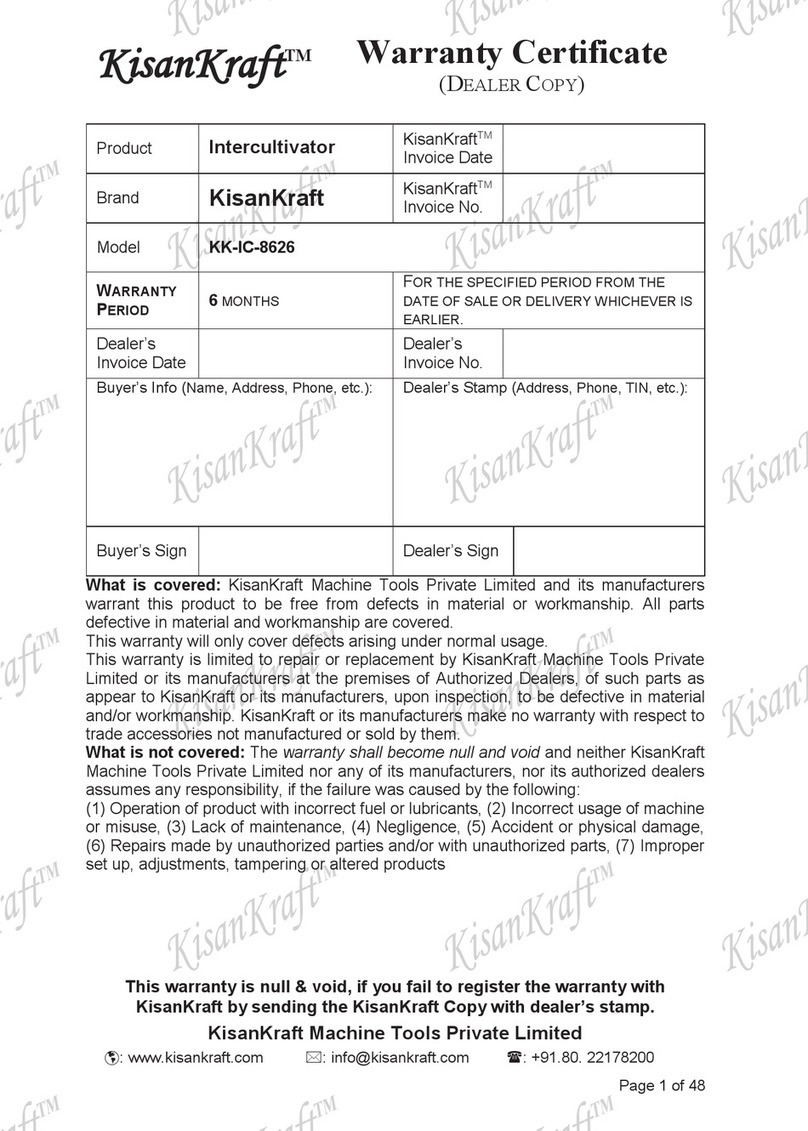

This warranty is null & void, if you fail to register the warranty with

KisanKraft by sending the KisanKraft Copy with dealer’s stamp.

KisanKraft Machine Tools Private Limited

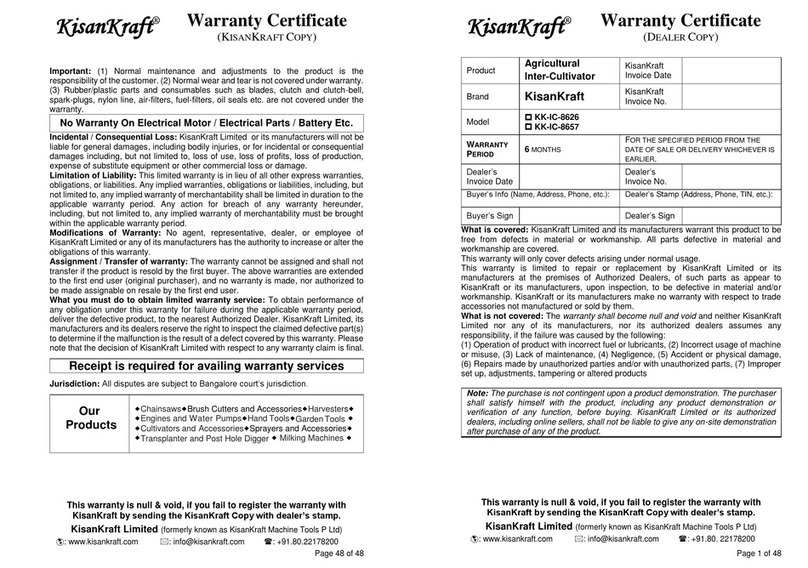

Incidental / Consequential Loss: KisanKraft Limited or its manufacturers will not be

liable for general damages, including bodily injuries, or for incidental or consequential

damages including, but not limited to, loss of use, loss of profits, loss of production,

expense of substitute equipment or other commercial loss or damage.

Limitation of Liability: This limited warranty is in lieu of all other express warranties,

obligations, or liabilities. Any implied warranties, obligations or liabilities, including, but

not limited to, any implied warranty of merchantability shall be limited in duration to the

applicable warranty period. Any action for breach of any warranties hereunder,

including, but not limited to, any implied warranty of merchantability must be brought

within the applicable warranty period.

Modifications of Warranty: No agent, representative, dealer, or employee of KisanKraft

Limited or any of its manufacturers has the authority to increase or alter the obligations

of this warranty.

Assignment / Transfer of warranty: The warranty cannot be assigned and shall not

transfer if the product is resold by the first buyer. The above warranties are extended to

the first end user (original purchaser), and no warranty is made, nor authorized to be

made assignable on resale by the first end user.

What you must do to obtain limited warranty service: To obtain performance of any

obligation under this warranty forfailureduring the applicable warranty period, you must

deliver the defective product, to the nearest Authorized Dealer, along with proof-of-

purchase (invoice/receipt). KisanKraft Limited, its manufacturers and its dealers reserve

the right to inspect the claimed defective part(s) to determine if the malfunction is the

result of a defect covered by this warranty. Please note that the decision of KisanKraft

Limited with respect to any warranty claim is final.

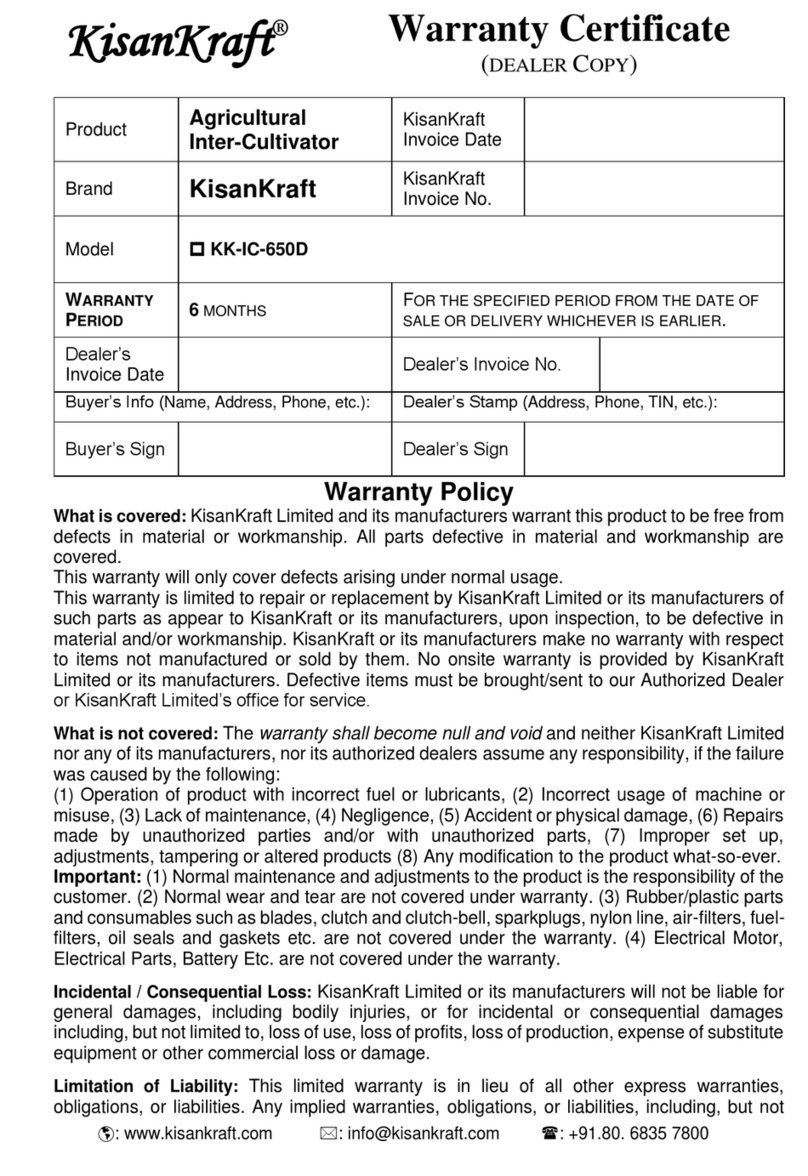

After-sales Service (Including Warranty): KisanKraft Limited does not sell directly to

consumers. All sales or supplies are made through Authorized Dealers. It is the

responsibility of the Authorized Dealer to provide all after-sales service to consumers.

Any warranty claim should be raised by dealer to KisanKraft Limited as per warranty

policy.

Jurisdiction: All disputes are subject to Bangalore court’s jurisdiction.

Notes:

➢This purchase is not contingent upon a product demonstration. The purchaser shall

satisfy himself with the product, including any product demonstration or verification

of any function, before buying. KisanKraft Limited or its authorized dealers,

including online sellers, shall not be liable to give any on-site demonstration after

purchase of any of the product.

➢Any product once used will not be taken back by KisanKraft Limited.

➢Warranty and After Sale Services (including but not limited to installation,

Demonstration, Repair, Routine Maintenance etc.), should be done through the

Authorized Dealer selling this product.

➢Dealers should have their own technician to provide After Sales Services to their

Customers. KisanKraft Limited provides free training to Authorized Dealer’s

technicians at KisanKraft Limited’s head office, on request from Authorized Dealer.