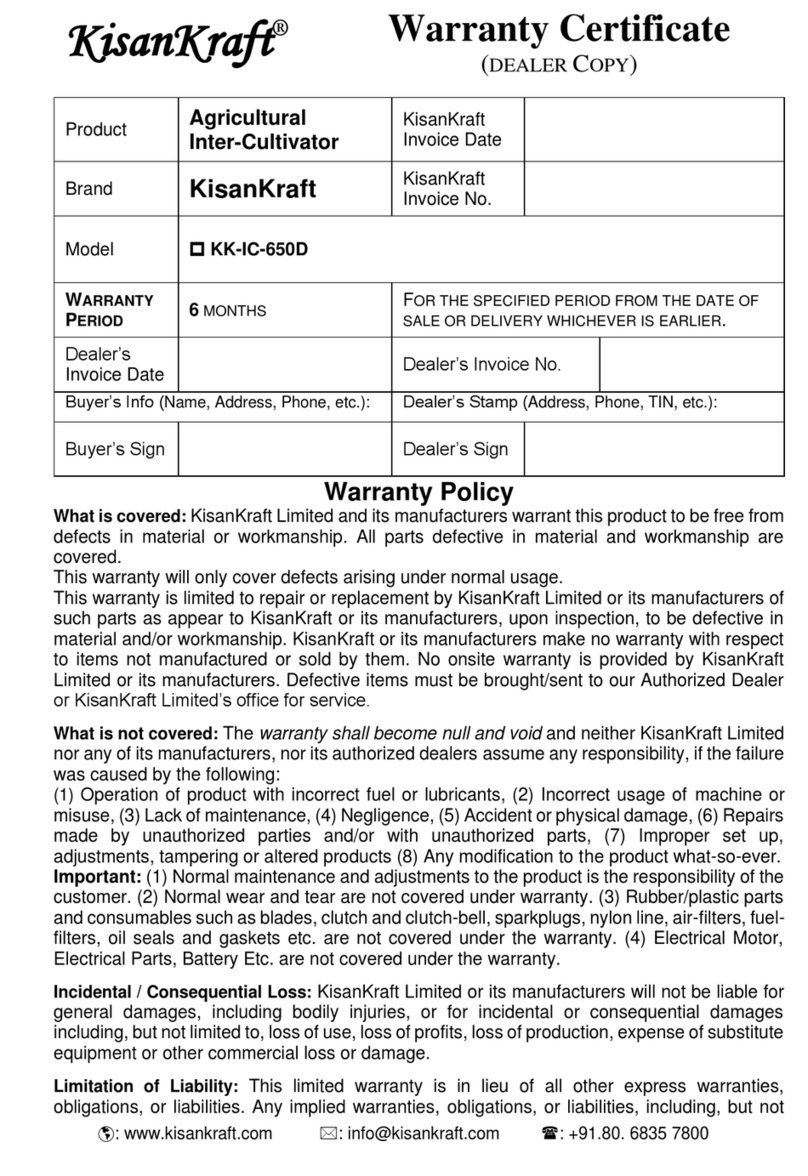

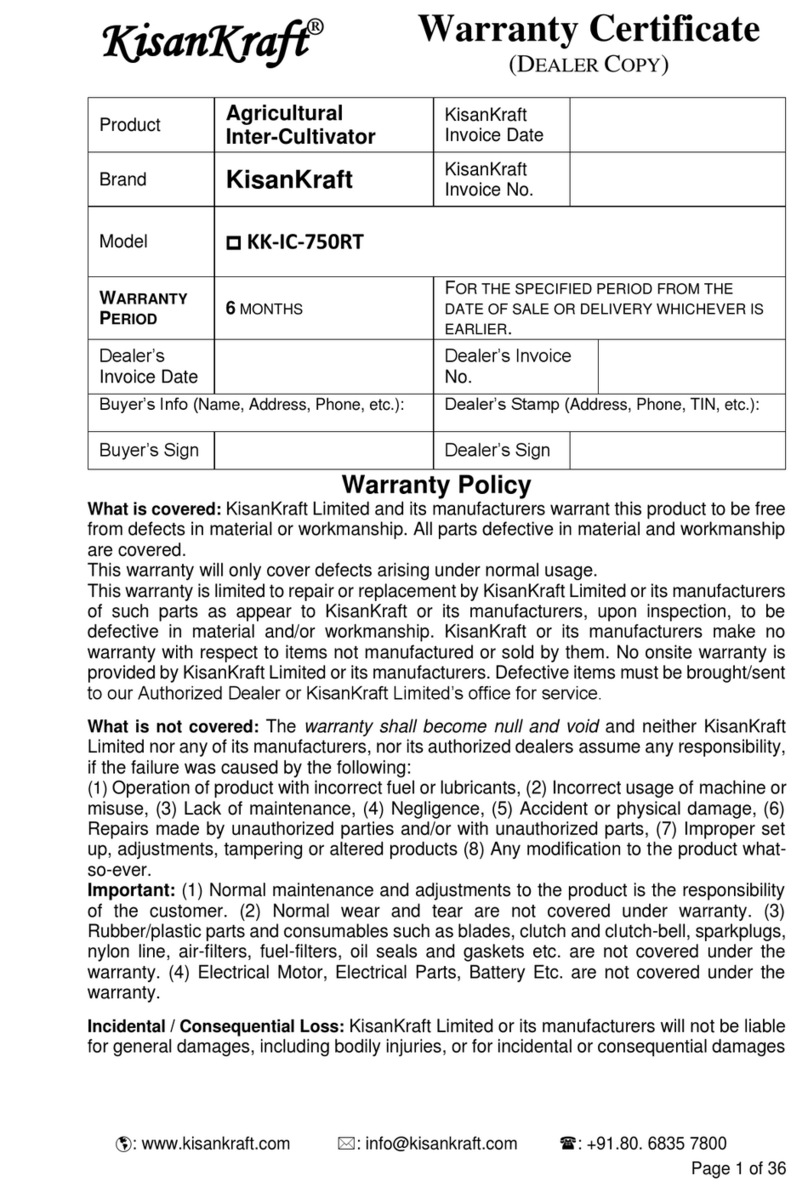

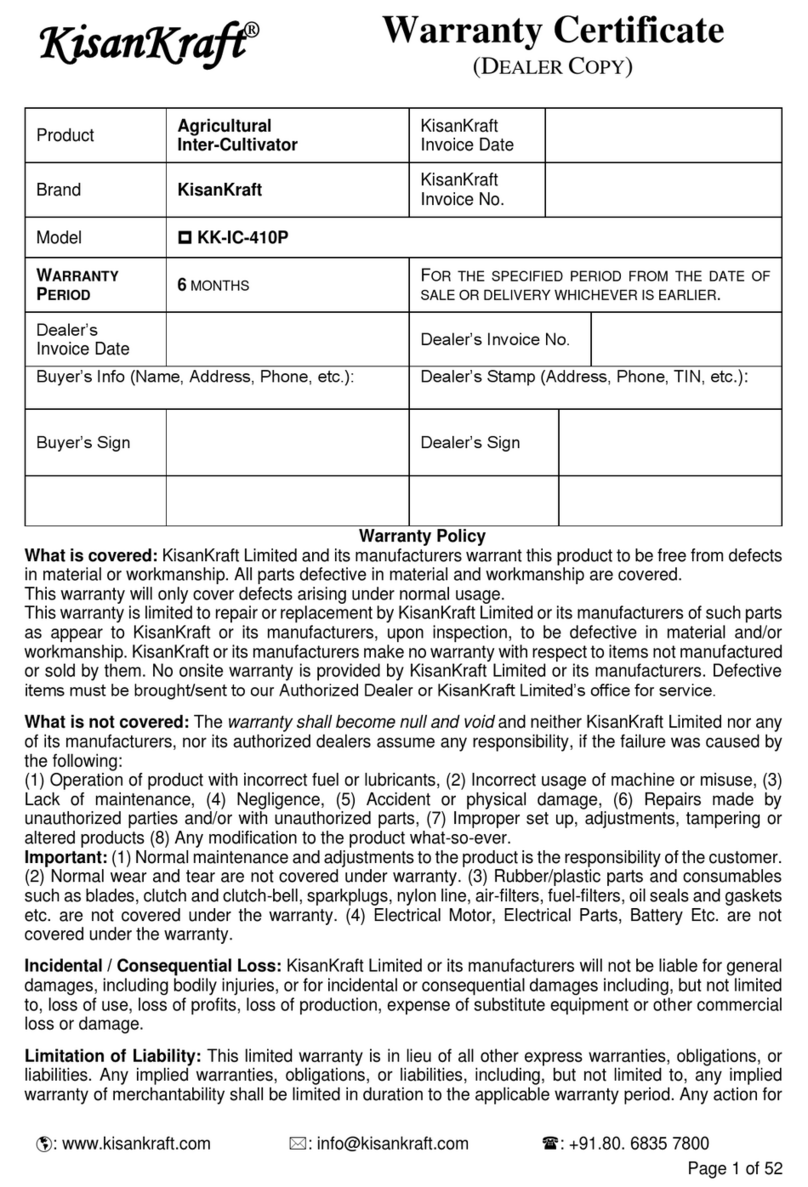

Warranty Certificate

(DEALER COPY)

This warranty is null & void, if you fail to register the warranty with

KisanKraft by sending the KisanKraft Copy with dealer’s stamp.

KisanKraft Limited (formerly known as KisanKraft Machine Tools P Ltd)

Page 2 of 48

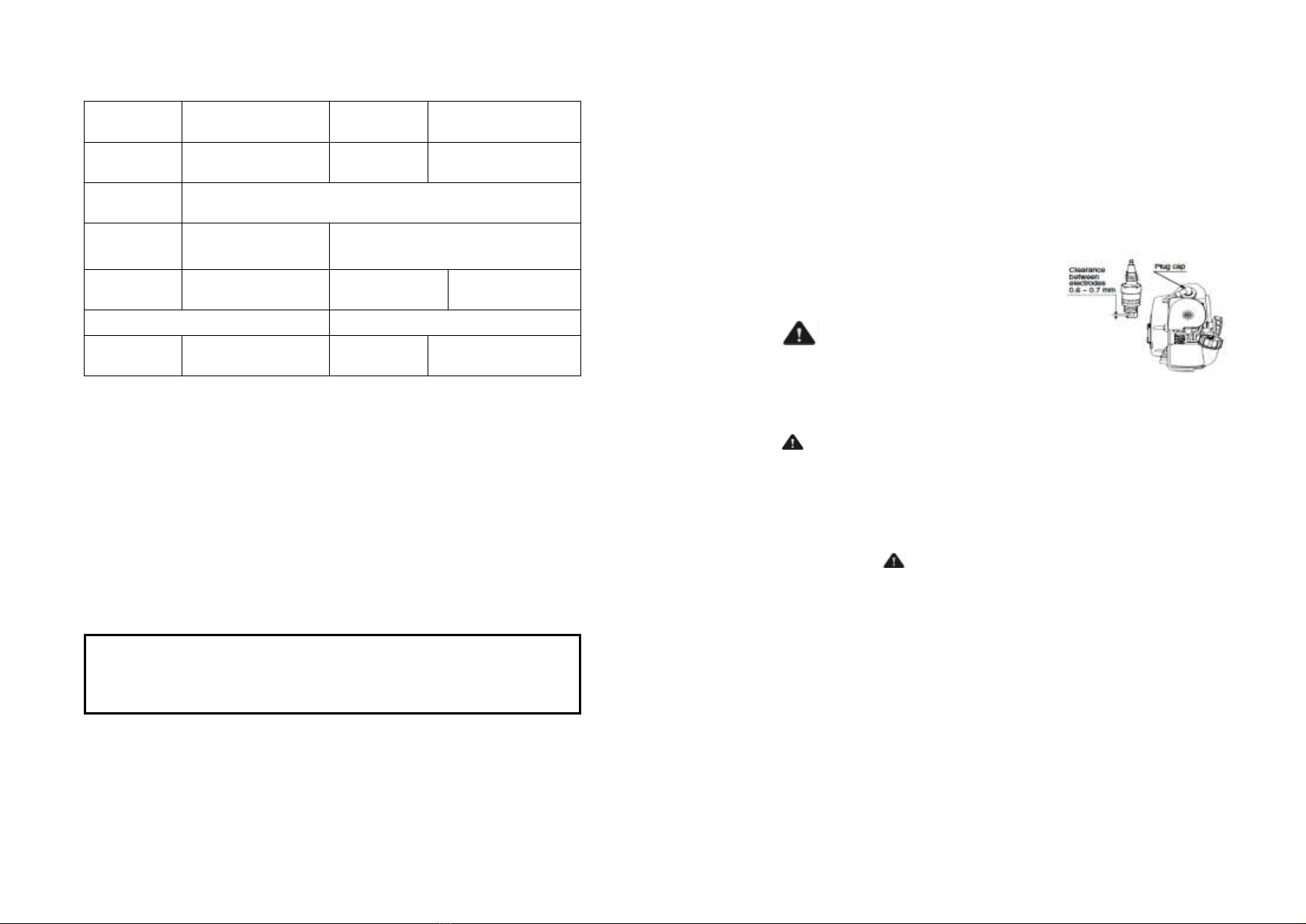

Important: (1) Normal maintenance and adjustments to the product is the responsibility

of the customer. (2) Normal wear and tear is not covered under warranty

(3) Rubber/plastic parts and consumables such as blades, clutch and clutch-bell, spark-

plugs, nylon line, air-filters, fuel-filters, oil seals etc. are not covered under the warranty.

No Warranty On Electrical Motor / Electrical Parts / Battery Etc.

Incidental / Consequential Loss: KisanKraft Limited or its manufacturers will not be

liable for general damages, including bodily injuries, or for incidental or consequential

damages including, but not limited to, loss of use, loss of profits, loss of production,

expense of substitute equipment or other commercial loss or damage.

Limitation of Liability: This limited warranty is in lieu of all other express warranties,

obligations, or liabilities. Any implied warranties, obligations or liabilities, including, but

not limited to, any implied warranty of merchantability shall be limited in duration to the

applicable warranty period. Any action for breach of any warranties hereunder,

including, but not limited to, any implied warranty of merchantability must be brought

within the applicable warranty period.

Modifications of Warranty: No agent, representative, dealer, or employee of

KisanKraft Limited or any of its manufacturers has the authority to increase or alter the

obligations of this warranty.

Assignment / Transfer of warranty: The warranty cannot be assigned and shall not

transfer if the product is resold by the first buyer. The above warranties are extended to

the first end user (original purchaser), and no warranty is made, nor authorized to be

made assignable on resale by the first end user.

What you must do to obtain limited warranty service: To obtain performance of any

obligation under this warranty for failure during the applicable warranty period, deliver

the defective product, to the nearest Authorized Dealer. KisanKraft Limited, its

manufacturers and its dealers reserve the right to inspect the claimed defective part(s)

to determine if the malfunction is the result of a defect covered by this warranty. Please

note that the decision of KisanKraft Limited with respect to any warranty claim is final.

Receipt is required for availing warranty services

Jurisdiction: All disputes are subject to Bangalore court’s jurisdiction.

ChainsawsBrush Cutters and AccessoriesHarvesters

Engines and Water PumpsHand ToolsGardenTools

Cultivators and AccessoriesSprayers and Accessories

Transplanter and Post Hole Digger Milking Machines

Warranty Certificate

(KISANKRAFT COPY)

This warranty is null & void, if you fail to register the warranty with

KisanKraft by sending the KisanKraft Copy with dealer’s stamp.

KisanKraft Limited (formerly known as KisanKraft Machine Tools P Ltd)

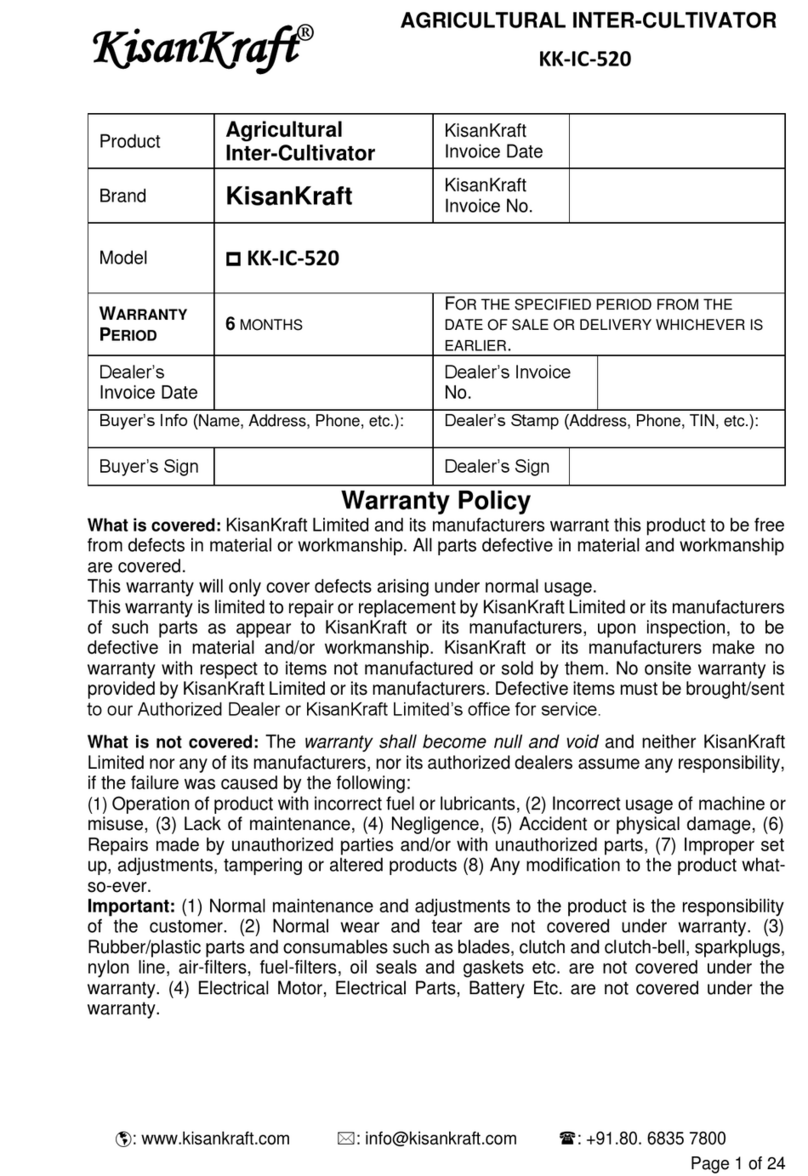

Agricultural

Inter-Cultivator

FOR THE SPECIFIED PERIOD FROM THE

DATE OF SALE OR DELIVERY WHICHEVER

IS EARLIER.

Buyer’s Info (Name, Address, Phone, etc.):

Dealer’s Stamp (Address, Phone, TIN, etc.):

What is covered: KisanKraft Limited and its manufacturers warrant this product to be

free from defects in material or workmanship. All parts defective in material and

workmanship are covered.

This warranty will only cover defects arising under normal usage.

This warranty is limited to repair or replacement by KisanKraft Limited or its

manufacturers at the premises of Authorized Dealers, of such parts as appear to

KisanKraft or its manufacturers, upon inspection, to be defective in material and/or

workmanship. KisanKraft or its manufacturers make no warranty with respect to trade

accessories not manufactured or sold by them.

What is not covered: The warranty shall become null and void and neither KisanKraft

Limited nor any of its manufacturers, nor its authorized dealers assumes any

responsibility, if the failure was caused by the following:

(1) Operation of product with incorrect fuel or lubricants, (2) Incorrect usage of

machine or misuse, (3) Lack of maintenance, (4) Negligence, (5) Accident or physical

damage, (6) Repairs made by unauthorized parties and/or with unauthorized parts, (7)

Improper set up, adjustments, tampering or altered products

Note: The purchase is not contingent upon a product demonstration. The

purchaser shall satisfy himself with the product, including any product

demonstration or verification of any function, before buying. KisanKraft Limited or

its authorized dealers, including online sellers, shall not be liable to give any on-

site demonstration after purchase of any of the product.