7

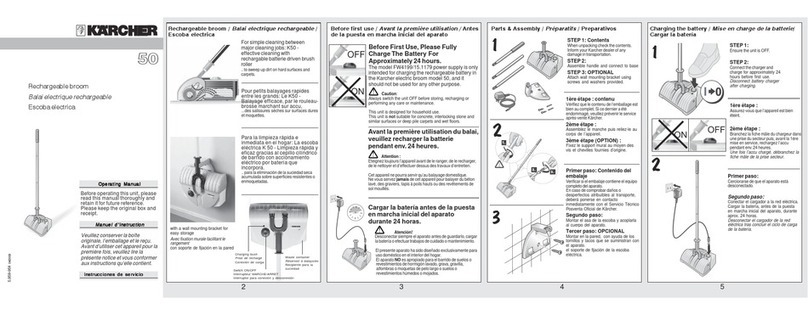

3. Getting started

3.4 Switching the cleaner ON

Donotswitchthecleaneronifthereisnowater

intheboiler,otherwiseitcouldoverheat.Asa

safetymeasure,thecleaner’sheaterswitches

off automatically and the low-water warning

lamp illuminates.Inordertobeabletousethe

cleaneragain,waitapprox.10minutesforitto

cool down and then fill the boiler with water

(see2.6“Fillingupwithwater”).

• Plug the cleaner into a mains socket. Switch

both the steam supply switch (A5) and the

heater switch (A4) to ON.

The two indicator lamps integrated into the

switches should illuminate. When the oran-

ge lamp for the heater (A7) goes out again,

the cleaner is ready for use.

Whentheapplianceisswitchedon,doNOT

place in a vertical position. To prevent the

appliance from overheating, a built-in safety

deviceisolatestheapplianceandallindicator

lights switch off. Place the appliance back in

its original horizontal position. The indicator

lights switch on again and you can continue

working.

• Switch off the heater before moving the cle-

aner.

• When you are ready to start work with the

cleaner, you must first release the locking

mechanism (child lock (C4)) on the steam

gun (C1), otherwise you will not be able to

operatethe steamswitch (C3).Slide thelok-

king mechanism forwards and you will then

be able to press the steam switch.

Note:

Slidethelockingmechanismtowardsthe

reartoengagethe childlockwheneveryou are

not using the steam gun.

• When you press the steam switch, steam is

discharged from the nozzle. Begin by poin-

ting the steam gun at a cloth until a steady

flow of steam comes out of the nozzle.

• The heater is repeatedly switched on while

you are using the cleaner, in order to main-

tain the pressure inside the boiler. At the

same time the orange indicator lamp (A7)

illuminates.

3.5 Regulating the volume of steam

• The amount of steam can be regulated ac-

cording to requirement by adjusting the

handwheel (C7) on the steam gun. When

the wheel is turned forwards, a large

amount of steam is discharged; when it is

turned towards the rear, a small amount of

steam is discharged.

Note:

Whenthehandwheelissetforminimum

steam,itispossiblethatsteamwillcontinueto

be discharged briefly after the steam switch

(C3) has been released, until the pressure in

thesteamhosehas dropped.Youcanaccele-

rate this process by briefly turning the hand-

wheel (C7) forwards.

3.6 Refilling with water

Note:

When the water in the boiler has been

used up, the red low-water warning lamp (A6)

will illuminate. The safety cap (A2) cannot be

opened while there is any pressure at all in the

boiler.

• Turn off the heater switch but leave the

steam supply switch on.

• Press the steam switch on the steam gun

and hold it pressed until steam is no longer

discharged from the nozzle. There will then

be no pressure inside the boiler.

• Unscrew the safety cap from the cleaner.

If the cleaner has been in continuous use for

a long time, the safety cap (A2) may be hot!

Caution: Never lift the cleaner by the handle

unless the safety cap is in place!

• Pour a maximum of 1.2 litres of tap water

into the boiler.

Iftheboilerisstillhot,thereisariskthatwater

will be squirted back while it is being poured

into the boiler and cause scalding.

• Firmly screw the safety cap back onto the

cleaner. Turn on the heater switch again.

When the heater indicator lamp goes out,

the cleaner is ready for use again.