7

SAFETY INFORMATION

This tool is NOT electrically insulated.

Contact with a “live” wire will also make

exposed metal parts of the tool “live” and

can result in electrical shock,

electrocution injury or death.

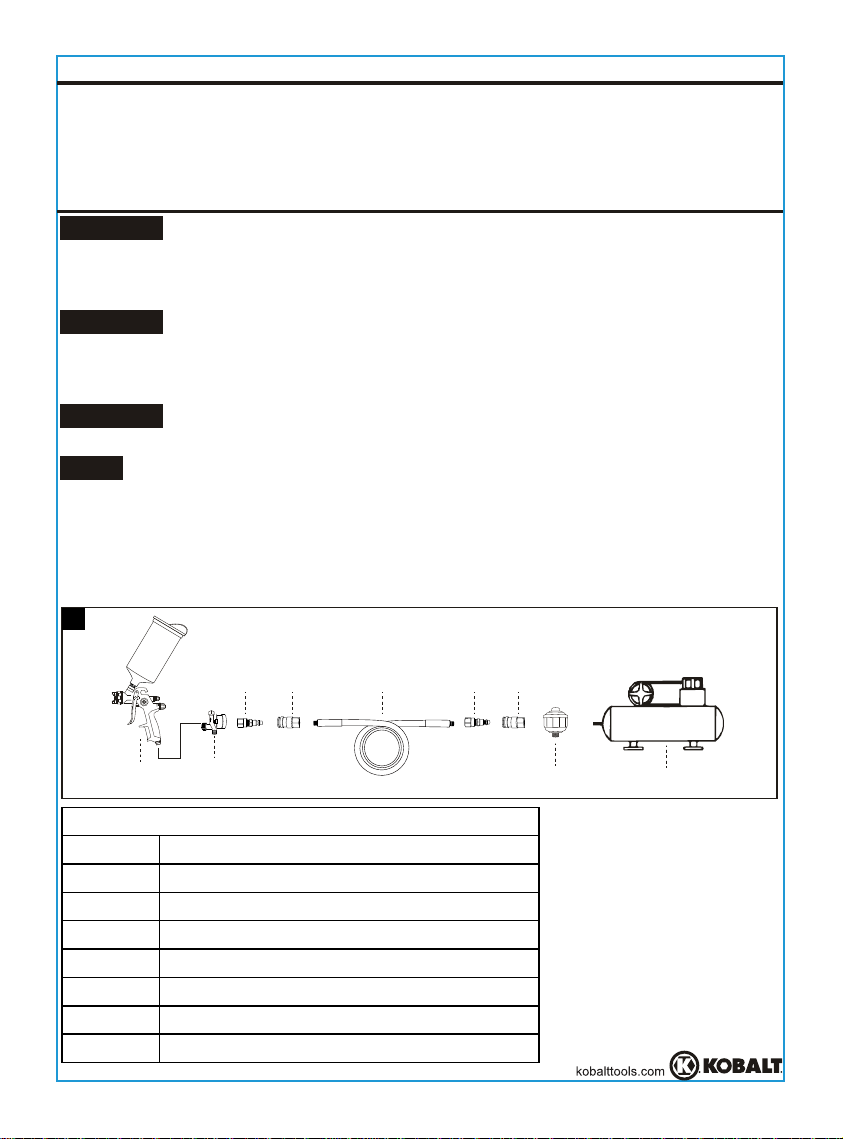

An unattended tool could be activated by

unauthorized/untrained persons, leading

to their injury or injury to others.

Air tools can propel fasteners,

loose/broken accessories or other objects

throughout the work area.

Air tools can become activated by

accident while being handled, during

accessory changes, tool changes,

maintenance or repair.

Disconnect the tool from the air supply

during accessory changes, tool changes,

maintenance or repair.

Never carry the tool by the air hose. Never

yank the air hose to disconnect it from the

tool or the air supply.

Always carry the tool by the handle.

Avoid unintentional operation. Never carry

the tool with the trigger depressed or

engaged. Do not lock, tape or wire the

trigger for continuous operation.

Only an authorized service representative

should do repair servicing.

Maintain awareness of work area safety at

all times. Always be aware of other people

around the work area to ensure safety.

Use only parts, fasteners and accessories

recommended by the manufacturer.

Keep work area clean, free of clutter and

well lit. Do not allow children to operate

any tool, and keep children away from

work areas.

Remove air hose when the tool is not in

use and store tool in a secure location

away from reach of children and untrained

users.

Never use air tools where they may come in

contact with energized electrical wiring.

Avoid body contact with grounded surfaces

such as pipes, radiators, refrigerators, and

ranges. There is an increased risk of

electrical shock if your body is grounded.

Whenever possible, it is recommended that

electrically non-conductive clothing and

non-skid foot wear be worn when using tools.

Risk of Electric Shock

WARNING

WHAT COULD HAPPEN HOW TO PREVENT IT

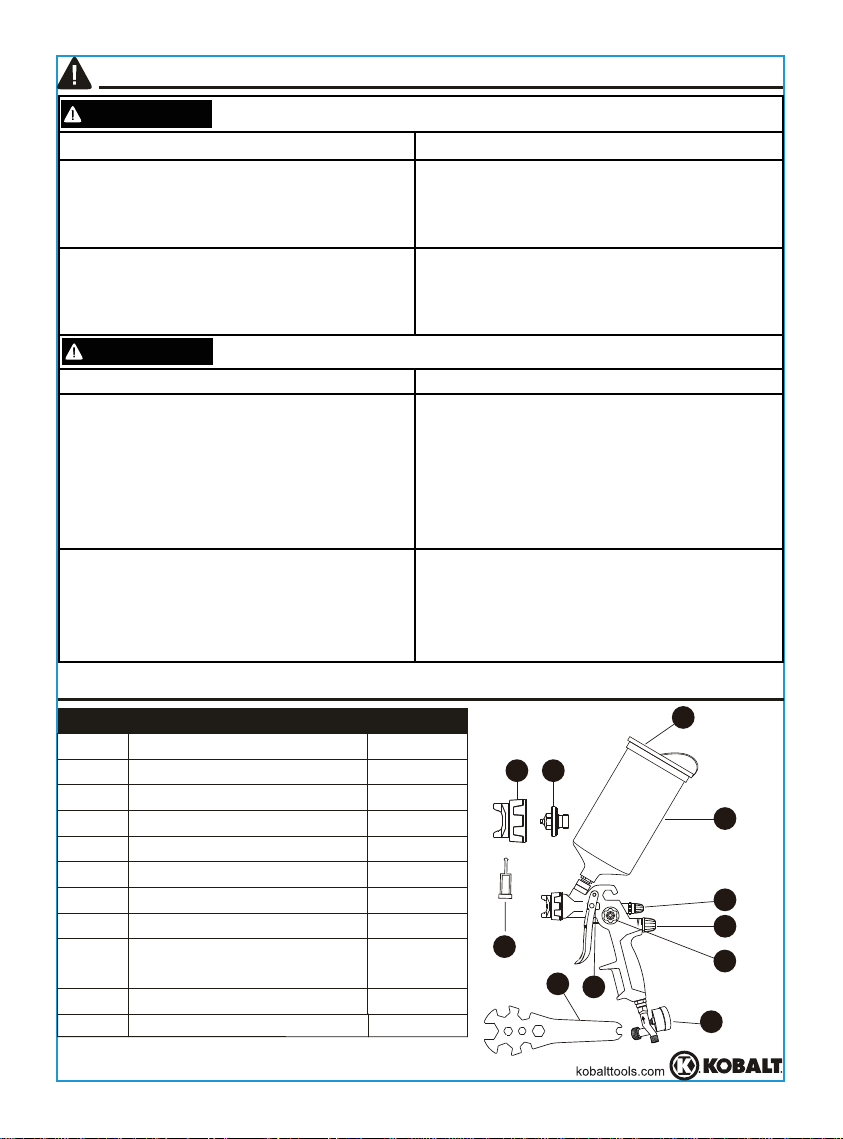

Risk of Personal Injury

WARNING

WHAT COULD HAPPEN HOW TO PREVENT IT