RFS-BA-e-1110

10

4 Basic Safety Precautions

4.1 Pay attention to the instructions in the Operation Manual

Carefully read this operation manual before setup and commissioning, even if you

are already familiar with KERN balances.

4.2 Personnel training

The appliance may only be operated and maintained by trained personnel.

5 Transportation & Storage

5.1 Testing upon acceptance

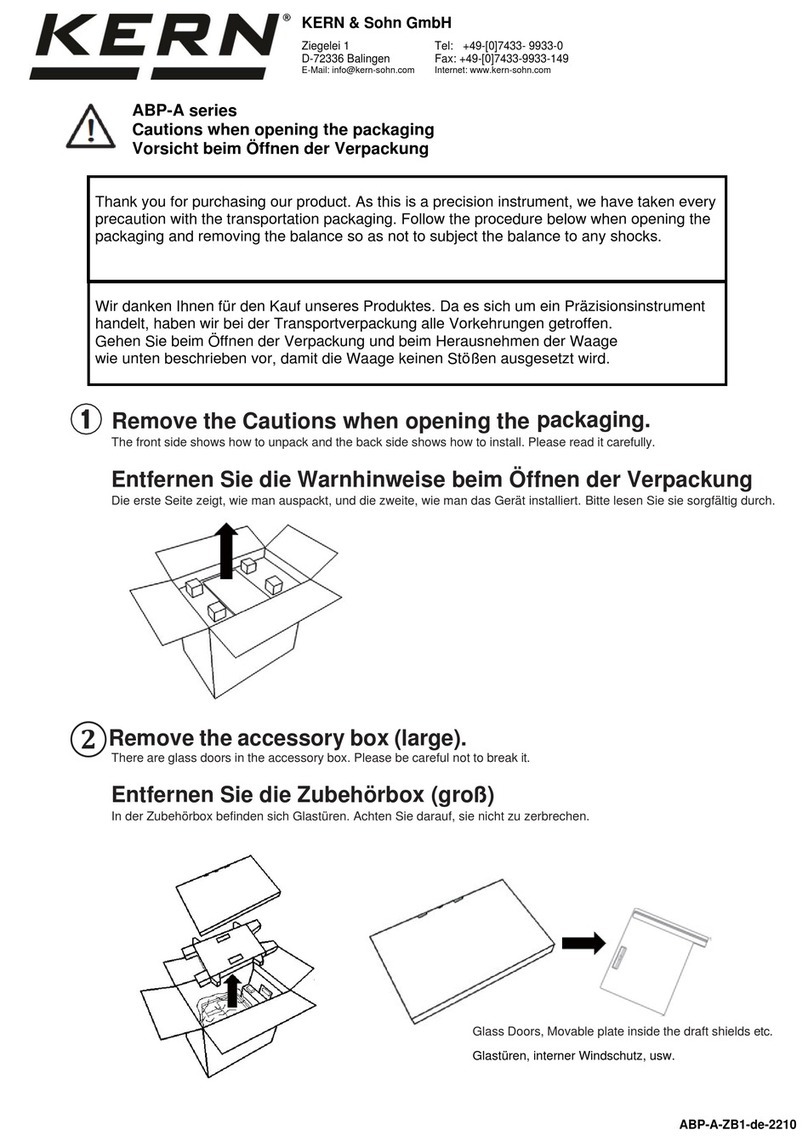

When receiving the appliance, please check packaging immediately, and the

appliance itself when unpacking for possible visible damage.

5.2 Packaging

Keep all parts of the original packaging in case you need to return the appliance.

Only use original packaging for returning. Before sending, disconnect all connected

cables and loose/movable parts. Attach possibly existing transport safeguards.

Secure all parts, e.g. weighing plate, power unit etc., to prevent slipping and damage.

6 Unpacking, Setup and Commissioning

6.1 Installation Site, Location of Use

The balances are designed in a way that reliable weighing results are achieved in

common conditions of use. You will work accurately and fast, if you select the right

location for your balance.

On the installation site observe the following:

•Place the balance on a firm, level surface;

•Avoid extreme heat as well as temperature fluctuation caused by installing

next to a radiator or in the direct sunlight;

•Protect the balance against direct draughts due to open windows and doors;

•Avoid jarring during weighing;

•Protect the balance against high humidity, vapours and dust;

•Do not expose the device to extreme dampness for longer periods of time.

Non-permitted condensation (condensation of air humidity on the appliance)

may occur if a cold appliance is taken to a considerably warmer environment.

In this case, acclimatize the disconnected appliance for ca. 2 hours at room

temperature.

•Avoid static charge of goods to be weighed or weighing container.

If electro-magnetic fields or static charge occur, or if the power supply is unstable

major deviations on the display (incorrect weighing results) are possible. In that case,

the location must be changed.