OWNERS M NU L

Contents

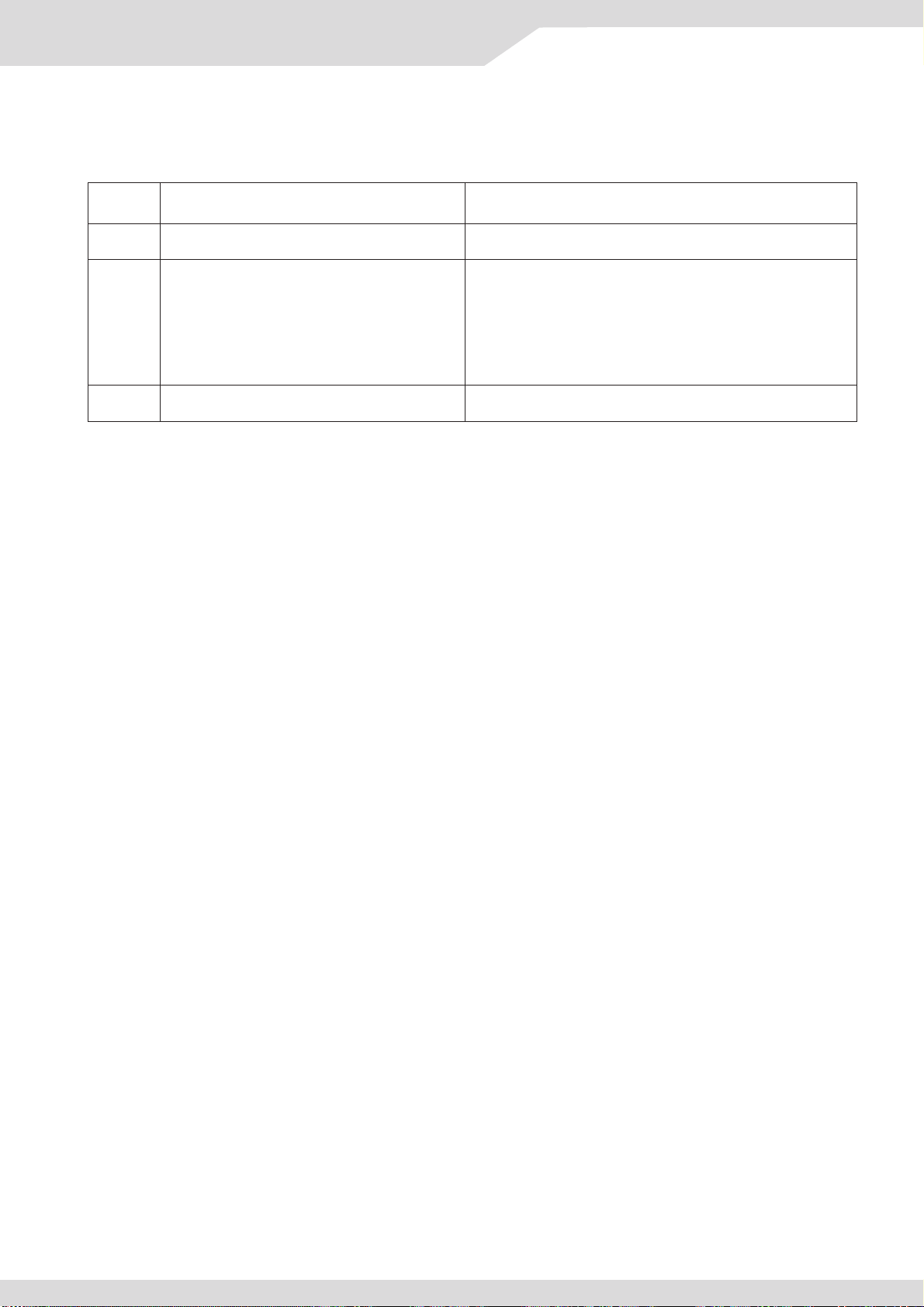

Sr. No. Description Page No.

1 MEGA T Warranty Period and Warranty Policy Guide Lines 1

1.1 Warranty Period 1

1

2 2

3 4-5

4

1.2 Warranty Policy Guide Lines

Warranty Registration Card / Sale Inti ation

Card Technical specifications—Mega T12LW - S

Safety Precautions and DOS & DON’TS

6

4.1 Safety Precautions of MEGA T 6

4.2 DOs 6-7

4.3 DON’TS 8

4.4 Recognize Decal Infor ation 9-10

5 Equip ent fa iliarization & Locations View 11

5.1 Equip ent View 11

5.2 Engine & Chassis Nu ber plate 12

6 Controls fa iliarisation & Operating Instructions 13

6.1 Accelerator (Throttle) Control lever 13

6.2 Clutch & Parking Brake Control 14

6.3.1 Clutch Engage & Disengage Lever & Parking Brake Lever 15

6.3.2 Parking Brake position 15

6.4 Steering Control 15

6.5 Gear Shifting 16

6.5.1 Main Gear Shifter Lever 16

6.5.2 High Low Range Selection Lever 16

6.5.3 Rototiller Speed Selection Gears 16

6.5.4 Side Power take off option (PTO) 17

6.5.5 Diesel and Water filling Locations with caps 17

6.5.6 Side flap for rotary tiller 18

6.5.7 Air cleaner Asse bly 18

6.5.8 Front Stand 19

7 Engine Starting Process 19

7.1 Engine Off & On Position 20

8 MEGA T adjust ents and Settings 20

8.1 V – Belt Tension Adjust ents 20-21

8.2 Clutch Adjust ent and Setting 21

8.3 Main Clutch and Brake Pull Rod Adjust ents 22

8.3.1 Clutch Pull rod adjust ent 22

8.3.2 Parking Brake adjust ent 22

8.4 Steering Adjust ent 23

8.5 Throttle Control Syste adjust ent 24

8.6 Wheel Track Width Changing Procedures 25

8.7 Trans ission Chain Adjust ent 26

26

8.7.1 Main trans ission chain

8.7.2 Rototiller Trans ission Chain Adjust ent

26

8.7.4 Rototiller Shaft Speed Changing Procedure 27

8.8 Tiller Shaft blade ounting sequence and blade types 27

8.8.1 Blade ounting sequence on tiller shaft 28