11.2. Link the measurement to a customer.................................................................................................................... 26

11.3. Print the measurement on the ticket...................................................................................................................... 26

12. Perform a measurement of ambient O2..................................................................................................................... 27

12.1. Perform the measurement.................................................................................................................................... 27

12.2. Link the measurement to a customer....................................................................................................................27

12.3. Print the measurement on the ticket...................................................................................................................... 27

13. Perform a measurement of max O............................................................................................................................. 28

13.1. Perform the measurement.................................................................................................................................... 28

13.2. Link the measurement to a customer....................................................................................................................28

13.3. Print the measurement on the ticket...................................................................................................................... 28

14. Perform some temperature measurements...................................................................................................................29

14.1. Perform a measurement of ambient temperature.................................................................................................. 29

14.2. Perform a measurement of flue gas temperature.................................................................................................. 29

14.3. Perform an ambient temperature measurement with the internal sensor..............................................................29

14.4. Perform a dewpoint temperature measurement....................................................................................................29

14.5. Link the measurements to a customer.................................................................................................................. 29

14.6. Print the measurement on the ticket...................................................................................................................... 29

15. Perform a measurement of opacity............................................................................................................................... 30

15.1. Perform the measurement.................................................................................................................................... 30

15.2. Enter the indexes in the analyser..........................................................................................................................30

15.3. Link the index to a customer................................................................................................................................. 30

15.4. Print the index on the ticket................................................................................................................................... 30

16. Perform a measurement of ionisation current............................................................................................................... 31

16.1. Perform the measurement.................................................................................................................................... 31

16.2. Link the measurement to a customer....................................................................................................................31

16.3. Print the measurement on the ticket...................................................................................................................... 31

17. Perform a H4 measurement....................................................................................................................................... 32

17.1. Perform the measurement with the probe............................................................................................................. 32

17.2. Perform the measurement with the sensor...........................................................................................................32

17.3. Link the measurement to a customer....................................................................................................................32

17.4. Print the measurement on the ticket...................................................................................................................... 32

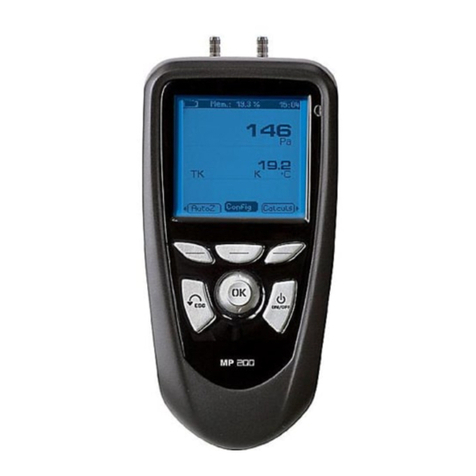

18. Perform a measurement with a Pitot tube..................................................................................................................... 33

18.1. Link the measurement to a customer....................................................................................................................33

18.2. Print the measurement on the ticket...................................................................................................................... 33

19. To get to information about the analyser....................................................................................................................... 34

20. Maintenance of the analyser......................................................................................................................................... 35

20.1. Life-time of the sensors......................................................................................................................................... 35

20.2. Replace the sensors............................................................................................................................................. 35

20.3. Replace the paper roll of the printer...................................................................................................................... 36

20.4. Replace the battery............................................................................................................................................... 37

20.5. Replace the filter................................................................................................................................................... 37

21. alculations of the different parameters........................................................................................................................ 38

21.1. O and NO conversions....................................................................................................................................... 38

21.2. alculation of the level in NOx.............................................................................................................................. 38

21.3. alculation of flue gas velocity.............................................................................................................................. 38

LIGAZ SOFTWARE

1. Introduction..................................................................................................................................................................... 40

2. Software installation........................................................................................................................................................ 40

2.1. Recommended minimum configuration...................................................................................................................40

2.2. Installation............................................................................................................................................................... 40

3. Start with the software..................................................................................................................................................... 41

3.1. Meaning and functions of the menus bar (1)........................................................................................................... 41

3.2. Meaning and functions of tool bar buttons (2).........................................................................................................42

4. Unload inspections.......................................................................................................................................................... 43

5. Use the different databases............................................................................................................................................ 44

5.1. Use the customer database.................................................................................................................................... 44

5.2. Use the boilers database........................................................................................................................................ 45

5.3. Total database......................................................................................................................................................... 46

5.4. Set the database..................................................................................................................................................... 46

5.5. Save while using..................................................................................................................................................... 46

5.6. Import a database................................................................................................................................................... 46

6. Set the analyser.............................................................................................................................................................. 47

6.1. hange the combustibles........................................................................................................................................ 47

6.2. hange the references............................................................................................................................................ 47

6.3. Manage the operators............................................................................................................................................. 47

6.4. hange date and time............................................................................................................................................. 47

6.5. Sensors state.......................................................................................................................................................... 47