KIESELMANN GmbH Table of contents

6164_EN III

Table of contents

1 General informations ....................................................................................................................................................4

1.1 Informations for your safety ...............................................................................................................................................4

1.2 Marking of security instructions.........................................................................................................................................4

1.3 General designated use ......................................................................................................................................................4

1.4 Personnel .............................................................................................................................................................................4

1.5 Modifications, spare parts, accessories ............................................................................................................................5

1.6 General instructions ............................................................................................................................................................5

2 Safety instructions........................................................................................................................................................6

2.1 Intended use ........................................................................................................................................................................6

2.2 General notes.......................................................................................................................................................................6

2.3 General safety instructions.................................................................................................................................................6

3 Delivery, transport and storage .....................................................................................................................................7

3.1 Delivery.................................................................................................................................................................................7

3.2 Transport..............................................................................................................................................................................7

3.3 Storage.................................................................................................................................................................................7

4 Function and operation .................................................................................................................................................8

4.1 Description of function........................................................................................................................................................8

4.2 Commissioning, service and maintenance........................................................................................................................8

4.2.1 Commissioning...................................................................................................................................................... 8

4.2.2 General welding guidelines ................................................................................................................................... 8

4.2.3 ATEX - Guidelines .................................................................................................................................................. 8

4.2.4 Service.................................................................................................................................................................... 8

4.2.5 Cleaning ................................................................................................................................................................. 9

4.3 Pressure setting...................................................................................................................................................................9

5 Technical data ............................................................................................................................................................10

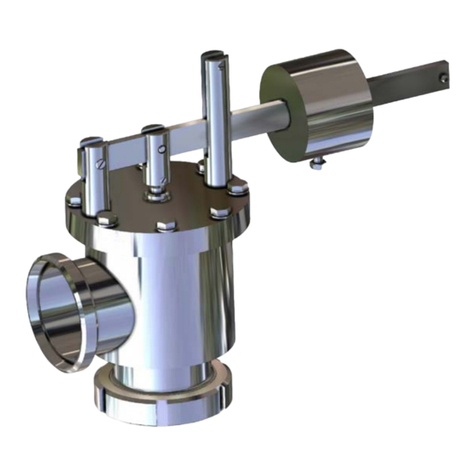

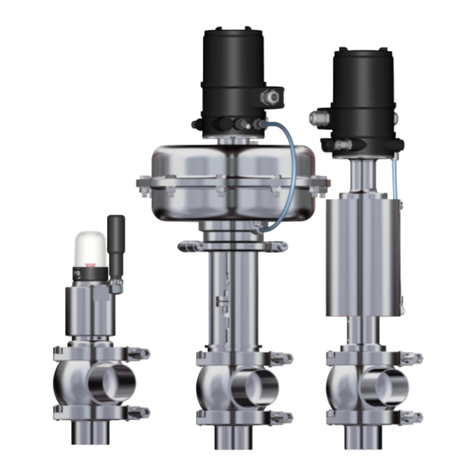

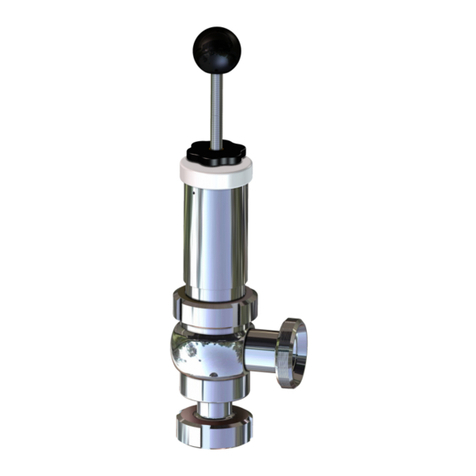

5.1 Vacuum valve ....................................................................................................................................................................10

5.2 Identification......................................................................................................................................................................10

5.3 Pneumatic actuator...........................................................................................................................................................11

5.4 heating system ..................................................................................................................................................................11

6 Disassembly and assembly .........................................................................................................................................12

6.1 Disassembly.......................................................................................................................................................................12

6.2 Assembly ...........................................................................................................................................................................13

7 Drawings and dimensions ...........................................................................................................................................14

7.1 Drawings ............................................................................................................................................................................14

7.2 Dimensions ........................................................................................................................................................................16

8 Wearing parts .............................................................................................................................................................18

9 Characteristic curves ..................................................................................................................................................19

9.1 Performance chart ............................................................................................................................................................19

10 Appendix ....................................................................................................................................................................21

10.1 Declaration of incorporation.............................................................................................................................................21

www.sks-online.com

www.sks-webshop.com