5

1. INTRODUCTION

Congratulations. You have acquired an excellent equip-

ment for the treatment of water at home.

This equipment will allow you to improve the qualities

of water.

2. WHAT IS OSMOSIS?

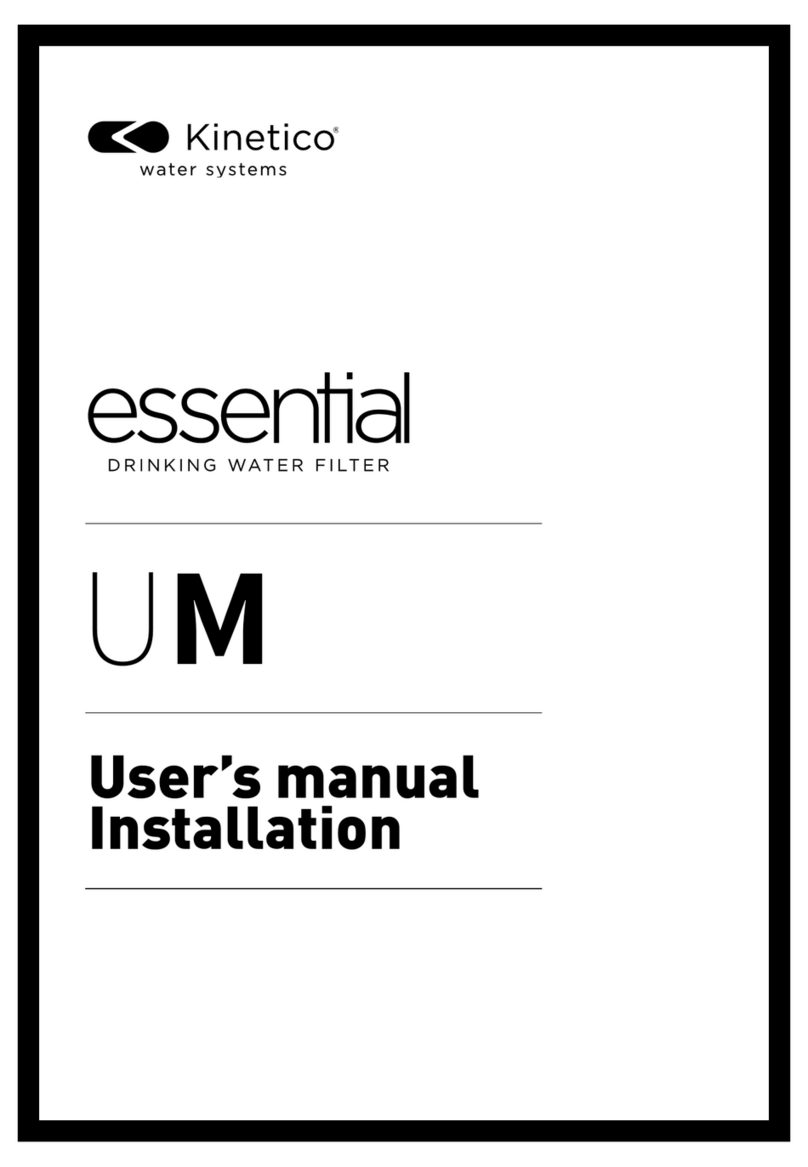

Natural or direct osmosis is more common in nature,

since semi-permeable membranes are part of the vast

majority of organisms (for example, plant roots, the or-

gans of our own body, cellular membranes, etc.).

When two solutions of different concentrations of salt

are separated by a semi-permeable membrane, natura-

lly, a flux of water is produced from the solution with a

lower concentration toward that with higher concen-

tration. This flux will continue until the concentrations

in both sides of the membrane are equal.

When it comes to inverting this process and achieving a

flux of water with a lower concentration of salt starting

from one with a higher concentration, there needs to be

enough pressure from the water with high concentration

over the membrane to overcome the natural tendency

and flux of the system. This process is what we call re-

verse osmosis. Currently, reverse osmosis is one of the

best methods available for improving the characteristics

of water through a physical system (without using che-

mical products).

The water that is to be purified puts pressure on the se-

mi-permeable membrane so that some of the water is

able to pass through the pores of the membrane (osmo-

sed water) while the rest of the water (rejected or with a

high concentration of salt) is diverted towards the drain.

3. PRIOR WARNINGS

ATTENTION: Please read carefully the warnings

described in the corresponding Technical Manual.

ATTENTION: This equipment does not PRODUCE

POTABLE water. If the water to be treated comes

from a public source (and therefore conforms to

all applicable laws), this equipment will substantially

improve the quality of the water.

The water treatment equipment requires regular main-

tenance that needs to be carried out by qualified te-

chnical personnel in order to guarantee the quality of

water produced and provided.

3.1. OPERATION OF THE EQUIPMENT

• If you are going to be absent for more than one week,

close the equipment’s water inlet valve, empty it and

disconnect it from the power supply (PUMP model).

When you return, connect the power supply to the

equipment, open the inlet valve and the tap. Let the

water flow for 5 minutes before consuming it.

ATTENTION: If the equipment has not worked or

has not produced water for a prolonged period of

time (more than one month), get in touch with the

distributor in order to set up its appropriate sanitiza-

tion and maintenance.

• Extract full jugs and bottles and avoid extracting oc-

casional glasses to improve the performance of the

equipment.

ATTENTION: You must pay particular attention to

the cleanliness and hygiene of the osmosis tap on

a regular basis and especially when carrying out

the periodic minatenance and sanitation procedures.

To do so, use sanitizing spray and single use kitchen

paper. Under no circumstances should you use towels

that you use to dry your hands or kitchen towels.

3.2. RECOMMENDATIONS FOR THE PROPER USE OF OS-

MOSIS WATER

• If you wish to supply with osmosis water any consump-

tion point (such as a refrigerator with ice cube dispen-

ser, another rap, etc.), the channelling should not be

done with a metalic tube, since this would give a bad

flavour to the water. Always use plastic tubes.

ATTENTION: The water supplied by the osmosis

equipment is of LOW MINERALIZATION. The mi-

neral salts that the human body needs are largely

provided by food, especially by dairy products, and to

a lower extent, by drinkable water.

• We recommend that you use aluminium utensils to

cook with osmosis water.

Osmosis Membrane

Membrane

Contamination Water Inlet

Bacteria Pressure over the membrane

Chemical Compounds Rejection Flow

Mineral Salts Membrane

Water Purified water flux

Purified Water

Inlet Pressure

Rejection: Water with re-

tained elements and salts