IMPORTANT!!!

INSTALLATION AND OPERATION NOTES

1.

One of the wooden side blocks protecting the contents of the cardboard is at the same time

a mounting holes template - do not throw it out before the installation is finished.

2.

The cassette and the bottom bar of the screen are protected against damage by polyurethane foam.

Remove the foams protecting the bottom bar after mounting the screen.

3.

The screen should be installed in a location away from moisture and strong sunlight.

4.

A properly mounted screen must be absolutely levelled.

5.

Use a soft, moistened cloth for cleaning. Do not use active cleaners. Protect the screen from ingress of

water or other liquid inside. After cleaning, the screen should be carefully wiped to remove any residual

moisture.

6.

DIMENSIONAL TOLERANCE: Projection surface: ± 20mm; components ± 3mm

7. The screen / elevator cannot have connected more than one remote control at once.

8. One remote control (for ex. RC01 / RC02 / Trigger 12V / Trigger230V / IR Receiver / RS Receiver,

etc.) cannot be connected at once to more than one screen, elevator, roller-blind, etc. Such connection

can only be made by using the SG-2 group controller.

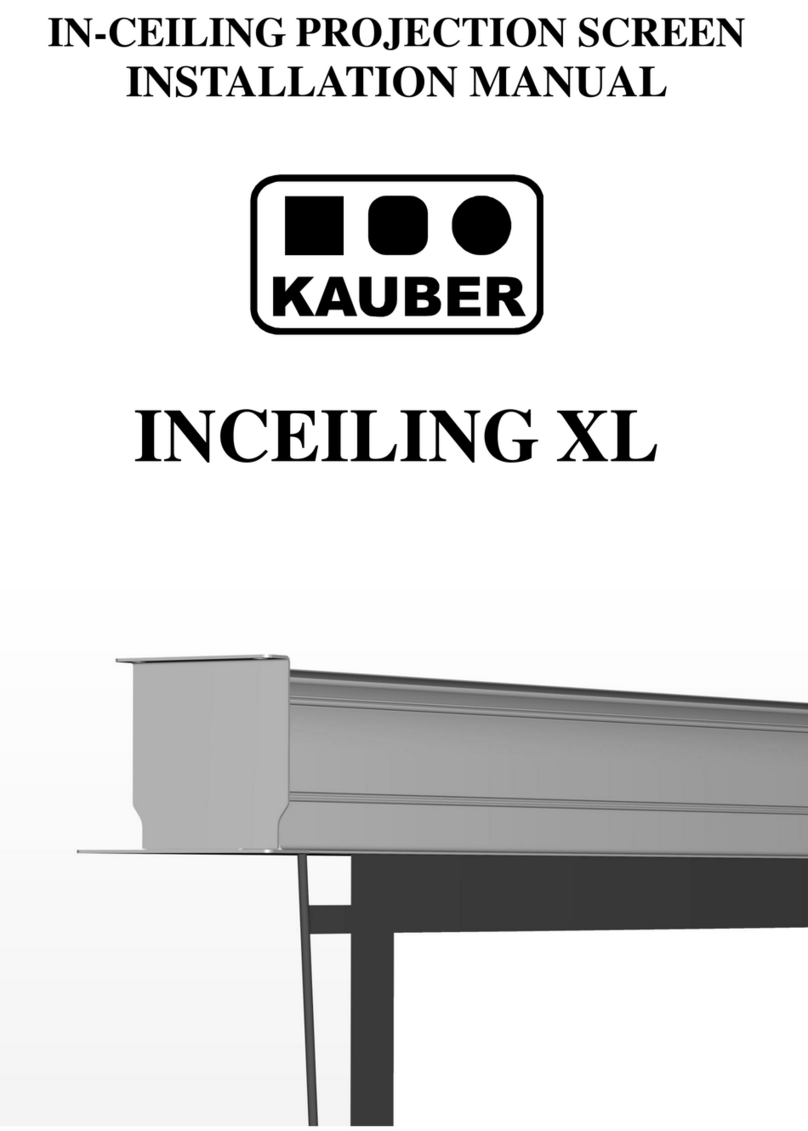

KAUBER InCeiling is a top-class electric projection screen, designed for installation in a suspended

ceiling. Its smartly designed aluminum housing has many installation aids. In the Tensioned version it is

additionally equipped with a special system to get an even more tense projection surface. The InCeiling

series was created for suspend ceilings in both conference rooms and home cinemas.