- 4 -

PRE-DELIVERY SERVICE

CHECK AND ADJUST AS REQUIRED

INOPERATIVE SERVICE CHECKS

1. Tire pressure and condition.................................

2. Lift-rod leveling crank for proper operation.......

3. Radiator coolant level and specific gravity........

(1.071-1.083 at 16 °C (60°F))

4. Poly V belt.................................................................

5. Engine oil level .......................................................

6. Transmission /rear axle oil ..................................

7. Front axle differential oil level ..............................

8. Front axle oil level ..................................................

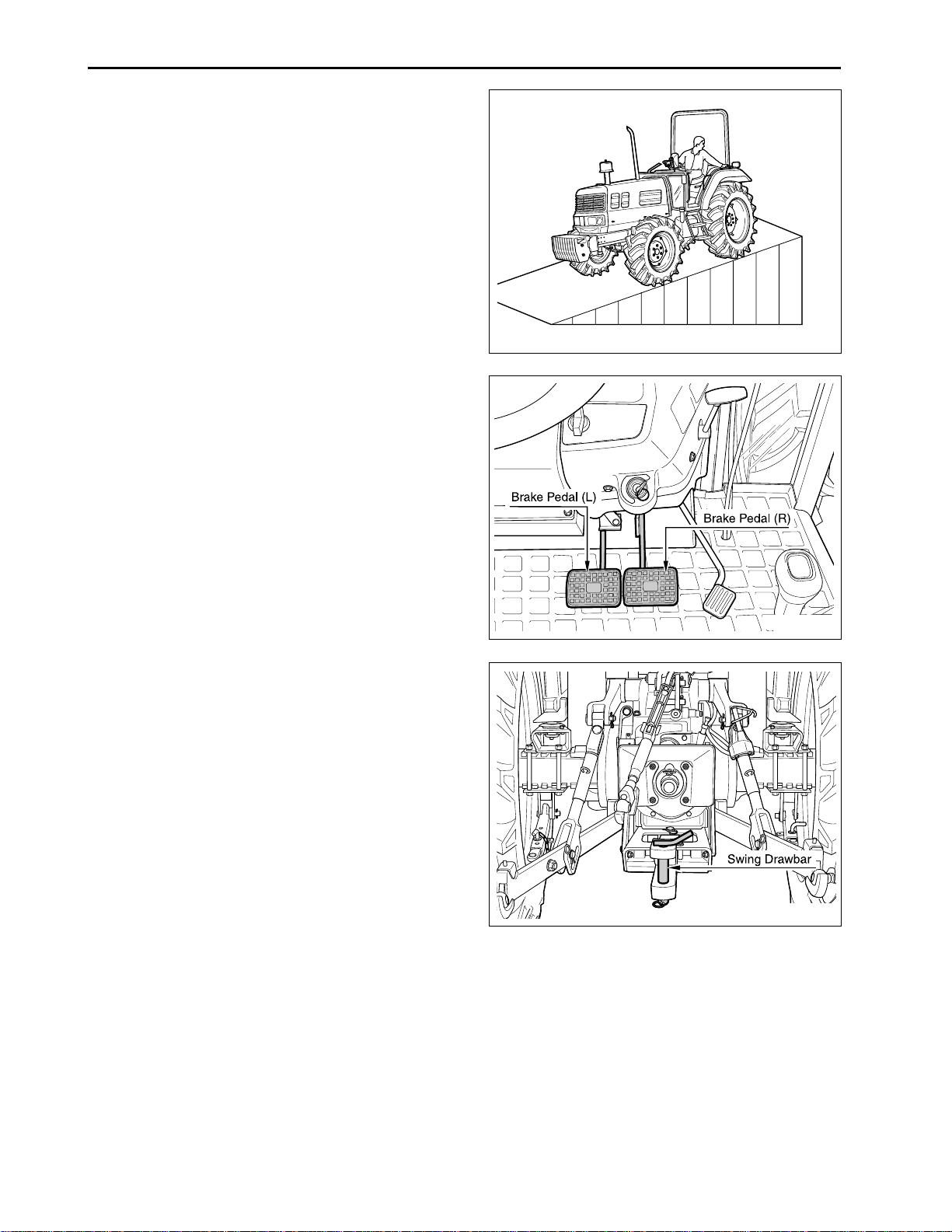

9. Brake adjustment and pedal equalization.........

10. Handbrake adjustment..........................................

11. Upper link, draw-bar and pin in position ...........

12. Wheel-to-rim clamp bolts and lock nuts for

tightness ..................................................................

13. Wheel disc-to-hub nuts for tightness .................

14. Front end weight clamp bolts for tightness.......

15. Front axle support bolts for tightness ................

16. Fuel level..................................................................

17. Sheet metal and paint condition..........................

18. Drain diesel fuel filter and water separator ......

19. Lubricate all grease fittings .................................

20. Air cleaner element and hose connections ......

21. Seat mounting and adjustment ...........................

22. All electrical cables, terminals and wires .........

SAFETY ITEMS CHECKS

1. Safety decals installed ..........................................

2. Neutral start switches operative..........................

3. Parking brake operation........................................

4. Flashing lights/tail lights operation

5. Owner’s Manual supplied..................................

6. PTO guard installed ............................................

7. SMV emblem installed(where applicable) .....

OPERATIVE SERVICE CHECKS

All operative checks are to be performed with the trac-

tor at normal operating temperature.

1. Lights and instruments for proper

operation...............................................................

2. Fluid and oil leaks...............................................

3. Maximum no-load speed and idle speed

adjustments and fuel shut-off...........................

4. PTO operation ......................................................

5. Hydraulic System:

• Select levers for Draft and Position Control

operation............................................................

• Fow control operation .....................................

• Draft Control for tension and compression

loads...................................................................

• Auxiliary Services Control and remoter

control valves (If installed).............................

PERFORMANCE SERVICE CHECKS:

1. Engine operation including throttle and

governor operation..............................................

2. Transmission, including....................................

3. Steering control ...................................................

4. Differential lock engagement and

disengagement....................................................

5. Brake action..........................................................

6. All optional equipment and accessories........

Tractor Model No. Tractor Model No.