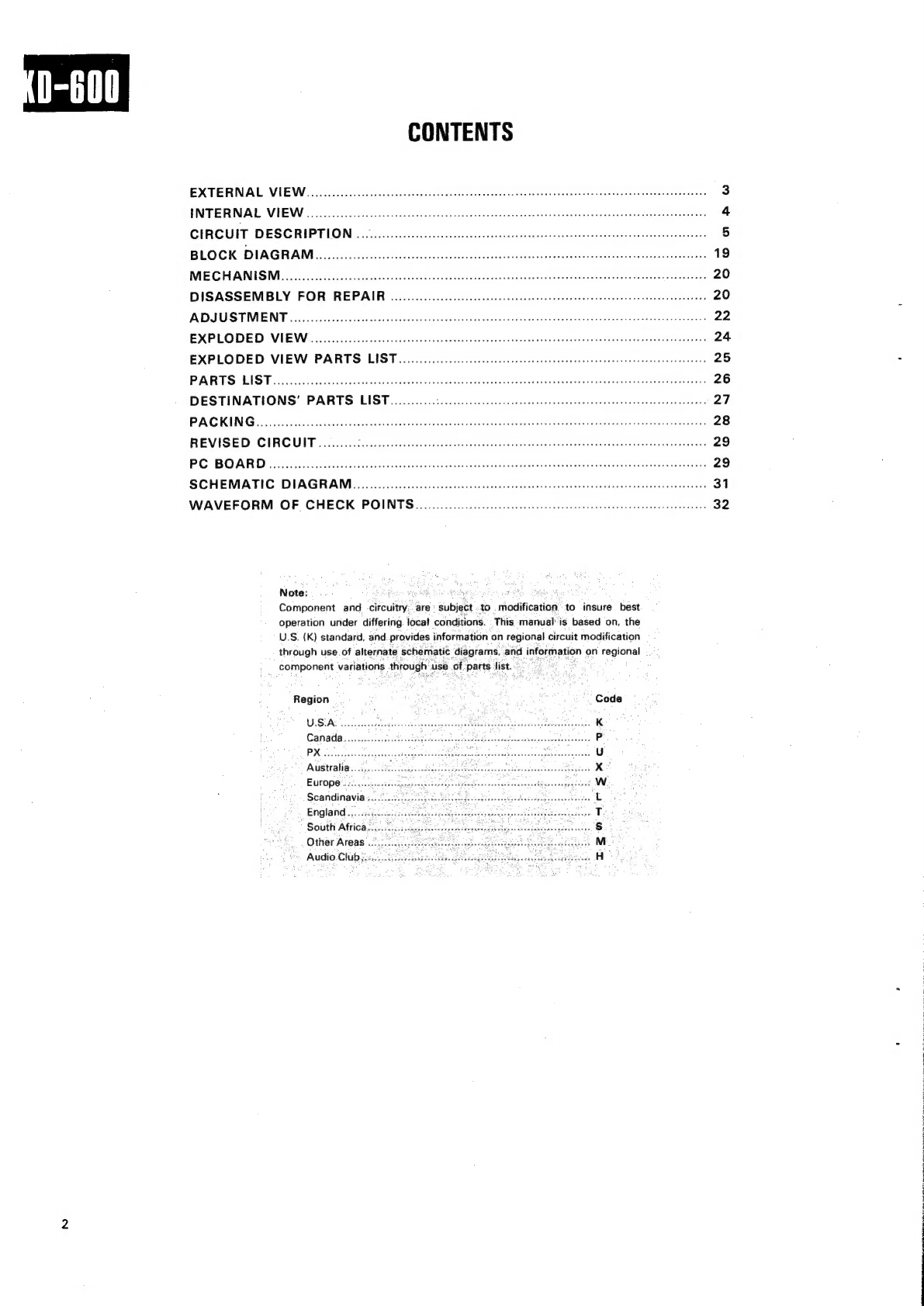

CONTENTS

EXTERNAL

VIEW.

0.cc

occ

decsscesesacs

Seca

ie

acetates

tetie

coodd

ds

Bia

des

hese

ea

yaa

daGaea

cue

meets

Behe

3

INTERNAL

VW

ete

cd

nce

dd

iennes

Sestetade

sehen

dand aces

bee

dented

es

cue

tabsaneoauvenwepadee

saath

4

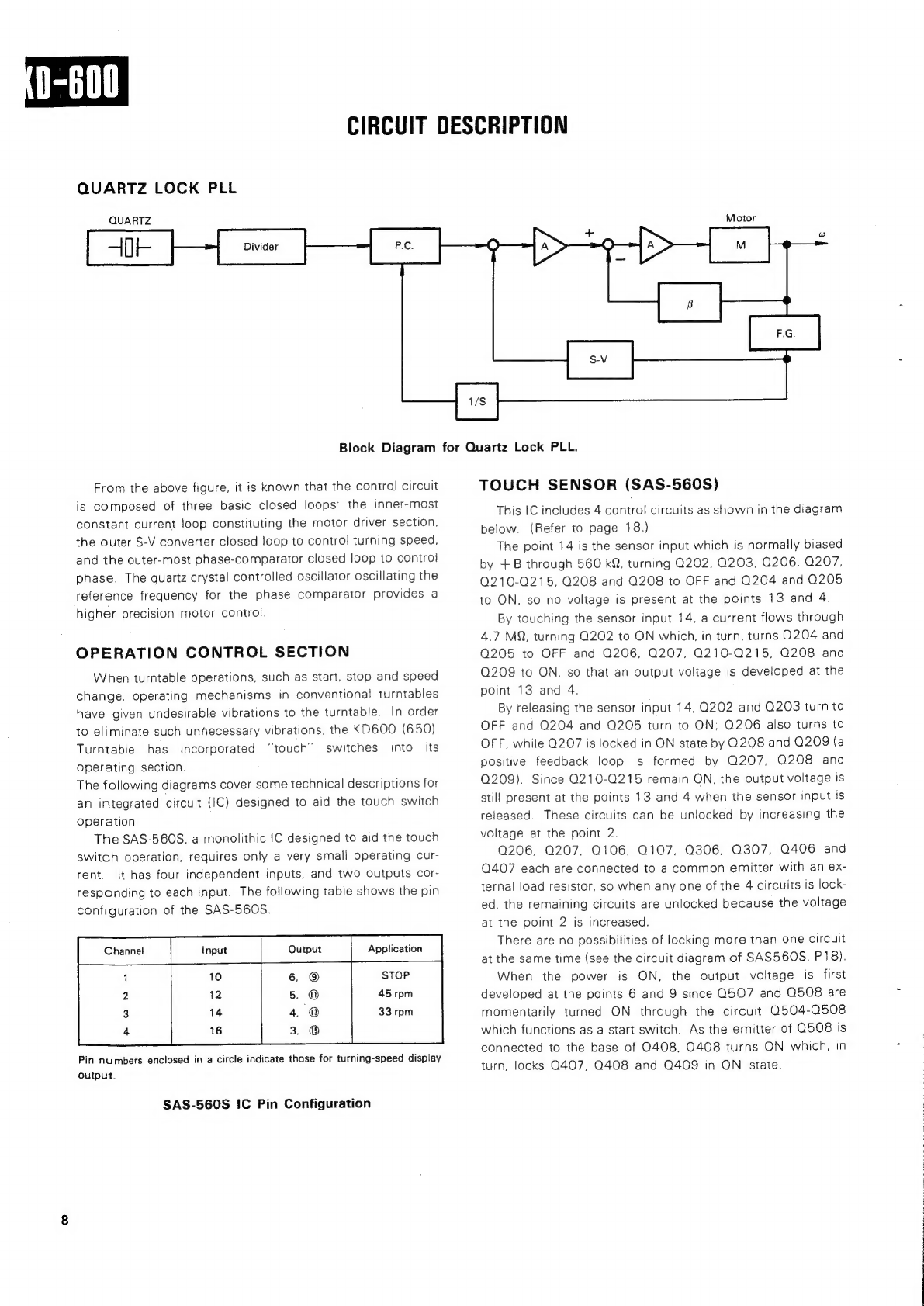

CIRCUIT

DESCRIPTION

ico

vsescssssesie

inna

disa

sees

nds

decciew

gene

Sane

Roce

acea

ie

eee

BLOCK

DIAGRAM

ME

GHANIUS

Wiiiiiiisscd

scacetcae

testes

thts

Seite

decd

scceseeuiskonn

veboeaeaovcs

ea

onaeh

oes tas

tude

aeaderdeedee

tet

DISASSEMBLY

FOR

REPAIR

.................:ccccceceeeee

nec

ne

etree

eee

bene

ee

rea

n

een

eee

eee

ant

E

nese

ees

ADIUSTIMEN

TT

oiscisiikscatssccned

cosnwciaacs

caias

daveiueee

rea

deeds

ciiaqwinos

coceh

thant

ped

ve

dace

dea

eredomernegened

EXPLODED:

VIEW

a

wskicisincicncg

ed

iadh

cides

ee

nstin corer eater

ccdote

aeves

ck.

adidas

sha

ahieseigue

paatekeereesieae’

EXPLODED

VIEW

PARTS

LIST

...........0...0.0c

cece

eter

e

tebe ener

entre

te

etree

renee

neen

ees

.

PARTS

(LIST

ic

iessctissensetiphetvieanade

sa

sseieatsa

saad

atatiaw

rata

cont

evederaienb

een

canebighs

dae

smianh

as

eve

eee

DESTINATIONS’

PARTS

LIST...........

Bag

Cpe

E

ey

dale

bg

WRAP

eR

SUR

LE

a

ot

ewan

TRG

PACKING

REVISED

CIR

CUUT

2iceisikcBiccastv

etnias

dead

coapcviesens

vorsaupcdewd

ebaie

ous

Neel

eee

seaesd

es

Decne

aes

PCABO

AR

Dies

tctck

cnt

teas

ba

bie

boesuta

daca

saaainsie

eee

merino

es

euictosatta

caitalese

wee

eens

wut

ohne

d

tits

sees,

cee

SCHEMATIC

DIAGRAM

boii

osscissssseacscop

vacuea

ae

ctegucaceten

tel

Secdss

nie

de

biaadabs

ay

vnvadae

Oarae

neg

ees

WAVEFORM

OF

CHECK

POINTS

Note:

fry

Component

and

circuitry:

‘are

subject

to

modification’

to

insure

best

operation

under

differing.

local

conditions.

This

manual

is

based

on,

the

U.S.

(K)

standard,

and.

provides

information

on

regional

circuit

modification

through

use

of

alternate

schematic

diagrams,

and

information

on

regional

component

variations

through

use

of

parts

list...”

s

Region

:

Code

WSIAS

reccastans

vet

inetevaseosuceseviasedeninaustnees

pitignse

Sastre

K

Canada....cccscciasesi

he

eghetih.

ceo

Gosat

ssslbed

ie

eeiasedseeseves

P

PX

rcdcsctes'sbveok

cues

Crate

clucus

ox

Soave

ranaees

wces

caiboass

Mitaner

eaten

oe

tet

eee

U

ANUS

tral,

sj

sacs

Sh

0s

oa ae

ae

eco

saaawi

tetceeddsad

Fieteedere

geen!

x

EWPODO

123g.

sein

ise

Sdapesecneatepohsecenenes

cot

patevcheoutacealSocevseqegecued

Ww

Scandinavia

secrecy

teh

cold

Mabvelecdetandbeccdscponsccoghesde'

L

England

.....i.0..

South

Africa...

Other

Areas

....

Audio.

Clubj.i.

Gis

specie