KOBE INDUSTRIAL AIR TOOLS

have been specifically designed to help you work SAFELY

and EFFICIENTLY. Your care and good judgement are the best protection against injury, but always ensure

that the appropriate safety equipment is worn. All possible hazards cannot be covered here, but the most

important ones have been highlighted.

KOBE

INDUSTRIAL

AIR TOOLS

SAFETY INSTRUCTIONS

You have purchased a quality product that is designed for high performance

and long service life. If correct use, safety and maintenance procedures are

observed this machine will last for many years.

Always adhere to the processes and safety

warnings, which are stated in the instruction

manual.

GENERAL OPERATING HAZARDS

Always ensure all users are physically able and

competent to handle the size, weight and power

of the tools and have received appropriate

training to perform the task.

Always avoid accidental starting of the tool by

disconnecting it before replacing accessories or

repairing.

Always be aware of the tool rundown time.

Never allow routine to lead to mistakes.

Never operate if any parts are missing or

damaged.

Never allow untrained persons to operate the

tool.

WORKPLACE HAZARDS

Always ensure your working area is clean and

well lit.

When working at height make sure that the tool

is safely secured and be aware of objects falling

below. Make sure that no persons are working

directly below the working area.

Do not operate in explosive atmosphere, for

instance extreme dust, gases and liquids.

Keep children and bystanders away while

operating the tool. Distractions can cause you to

lose control.

Never run the tool in areas exposed to water or

in damp conditions.

PERSONAL PROTECTION

Always wear approved eye protection during

operation. Use safety glasses or goggles which

conform to BSEN136 or CE equivalent that

provide protection from the front and side. The

operator of the power tool is responsible for

following accepted eye, face, respiratory, hearing

and body protection.

Always ensure that all long hair and loose clothing,

ties, scarves, jewellery, etc., are secured or

removed.

Always consult a doctor if numbness, tingling,

pain or whitening of the skin occurs. Repetitive

work motions, awkward positions and exposure

to vibration can cause “Repetitive Strain

Injuries”.

When operating the tool stay alert and use

common sense, especially when it comes to

working at height. Be aware of what’s below you.

Do not overreach. Keep a proper balance and

footing at all times.

Do not use the tool if under the influence of

alcohol, drugs or medication.

SPECIFIC SAFETY INSTRUCTIONS

Always ensure all accessories are rated to the

“Free” speed of the air tool and intact before

fitting or using.

Always use air tool attachments that are in good

condition and are designed to be used with the

tool.

Always be aware of the risk of crushing between

the tool and the workpiece due to sudden

movement or reaction forces.

Always shut off air supply, drain hose of air

pressure and disconnect tools from air supply

when not in use, before changing accessories or

when making repairs.

Never apply additional or over excessive force to

the air tool.

2

KOBE

INDUSTRIAL

AIR TOOLS

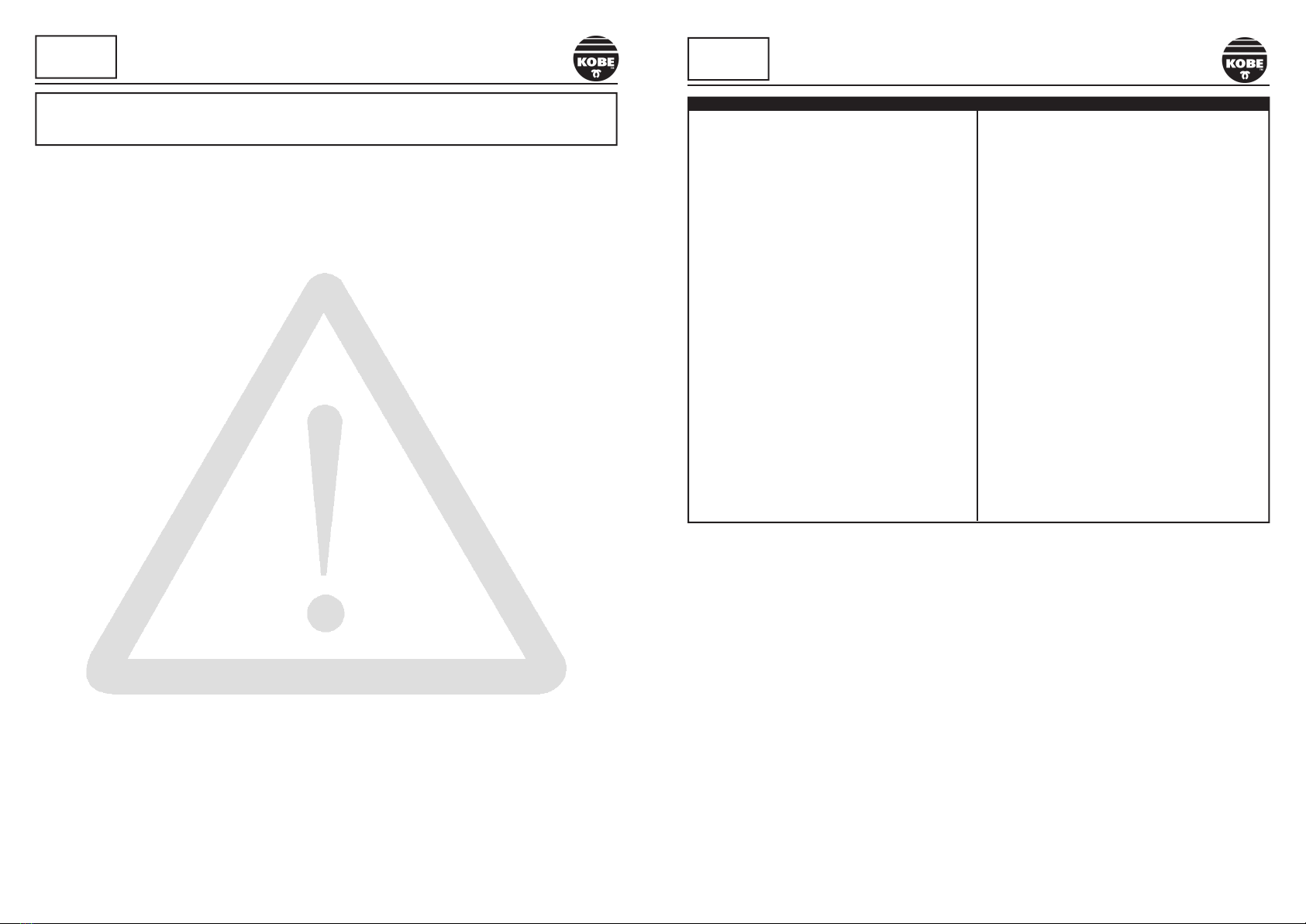

PARTS BREAKDOWN

1 . . . KBE-298-5500A . . Housing

2. . . KBE-298-9302S . . Spring pin (3x18L)

3. . . KBE-298-5502C . . Connection

4. . . KBE-298-5503D . . Throttle lever

5. . . KBE-298-5504E . . Valve pin

6. . . KBE-298-5505F . . Bushing

7 . . . KBE-298-5506G . . Throttle valve

8. . . KBE-298-5507H . . Spring

9. . . KBE-298-1978S . . “O” ring (22.8x2)

10 . . KBE-298-5509K . . Deflector

11 . . CES-298-0696P . . Ball bearing (696zz)

12 . . KBE-298-3762S . . Steel ball (2) (3/32”)

13 . . CES-298-0629D . . Ball bearing (627zz)

14 . . KBE-298-9314S . . Rear end plate

15 . . KBE-298-5514Q . . Rotor

16 . . KBE-298-5515R . . Vane (4)

17 . . KBE-298-5516S . . Idler gear pin (3) (4x15.8L)

18 . . KBE-298-5517T . . Cylinder

19 . . KBE-298-5518V . . Front end plate

20 . . KBE-298-5519W . . Nut

21 . . KBE-298-5609K . . Knob

22 . . KBE-298-5521Y . . Thread ring gear

23 . . KBE-298-5522Z . . Idler gear (3)

24 . . KBE-298-5524A . . Needle bearing (HK0910)

25 . . KBE-298-5525B . . Ratchet housing

26 . . KBE-298-5526C . . Crank shaft

27 . . KBE-298-5527D . . Idler gear plate

28 . . KBE-298-5528E . . Drive bushing

29 . . KBE-298-5529F . . Yoke

30 . . KBE-298-5530G . . Ratchet pawl

31 . . KBE-298-5531H . . Spring cap

32 . . KBE-298-5532J. . . Spring

33 . . KBE-298-5533K . . Washer

34 . . KBE-298-5534L . . Reverse button

35 . . KBE-298-5535M . . Pin (3.3x8.8)

36 . . KBE-298-9347S . . Spring pin (2x5L)

37 . . KBE-298-5537P . . Ratchet anvil 3/8”

38 . . KBE-298-5538Q . . Spring (2)

39 . . KBE-298-3763S . . Steel ball (2) (1/8”)

40 . . KBE-298-5540S . . Thrust washer

41 . . KBE-298-5541T . . Retainer ring (IRTW-22)

42 . . KBE-298-00435 . . Spring pin (1.5x6L)

43 . . KBE-298-5543W . . Fixed shaft

44 . . KBE-298-5268X . . “O” ring (7.5x1.5)

45 . . KBE-298-5545Y . . Washer

46 . . KBE-298-5546Z . . “O” ring (2) (10.7x1.5)

47 . . KBE-298-5548A . . “O” ring (11.4x1.3)

48 . . KBE-298-0016S . . “O” ring (3.8x1.9)

49 . . KBE-298-5550C . . “O” ring (6.5x1.5)

50 . . KBE-298-2177S . . Spring pin (2.5x6L)

51 . . KBE-298-5552E . . Spring pin (2x12L)

52 . . KBE-298-5553F . . Damping material

53 . . KBE-298-5554G . . Ball bearing (689zz)

54 . . KBE-298-5555H . . Rubber grip

55 . . KBE-298-5556J. . . Rubber hat

56 . . KBE-298-5557K . . Specification label

57 . . KBE-298-9902A . . Warning label 29x16mm

58 . . KBE-298-9903A . . Warning label 20x16mm

No. Order Code Description No. Order Code Description