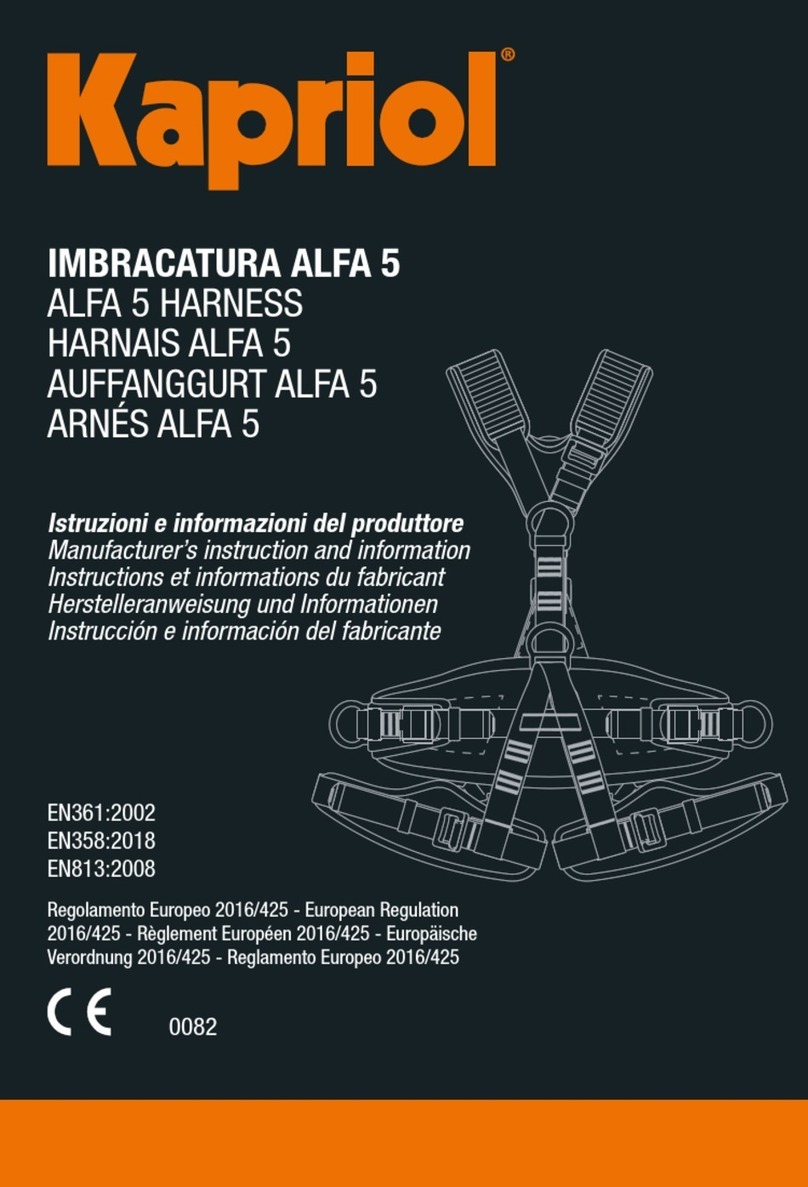

FULL BODY HARNESS

Ref. 27905

Size:

S-L

XXL

COMBI

Date of manufacture:

MM.YYYY

Serial number:

XXX XXX

b

ac

efghi

j

EN 358:2018

EN 361:2002

k

d

70 - 110 cm

l

3

EN 358

HOW TO PUT ON THE HARNESS

6 7 8

1

2 3 4

Take the harness by the back attaching

buckle.

Connect front plastic clip and adjust

the tension the chest strap.

Pull one and then other thigh straps

through crottch, take care do not twist

them.

Connecting of the steel buckles of the thigh straps and work positioning belt

Regulation of the thigh straps and work positioning belt

Put on the shoulder straps one after one,

take care do not twist them.

Shortening Lengthening

THE ESSENTIAL PRINCIPLES FOR USERS OF PERSONAL PROTECTIVE EQUIPMENT AGAINST FALLS FROM A HEIGHT:

!personal protective equipment shall only be used by a person trained and competent in its safe use.

!personal protective equipment must not be used by a person with medical condition that could affect the safety of the equipment user in normal and emergency use.

!a rescue plan shall be in place to deal with any emergencies that could arise during the work.

!being suspended in PPE (e.g. arresting a fall), beware of suspension trauma symptoms.

!to avoid symptoms of suspension trauma, be sure that the proper rescue plan is ready for use. It is recommended to use foot straps.

!it is forbidden to make any alterations or additions to the equipment without the manufacturer's prior written consent.

!any repair shall only be carried out by equipment manufacturer or his certified representative.

!personal protective equipment shall not be used outside its limitations, or for any purpose other than that for which it is intended.

!personal protective equipment should be a personal issue item.

!before use ensure about the compatibility of items of equipment assembled into a fall arrest system. Periodically check connecting and adjusting of the equipment

components to avoid accidental loosening or disconnecting of the components.

!it is forbidden to use combinations of items of equipment in which the safe function of any one item is affected by or interferes with the safe function of another.

!before each use of personal protective equipment it is obligatory to carry out a pre-use check of the equipment, to ensure that it is in a serviceable condition and operates

correctly before it is used.

!during pre-use check it is necessary to inspect all elements of the equipment in respect of any damages, excessive wear, corrosion, abrasion, cutting or incorrect acting,

especially take into consideration:

- in full body harnesses and belts - buckles, adjusting elements, attaching points, webbings, seams, loops;

- in energy absorbers - attaching loops, webbing, seams, casing, connectors;

- in textile lanyards or lifelines or guidelines - rope, loops, thimbles, connectors, adjusting element, splices;

- in steel lanyards or lifelines or guidelines - cable, wires, clips, ferrules, loops, thimbles, connectors, adjusting elements;

- in retractable fall arresters - cable or webbing, retractor and brake proper acting, casing, energy absorber, connector;

- in guided type fall arresters - body of the fall arrester, sliding function, locking gear acting, rivets and screws, connector, energy absorber;

- in metalic components (connectors, hooks, anchors) - main body, rivets, gate, locking gear acting.

!after every 12 months of utilization, personal protective equipment must be withdrawn from use to carry out periodical detailed inspection. The periodic inspection must be

carried out by a competent person for periodic inspection. The periodic inspection can be carried out also by the manufacturer or his authorized representative.

!in case of some types of the complex equipment e.g. some types of retractable fall arresters the annual inspection can be carried out only by the manufacturer or his

authorized representative.

!regular periodic inspections are the essential for equipment maintenance and the safety of the users which depends upon the continued efficiency and durability of the

equipment.

!during periodic inspection it is necessary to check the legibility of the equipment marking. Don’t use the equipment with the illegible marking.

!it is essential for the safety of the user that if the product is re-sold outside the original country of destination the reseller shall provide instructions for use, for

maintenance, for periodic examination and for repair in language of the country in which the product is to be used.

!personal protective equipment must be withdrawn from use immediately when any doubt arise about its condition for safe use and not used again until confirmed in writing

by equipment manufacturer or his representative after carried out the detailed inspection.

!personal protective equipment must be withdrawn from use immediately and destroyed (or another procedures shall be introduced according detailed instruction from

equipment manual) when it have been used to arrest a fall.

PERIODIC INSPECTIONS

Safety harness must be inspected at least once every 12 months from

the date of first use. Periodic inspections must only be carried out by a

competent person who has the knowledge and training required for

personal protective equipment periodic inspections. Depending upon

the type and environment of work, inspections may be needed to be

carried out more frequently than once every 12 months.

MAXIMUM LIFESPAN OF THE EQUIPMENT

The maximum lifespan of the harness is 10 years from the date of

manufacture.

ATTENTION: The harness maximum lifetime depends on the intensity

of usage and the environment of usage. Using the harness in rough

environment, marine environment, contact with sharp edges, exposure

to extreme temperatures or aggressive substances, etc. can lead to the

withdrawal from use even after one use.

WITHDRAWAL FROM USE

The harness must be withdrawn from use immediately and destroyed

when it has been used to arrest a fall or it fails to pass inspection or

there are any doubt as to its reliability.

Every periodic

inspection must be recorded in the Identity Card of the equipment.

1.1 1.2 2.1

2.2

1.3

ATTACHING FALL ARRESTS SYSTEMS – EN361

Fall arrest system can be attached only to the fall arrest attachment point of full body harness EN 361 marked with capital letter A:

- directly to the back D-ring (1.1)

- to the front attachment loops. The loops marked with a half of letter must be linked together when attached to the fall arrest

system (1.2). It is strictly forbidden to attach a fall arrest system to a single loop with a half of letter A (1.3).

Harness is put on correctly if:

- All straps are correctly adjusted (neither too loose nor too tight).

- Dorsal attachment D-ring is correctly positioned at the shoulder blades.

- The ends of the all straps are secured with flexible loops.

NOTE: Before using the belt for the first time

the user should carry out a suspension test

in a safe place to ensure that the sit harness

has correct size, is properly adjusted and is of an

acceptable comfort level for the intended use.

It’s important to check the sit harness regularly

for any damage.

WARNING!

It is strictly forbidden to attach any fall arrest system to lateral buckle of the work positioning belt during work.

ATTACHING WORK POSITIONING/RESTRAINT SYSTEM (EN 358)

- waist belt should not be used if there is a foreseeable risk of the user becoming

suspended or being exposed to unintended tension by the waist belt

- when using a work positioning system, the user normally relies on the equipment for

support, therefore it is essential to consider the need of using a back-up, e.g. a fall arrest

system

- Work positioning or restraint system can be attached to lateral buckles of the work

positioning belt (3)

- Work positioning lanyard must be attached on a structural point located at the user's

waist or above and kept taut.

A/2 A/2

A/2

2.1

2.3

4

1

5

8

10

12

11

2

3

7

6

9

FULL BODY HARNESS

Ref. 27905

Size:

S-L

XXL

COMBI

Date of manufacture:

MM.YYYY

Serial number:

XXX XXX

b

ac

efghi

j

EN 358:2018

EN 361:2002

k

d

70 - 110 cm

l

3

EN 358

HOW TO PUT ON THE HARNESS

6 7 8

1

9 10

5

2 3 4

Take the harness by the back attaching

buckle.

Connect front plastic clip and adjust

the tension the chest strap.

Pull one and then other thigh straps

through crottch, take care do not twist

them.

Connecting of the steel buckles of the thigh straps and work positioning belt

Regulation of the thigh straps and work positioning belt

Put on the shoulder straps one after one,

take care do not twist them.

Shortening Lengthening

THE ESSENTIAL PRINCIPLES FOR USERS OF PERSONAL PROTECTIVE EQUIPMENT AGAINST FALLS FROM A HEIGHT:

!personal protective equipment shall only be used by a person trained and competent in its safe use.

!personal protective equipment must not be used by a person with medical condition that could affect the safety of the equipment user in normal and emergency use.

!a rescue plan shall be in place to deal with any emergencies that could arise during the work.

!being suspended in PPE (e.g. arresting a fall), beware of suspension trauma symptoms.

!to avoid symptoms of suspension trauma, be sure that the proper rescue plan is ready for use. It is recommended to use foot straps.

!it is forbidden to make any alterations or additions to the equipment without the manufacturer's prior written consent.

!any repair shall only be carried out by equipment manufacturer or his certified representative.

!personal protective equipment shall not be used outside its limitations, or for any purpose other than that for which it is intended.

!personal protective equipment should be a personal issue item.

!before use ensure about the compatibility of items of equipment assembled into a fall arrest system. Periodically check connecting and adjusting of the equipment

components to avoid accidental loosening or disconnecting of the components.

!it is forbidden to use combinations of items of equipment in which the safe function of any one item is affected by or interferes with the safe function of another.

!before each use of personal protective equipment it is obligatory to carry out a pre-use check of the equipment, to ensure that it is in a serviceable condition and operates

correctly before it is used.

!during pre-use check it is necessary to inspect all elements of the equipment in respect of any damages, excessive wear, corrosion, abrasion, cutting or incorrect acting,

especially take into consideration:

- in full body harnesses and belts - buckles, adjusting elements, attaching points, webbings, seams, loops;

- in energy absorbers - attaching loops, webbing, seams, casing, connectors;

- in textile lanyards or lifelines or guidelines - rope, loops, thimbles, connectors, adjusting element, splices;

- in steel lanyards or lifelines or guidelines - cable, wires, clips, ferrules, loops, thimbles, connectors, adjusting elements;

- in retractable fall arresters - cable or webbing, retractor and brake proper acting, casing, energy absorber, connector;

- in guided type fall arresters - body of the fall arrester, sliding function, locking gear acting, rivets and screws, connector, energy absorber;

- in metalic components (connectors, hooks, anchors) - main body, rivets, gate, locking gear acting.

!after every 12 months of utilization, personal protective equipment must be withdrawn from use to carry out periodical detailed inspection. The periodic inspection must be

carried out by a competent person for periodic inspection. The periodic inspection can be carried out also by the manufacturer or his authorized representative.

!in case of some types of the complex equipment e.g. some types of retractable fall arresters the annual inspection can be carried out only by the manufacturer or his

authorized representative.

!regular periodic inspections are the essential for equipment maintenance and the safety of the users which depends upon the continued efficiency and durability of the

equipment.

!during periodic inspection it is necessary to check the legibility of the equipment marking. Don’t use the equipment with the illegible marking.

!it is essential for the safety of the user that if the product is re-sold outside the original country of destination the reseller shall provide instructions for use, for

maintenance, for periodic examination and for repair in language of the country in which the product is to be used.

!personal protective equipment must be withdrawn from use immediately when any doubt arise about its condition for safe use and not used again until confirmed in writing

by equipment manufacturer or his representative after carried out the detailed inspection.

!personal protective equipment must be withdrawn from use immediately and destroyed (or another procedures shall be introduced according detailed instruction from

equipment manual) when it have been used to arrest a fall.

PERIODIC INSPECTIONS

Safety harness must be inspected at least once every 12 months from

the date of first use. Periodic inspections must only be carried out by a

competent person who has the knowledge and training required for

personal protective equipment periodic inspections. Depending upon

the type and environment of work, inspections may be needed to be

carried out more frequently than once every 12 months.

MAXIMUM LIFESPAN OF THE EQUIPMENT

The maximum lifespan of the harness is 10 years from the date of

manufacture.

A

TTENTION: The harness maximum lifetime depends on the intensity

of usage and the environment of usage. Using the harness in rough

environment, marine environment, contact with sharp edges, exposure

to extreme temperatures or aggressive substances, etc. can lead to the

withdrawal from use even after one use.

WITHDRAWAL FROM USE

The harness must be withdrawn from use immediately and destroyed

when it has been used to arrest a fall or it fails to pass inspection or

there are any doubt as to its reliability.

Every periodic

inspection must be recorded in the Identity Card of the equipment.

1.1 1.2 2.1

2.2

1.3

ATTACHING FALL ARRESTS SYSTEMS – EN361

Fall arrest system can be attached only to the fall arrest attachment point of full body harness EN 361 marked with capital letter A:

- directly to the back D-ring (1.1)

- to the front attachment loops. The loops marked with a half of letter must be linked together when attached to the fall arrest

system (1.2). It is strictly forbidden to attach a fall arrest system to a single loop with a half of letter A (1.3).

Harness is put on correctly if:

- All straps are correctly adjusted (neither too loose nor too tight).

- Dorsal attachment D-ring is correctly positioned at the shoulder blades.

- The ends of the all straps are secured with flexible loops.

NOTE: Before using the belt for the first time

the user should carry out a suspension test

in a safe place to ensure that the sit harness

has correct size, is properly adjusted and is of an

acceptable comfort level for the intended use.

It’s important to check the sit harness regularly

for any damage.

WARNING!

It is strictly forbidden to attach any fall arrest system to lateral buckle of the work positioning belt during work.

ATTACHING WORK POSITIONING/RESTRAINT SYSTEM (EN 358)

- waist belt should not be used if there is a foreseeable risk of the user becoming

suspended or being exposed to unintended tension by the waist belt

- when using a work positioning system, the user normally relies on the equipment for

support, therefore it is essential to consider the need of using a back-up, e.g. a fall arrest

system

- Work positioning or restraint system can be attached to lateral buckles of the work

positioning belt (3)

- Work positioning lanyard must be attached on a structural point located at the user's

waist or above and kept taut.

A/2 A/2

A/2

2.1

2.3

HOW TO PUT ON THE HARNESS

1. Take the harness by the back-at-

taching buckle

2. Put on the shoulder straps one

after one, take care do not

twist them

3. Connect front plastic clip and

adjust the tension the chest strap

4. Pull one and then other thigh

straps through crotch, take care

do not twist them

Connecting of the steel buckles of

the thigh straps and work positio-

ning belt ( 5-6-7-8 )

Regulation of the thigh straps and work positioning belt ( 9-10 )

HARNESS IS PUT ON CORRECTLY IF:

- All straps are correctly adjusted (neither too loose nor too tight).

- Dorsal attachment D-ring is correctly positioned at the shoulder

blades.

- The ends of the all straps are secured with flexible loops.

PERIODIC INSPECTIONS

Safety harness must be inspected at least once every 12 months from the date of first use. Periodic

inspections must only be carried out by a

competent person who has the knowledge and training required for personal protective equipment

periodic inspections. Depending upon

the type and environment of work, inspections may be needed to be carried out more frequently

than once every 12 months.

MAXIMUM LIFESPAN OF THE EQUIPMENT

The maximum lifespan of the harness is 10 years from the date of manufacture.

ATTENTION: The harness maximum lifetime depends on the intensity of usage and the environment

of usage. Using the harness in rough environment, marine environment, contact with sharp edges,

exposure to extreme temperatures or aggressive substances, etc. can lead to the withdrawal from

use even after one use.

WITHDRAWAL FROM USE

The harness must be withdrawn from use immediately and destroyed when it has been used to

arrest a fall or it fails to pass inspection or

There is any doubt as to its reliability.

NOTE: Before using the belt for the first time the user should carry out a suspension test in a safe

place to ensure that the sit harness has correct size, is properly adjusted and is of an acceptable

comfort level for the intended use. It’s important to check the sit harness regularly for any damage.

4

1

5

8

10

12

11

2

3

7

6

9

FULL BODY HARNESS

Ref. 27905

Size:

S-L

XXL

COMBI

Date of manufacture:

MM.YYYY

Serial number:

XXX XXX

b

ac

efghi

j

EN 358:2018

EN 361:2002

k

d

70 - 110 cm

l

3

EN 358

HOW TO PUT ON THE HARNESS

6 7 8

5

2 3 4

Take the harness by the back attaching

buckle.

Connect front plastic clip and adjust

the tension the chest strap.

Pull one and then other thigh straps

through crottch, take care do not twist

them.

Connecting of the steel buckles of the thigh straps and work positioning belt

Regulation of the thigh straps and work positioning belt

Put on the shoulder straps one after one,

take care do not twist them.

Shortening Lengthening

THE ESSENTIAL PRINCIPLES FOR USERS OF PERSONAL PROTECTIVE EQUIPMENT AGAINST FALLS FROM A HEIGHT:

!personal protective equipment shall only be used by a person trained and competent in its safe use.

!personal protective equipment must not be used by a person with medical condition that could affect the safety of the equipment user in normal and emergency use.

!a rescue plan shall be in place to deal with any emergencies that could arise during the work.

!being suspended in PPE (e.g. arresting a fall), beware of suspension trauma symptoms.

!to avoid symptoms of suspension trauma, be sure that the proper rescue plan is ready for use. It is recommended to use foot straps.

!it is forbidden to make any alterations or additions to the equipment without the manufacturer's prior written consent.

!any repair shall only be carried out by equipment manufacturer or his certified representative.

!personal protective equipment shall not be used outside its limitations, or for any purpose other than that for which it is intended.

!personal protective equipment should be a personal issue item.

!before use ensure about the compatibility of items of equipment assembled into a fall arrest system. Periodically check connecting and adjusting of the equipment

components to avoid accidental loosening or disconnecting of the components.

!it is forbidden to use combinations of items of equipment in which the safe function of any one item is affected by or interferes with the safe function of another.

!before each use of personal protective equipment it is obligatory to carry out a pre-use check of the equipment, to ensure that it is in a serviceable condition and operates

correctly before it is used.

!during pre-use check it is necessary to inspect all elements of the equipment in respect of any damages, excessive wear, corrosion, abrasion, cutting or incorrect acting,

especially take into consideration:

- in full body harnesses and belts - buckles, adjusting elements, attaching points, webbings, seams, loops;

- in energy absorbers - attaching loops, webbing, seams, casing, connectors;

- in textile lanyards or lifelines or guidelines - rope, loops, thimbles, connectors, adjusting element, splices;

- in steel lanyards or lifelines or guidelines - cable, wires, clips, ferrules, loops, thimbles, connectors, adjusting elements;

- in retractable fall arresters - cable or webbing, retractor and brake proper acting, casing, energy absorber, connector;

- in guided type fall arresters - body of the fall arrester, sliding function, locking gear acting, rivets and screws, connector, energy absorber;

- in metalic components (connectors, hooks, anchors) - main body, rivets, gate, locking gear acting.

!after every 12 months of utilization, personal protective equipment must be withdrawn from use to carry out periodical detailed inspection. The periodic inspection must be

carried out by a competent person for periodic inspection. The periodic inspection can be carried out also by the manufacturer or his authorized representative.

!in case of some types of the complex equipment e.g. some types of retractable fall arresters the annual inspection can be carried out only by the manufacturer or his

authorized representative.

!regular periodic inspections are the essential for equipment maintenance and the safety of the users which depends upon the continued efficiency and durability of the

equipment.

!during periodic inspection it is necessary to check the legibility of the equipment marking. Don’t use the equipment with the illegible marking.

!it is essential for the safety of the user that if the product is re-sold outside the original country of destination the reseller shall provide instructions for use, for

maintenance, for periodic examination and for repair in language of the country in which the product is to be used.

!personal protective equipment must be withdrawn from use immediately when any doubt arise about its condition for safe use and not used again until confirmed in writing

by equipment manufacturer or his representative after carried out the detailed inspection.

!personal protective equipment must be withdrawn from use immediately and destroyed (or another procedures shall be introduced according detailed instruction from

equipment manual) when it have been used to arrest a fall.

PERIODIC INSPECTIONS

Safety harness must be inspected at least once every 12 months from

the date of first use. Periodic inspections must only be carried out by a

competent person who has the knowledge and training required for

personal protective equipment periodic inspections. Depending upon

the type and environment of work, inspections may be needed to be

carried out more frequently than once every 12 months.

MAXIMUM LIFESPAN OF THE EQUIPMENT

The maximum lifespan of the harness is 10 years from the date of

manufacture.

ATTENTION: The harness maximum lifetime depends on the intensity

of usage and the environment of usage. Using the harness in rough

environment, marine environment, contact with sharp edges, exposure

to extreme temperatures or aggressive substances, etc. can lead to the

withdrawal from use even after one use.

WITHDRAWAL FROM USE

The harness must be withdrawn from use immediately and destroyed

when it has been used to arrest a fall or it fails to pass inspection or

there are any doubt as to its reliability.

Every periodic

inspection must be recorded in the Identity Card of the equipment.

1.1 1.2 2.1

2.2

1.3

ATTACHING FALL ARRESTS SYSTEMS – EN361

Fall arrest system can be attached only to the fall arrest attachment point of full body harness EN 361 marked with capital letter A:

- directly to the back D-ring (1.1)

- to the front attachment loops. The loops marked with a half of letter must be linked together when attached to the fall arrest

system (1.2). It is strictly forbidden to attach a fall arrest system to a single loop with a half of letter A (1.3).

Harness is put on correctly if:

- All straps are correctly adjusted (neither too loose nor too tight).

- Dorsal attachment D-ring is correctly positioned at the shoulder blades.

- The ends of the all straps are secured with flexible loops.

NOTE: Before using the belt for the first time

the user should carry out a suspension test

in a safe place to ensure that the sit harness

has correct size, is properly adjusted and is of an

acceptable comfort level for the intended use.

It’s important to check the sit harness regularly

for any damage.

WARNING!

It is strictly forbidden to attach any fall arrest system to lateral buckle of the work positioning belt during work.

ATTACHING WORK POSITIONING/RESTRAINT SYSTEM (EN 358)

- waist belt should not be used if there is a foreseeable risk of the user becoming

suspended or being exposed to unintended tension by the waist belt

- when using a work positioning system, the user normally relies on the equipment for

support, therefore it is essential to consider the need of using a back-up, e.g. a fall arrest

system

- Work positioning or restraint system can be attached to lateral buckles of the work

positioning belt (3)

- Work positioning lanyard must be attached on a structural point located at the user's

waist or above and kept taut.

A/2 A/2

A/2

2.1

2.3