forward could cause the tractor to tip over

backward. Stay off hills and slopes too steep for

safe operation.

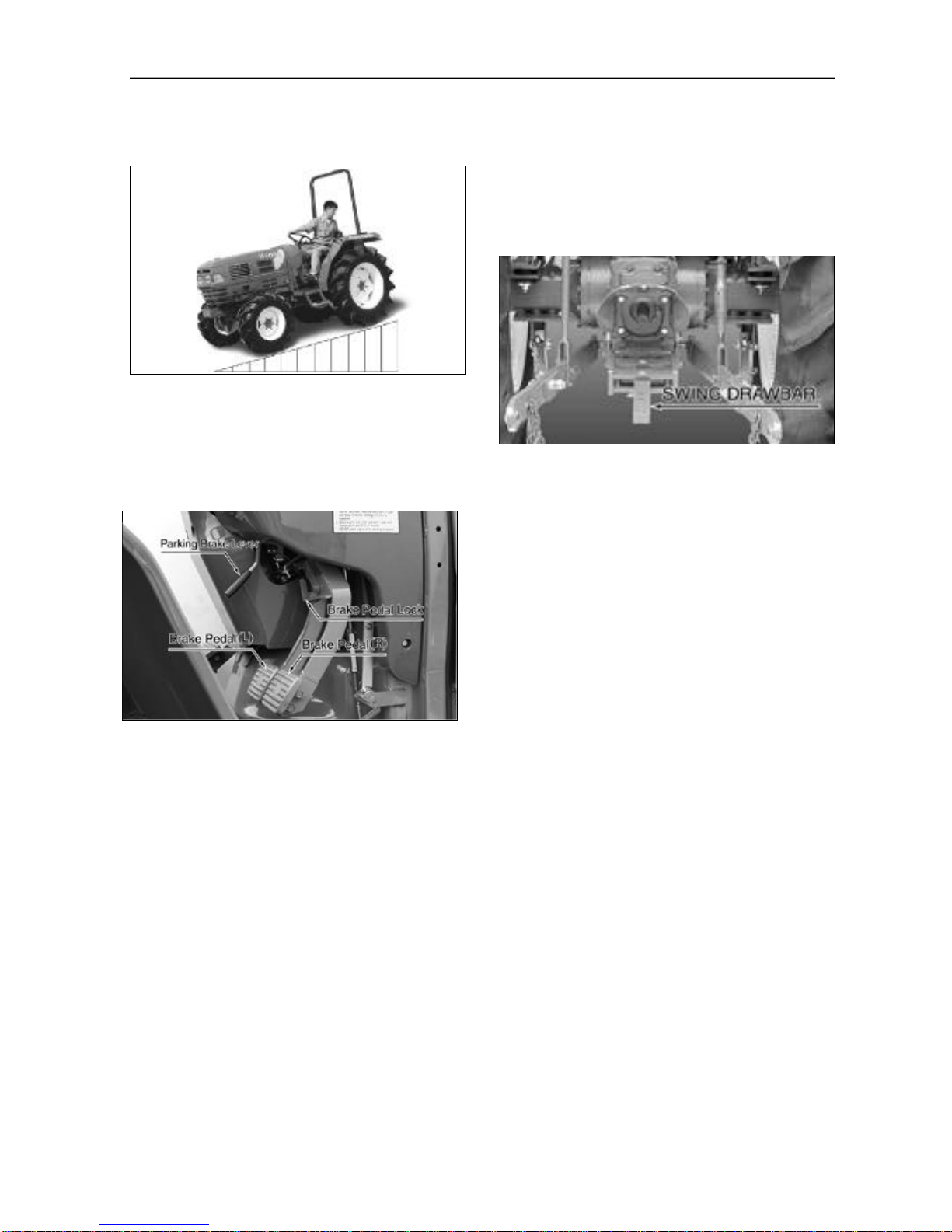

13. Lock the brake pedals together when travelling

at road speeds. Brake both wheels simul-

taneously when making an emergency stop.

Uneven braking at road speeds could cause

the tractor to roll over.

OPERATING THE TRACTOR

1. Apply the parking brake, place the lift control

lever in the down position and the P.T.O. control

switch and the transmission lever in neutral

before starting the tractor.

2. Avoid accidental contact with the gear shift levers

while the engine is running. Unexpected tractor

movement can result from such contact.

3. Shut off the engine and P.T.O. and apply the

parking brake before getting off the tractor.

4. Do not park the tractor on a steep incline.

5. Do not operate the tractor engine in an enclosed

building without adequate ventilation. Exhaust

fumes can cause death.

6. Tighten all connections before starting the

engine or pressurizing lines.

7. Pull only from the pick-up hitch, swinging draw-

bar or the lower link draw-bar in the lowered

position. Use only a draw-bar pin that locks in

place. Pulling from the tractor rear axle or any

point above the axle may cause the tractor to tip

over.

8. If the front end of the tractor tends to rise when

heavy implements are attached to the three-

point hitch, install front end weight. Do not

operate the tractor with a front end light.

9. Do not leave equipment in the raised position

when the tractor is stopped or unattended.

10. When installing or using an implement or other

attachment with the tractor, be sure to read the

“ Specifications of Implement Limitations”.

11. Know your equipment and its limitations.

12. When using an implement, be sure to install the

proper ballast weight on the tractor.

13. Ensure any attached equipment or accessories

are correctly installed, and approved for use

with the tractor. Do not overload the tractor and

are operated and maintained in accordance

with the instructions issued by the equipment or

accessory manufacturer.

14. Remember that your tractor, if abused, can be

dangerous and become a hazard both to the

operator and to bystanders. Do not overload or

operate with attached equipment which is

unsafe, not designed for the particular task or is

poorly maintained.

Refer to “Specifications of Implement

Limitations” recommended by KIOTI Dealer,

which outlines the maximum loads for safe

tractor operation.